Everything You Need to Know about Transparent 3D Printing

Sometimes, you may want a part to be transparent for aesthetic reasons, and other times, transparency is a functional necessity. In either case, 3D printing’s flexibility in terms of design, materials and processes makes it possible to create parts with a transparent effect. This can be a difficult task since the very principle of the 3D printing, i.e. the superimposition of layers, creates spaces that light cannot pass through. However, transparency is still possible to achieve. Glass, for instance, is great for creating transparent parts and it is emerging as a viable material for 3D printing. But because 3D printing glass is less common, in this article, we focus on plastics.

Before delving into the subject, it is important to distinguish between transparency and translucency. Transparent pieces allow the passage of a greater amount of light without visible distortions, so you can see perfectly through the piece. Translucent pieces, on the other hand, allow diffused light to pass through, meaning that the image we see through the pieces is not completely clear. Here, we will analyze two technologies compatible with transparent plastic materials, the factors to consider with each technology and the applications of transparent 3D parts.

Technologies to Achieve Transparent 3D Parts

Resin-Based Processes

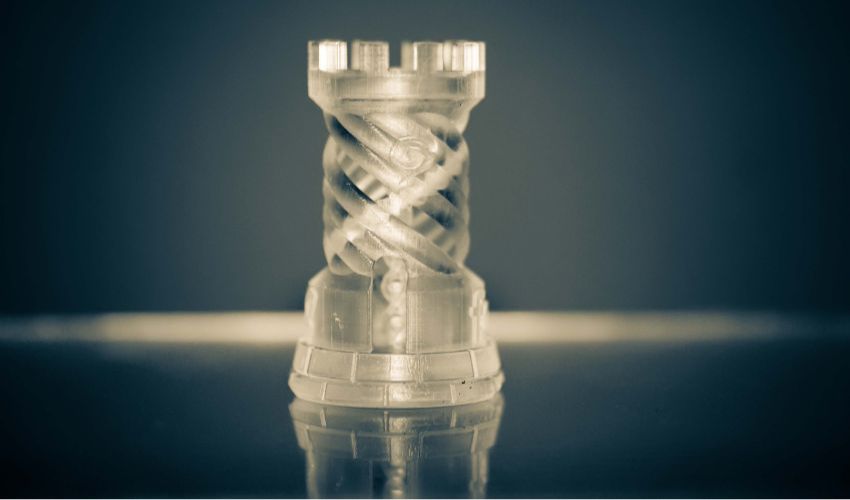

When you think of transparent 3D printing, the first thing that comes to mind is the use of resin-based processes. Vat photopolymerization (SLA, DLP) is one of the ideal technologies for achieving high-quality, highly transparent parts, as the resulting surfaces are smooth and let more light through. There are several transparent resins on the market with properties to suit different clear optics applications. For example, Formlabs Clear Resin for SLA printers is a resin that produces parts close to the transparency of glass, with fine detail and without the need for time-consuming post-processing.

In addition to these processes based on the use of a heat source and a tank, we can add material jetting. This technology makes it possible to use several resins at the same time and to combine different materials. In this way, transparent resins can be loaded into the machine and several levels of transparency can be achieved on the same part. What’s more, material jetting offers excellent resolution and a very smooth surface, enhancing the aesthetic qualities of parts.

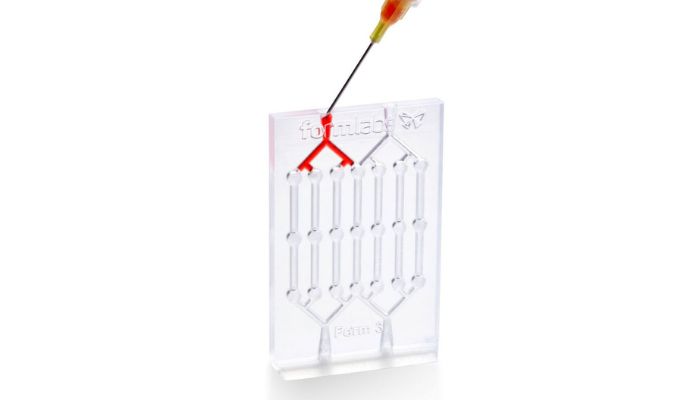

Transparent 3D printing is useful in the study of microfluidics (Credits: Formlabs).

A common disadvantage of resin parts, however, is their tendency to yellow over time or lose clarity after rinsing and drying. To avoid this, it is often necessary to coat, polish and sand parts to make the surface as smooth as possible. In general, a combination of these techniques increases transparency and gloss.

Material Extrusion

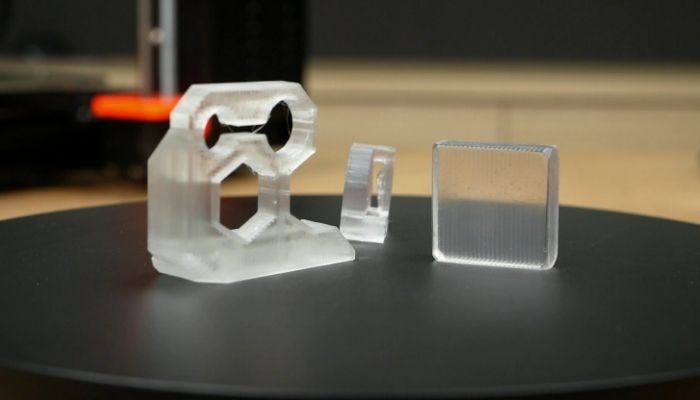

Compared to stereolithography, fused deposition modeling (FDM/FFF) is a more affordable and widely available technology, but it is not capable of obtaining the same degree of transparency. This is because the deposition of material in successive layers scatters light. In this case, the parts are more translucent than transparent. The materials that stand out for transparent 3D printing with FDM printers are PLA, Polycarbonate and PETG. Of these materials, PETG is the most suitable for transparent 3D printing because its molecular structure allows good light transmission.

To print parts with a transparent effect with FDM technologies, there are key parameters to consider. First, reducing the layer height by 0.1 to 0.2 will minimize visible lines and result in a smoother, more uniform surface that can be sanded to a clear effect. It is also important to maintain a continuous flow of material to avoid bubbles and imperfections, as well as to print at a slower speed. A final aspect to consider would be the infill of the parts. Opting for a minimal or even infill structure can allow light to pass through the parts better. As mentioned earlier, the main limitation of FDM in printing transparent parts lies in the difficulty of completely removing layer lines, even after extensive post-processing like sanding and coating.

Transparent parts printed with PETG (Credits: CNCKitchen)

Transparent Part Applications

Transparent or translucent 3D printed parts are popular not only for their look but also for their functionality. For example, you could create prototypes that allow you to observe the inner workings of mechanisms, making the interaction between moving parts or fluids visible. This property is also especially useful in microfluidic devices and in the design of optical systems, like housings for LED lights and light guides. The most popular use of transparent 3D printing is for decorative objects because 3D printing translucent or transparent parts allows designers to create unique parts with glass-like finishes or effects.

Camera with a 3D printed lens (Credits: Formlabs)

Transparency in 3D printing is also very much in demand in the medical sector, particularly for producing surgical models that are as realistic as possible. Healthcare professionals can see the exact anatomy of the patient, and all the blood vessels inside an organ, for example. They are better able to visualize possible risks during an operation and are better prepared. It is also a way of reassuring patients: by showing them a transparent anatomical model, they can better appreciate their body’s inner dynamics.

Transparent and translucent 3D printing opens up interesting possibilities for parts with high optical clarity. The choice of technology and material will depend on the project in mind. In addition to these factors, the use of specific parameters and post-processing techniques will largely determine the degree of transparency achieved.

What are your thoughts on transparent 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.