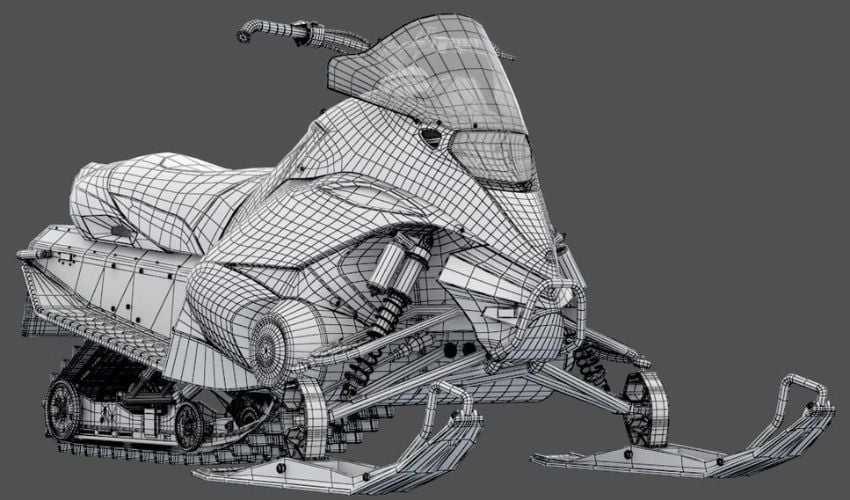

Everything You Need to Know About Polygonal Modeling for 3D Printing

Polygons play an essential role in 3D modeling, allowing the design of complex objects with great precision. By assembling simple geometric shapes, it becomes possible to create a variety of three-dimensional models, particularly suitable for 3D printing. But how do polygons actually work? How are they used in 3D modeling? And what impact do they have on the 3D printing process? This guide provides clear answers to these questions.

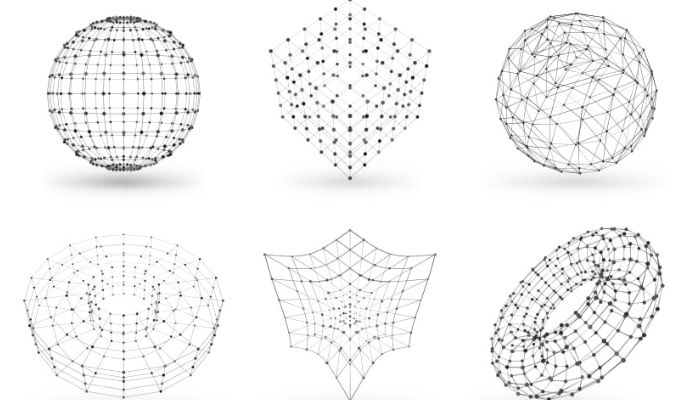

Polygons are two-dimensional planar surfaces used to construct 3D meshes, i.e., lattice structures. They are defined by points, called vertices, positioned in three-dimensional space and connected by edges to create the desired shape. When three vertices are connected, they form a triangle, the simplest and most commonly used polygon. Other shapes, such as quadrilaterals, can also be used, provided they have at least three vertices. By assembling several of these surfaces, we obtain a three-dimensional object whose appearance resembles a mesh, due to the interlacing of vertices and edges. Thus, each polygon forms a closed surface composed of at least three vertices. Polygons with more than four sides, called n-gons, are generally avoided in 3D modeling because they pose compatibility and rendering problems.

Photo Credits: CGI Furniture.

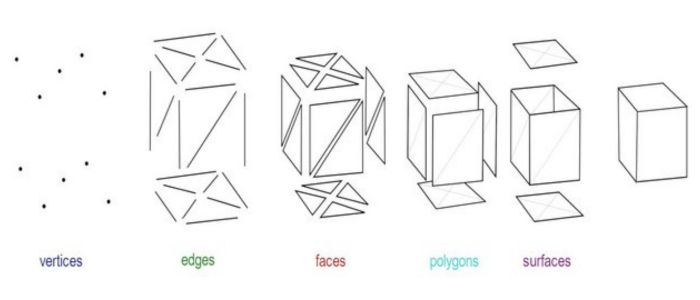

The Parts of a Polygon

Each part of a polygon has a specific role in its structure. Vertices, for example, are the points where two edges meet. When you move a vertex, the edges connected to it also move, changing the shape of the polygon. Edges, on the other hand, are the lines connecting two vertices in 3D modeling software. They serve as a link between vertices and help define the overall geometry of the polygon. Any change to an edge therefore influences the entire structure.

Surfaces, or faces, are created when several edges meet to form a flat, closed area. If a face is moved or deformed, this also changes the vertices and edges that compose it, since these elements determine its shape. In short, in a polygon, all parts are interdependent: changing a single element—vertex, edge, or face—has a direct impact on the entire geometry of the 3D model.

Photo Credits: Université de Colonia.

Polygonal Modeling Techniques

Among the main polygonal modeling techniques are extrusion, subdivision, and beveling. Extrusion involves selecting a portion of a mesh—usually a face or edge—and then stretching it outward or inward. This operation extends the initial shape while maintaining a connection with the existing structure. It is a fundamental method for adding volume and building complex shapes. Subdivision, on the other hand, refines a model by dividing its faces into smaller parts. This involves adding new vertices, edges, and faces, which increases the mesh density and results in smoother and more detailed surfaces. This technique is commonly used to improve the realism of a 3D model.

Finally, beveling is used to soften the sharp edges of an object. 3D models often have very sharp corners that can appear artificial; Beveling rounds these edges to create smoother, more natural transitions. However, this technique must be used with care, as a poorly managed bevel can alter the topology and cause problems in the mesh structure.

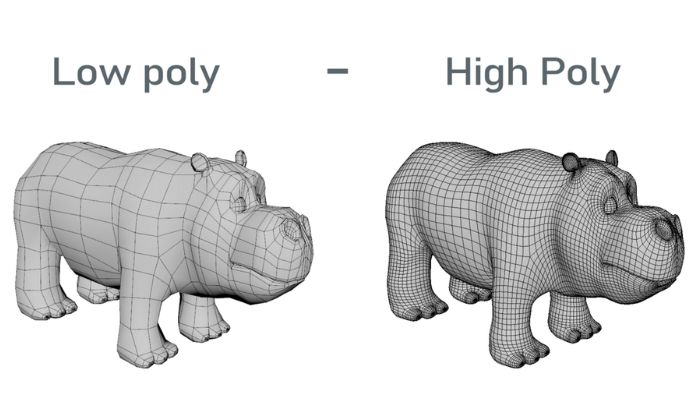

The Difference of Polygonal Densities

In 3D modeling, two types of models are generally distinguished: high-poly and low-poly. A high-poly model is characterized by a very high level of detail and contains a large number of polygons. These models are not always created using traditional polygonal modeling; they are often generated using voxel-based techniques. Voxels, the three-dimensional equivalent of pixels in 2D, are volumetric units that store essential information about shape and material. Voxel technologies allow the creation of 3D objects in real time, which can then be converted into polygonal meshes using automated algorithms. This process results in extremely detailed models, but they generally require significant storage capacity due to their complexity.

Conversely, low-poly models are characterized by a reduced number of polygons. They are widely used in computer graphics, video games, and animation, where performance and display speed are essential. These models are designed to preserve the overall shape and structure of the object while minimizing its geometric complexity. In this context, the concept of retopology is particularly relevant. It is a process that consists of transforming a high-poly model into a low-poly model, using specialized tools. The goal is to simplify the mesh topology while preserving the visual appearance of the object. Complex details are then rendered not through geometry, but through the use of textures and bump maps, which allows for a realistic rendering without overloading resources.

Photo Credit: 3DCoat

The Advantages and Disadvantages of Using Polygons

Understanding how polygons work greatly facilitates 3D modeling. Their simple structure makes them easy to manipulate and assemble, speeding up the creation process. One of the main advantages of polygons is their compatibility with texture mapping, which allows the appearance of surfaces to be modified without altering their geometry. Furthermore, they can often be modeled individually, face by face, simplifying the modeler’s work. Technically, because polygons are formed from straight segments, they allow for the design of surfaces of varying sizes and the creation of flexible and complex shapes.

However, this method also has certain limitations. Creating highly detailed models often requires thousands or even millions of polygons, which significantly increases file size and computational requirements. Furthermore, some specific techniques, such as Paint FX, are not compatible with polygons because they require levels of detail that polygons alone cannot provide. Additionally, modeling very organic shapes can be difficult because the straight edges of polygons limit the smoothness of curves. To simulate a curve, you need to multiply the small straight edges, which increases the accuracy, but also the size and complexity of the file.

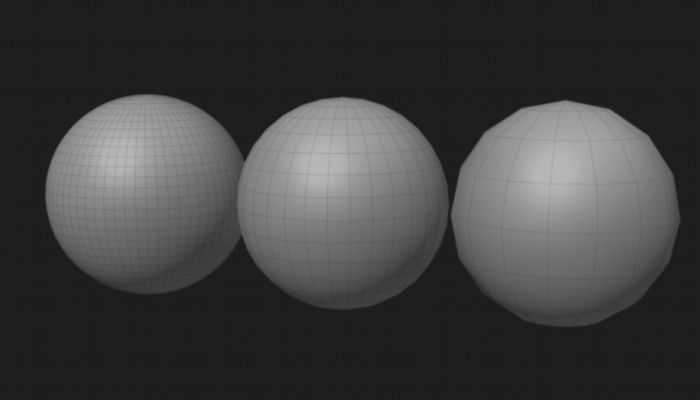

These spheres show how the level of detail affects a model: with 2048, 512, and 128 polygons, the model becomes smoother and more detailed as the number of polygons increases, while fewer polygons result in a less accurate model. (Image credit: University of Cologne).

The Importance of Polygonal Modeling for 3D Printing

The number and arrangement of polygons in a 3D model directly influence print quality and processing time. Models with very high polygon density are often more cumbersome to manage and require more computing power, which can significantly lengthen processing times. Conversely, an overly simplified model with an insufficient number of polygons risks lacking detail and failing to meet aesthetic or technical requirements. It is therefore essential to optimize the mesh by reducing the number of polygons while preserving the essential elements of the model. This optimization helps strike the right balance between visual accuracy and processing efficiency. A well-balanced model not only ensures high-quality printing, but also processing within a reasonable timeframe.

Beyond the simple number of polygons, their orientation also plays a crucial role. Each polygon has an inner and an outer face, and poor alignment can lead to errors during 3D printing. To avoid these problems, careful verification of polygon orientation and model data consistency is strongly recommended before any production release.

Available Programs

Polygonal modeling can be time-consuming. Fortunately, many software programs are designed to simplify the process. Among them, Adobe’s Substance 3D Modeler, based on voxel technology, stands out for its power and ability to create detailed 3D models while integrating functions geared towards polygonal modeling. Polygonica is another solution: this software toolbox specialized in processing polygonal meshes excels at optimizing and managing complex 3D models. Figuro, on the other hand, is an effective tool for modeling and optimizing meshes intended for 3D printing, helping to speed up file preparation. More general-purpose software such as Maya, Blender, or 3ds Max also offer robust polygonal modeling features. Maya, in particular, is often used as an entry point for learning this technique. To deepen your knowledge, check out the following video:

What do you think of polygon modeling for 3D printing? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel

*Cover Photo Credit: Ebal Studios