Everything You Need to Know About Food-Safe 3D Printing

In recent years, 3D printing has been taking the food industry by storm. From the release of Cocoa Press’s highly-anticipated chocolate 3D printer to the continued industrialization of food 3D printing with companies like Revo Foods and Steakholder Foods, using 3D printing for the creation of meat, fish and desserts has never seemed so easy. But using 3D printers to create food is not the only way that additive manufacturing can be used in the food sector. It is also possible to use 3D printing for the creation of parts that come in contact with food, such as plates, cutlery or even packaging. But of course, if a part, even one made with 3D printing, will be used with food, it must be “food safe.”

But what exactly does food safe mean? What are the most important considerations when it comes to 3D printing? In the following guide, we answer these questions as well as take a closer look at how exactly a user can ensure that a 3D printed part is food safe. More specifically, we will be focusing on polymer additive manufacturing since, although ceramics and metals also can be considered food-safe, plastics are often more accessible, especially when it comes to non-industrial additive manufacturing.

3D printed tableware from Joe Doucet (photo credits: Joe Doucet)

What Does Food Safe Mean?

Before we get into food-safe 3D printing, it is important to first define what exactly food safe is. Well in general the term food safe for materials is a status that designates that the material is permitted to come into direct contact with food. Any material that is called food safe will meet certain requirements as determined by the intended use and will not constitute a food-safety hazard. Though these also change based on the country.

For example, in the United States, the regulations for food-safe materials and processes come from the U.S. Food and Drug Administration (FDA). More specifically, the FDA Code of Federal Regulations Title 21 (CFR 21) which covers the substances that can be used as a material for both single and repeated use parts. Meanwhile, in the EU, food safety for polymer materials and articles falls under guidelines 10/2011.

Generally speaking, to be considered food safe, a part must have a few characteristics: must not allow migration of deleterious (causing harm or damage) substances; must not impart colors, odors or tastes; it must be safe under normal use conditions; must be durable, corrosion-resistant and nonabsorbent; needs to be sufficient in weight to withstand repeated washing; should be finished in order to have a smooth, easily cleanable surface without breaks and sharp internal angles; and last but not least must be resistant to pitting, chipping, scratching, scoring, distortion and decomposition. It is therefore these guidelines which must be followed by anyone hoping to use 3D printing for parts that will come into contact with food.

Materials or parts that are food safe are often designated with this universal symbol

Is PLA Food Safe?

Before getting into the processes themselves, one of the most important factors to consider when looking into food-safe 3D printing is the choice of material. This is especially the case for plastics, as concerns have been raised for many in recent years that this family of materials allows the leaching of chemicals into food, not to mention the larger discussion over microplastics in bodies. Still, there are a number of polymers that can be used.

The most widely used polymer in 3D printing at home is undoubtedly PLA. The material is prized for its ease of printing as well as its biodegradability (under the right conditions). But can it come into contact with food?

Well, there is not an easy answer. Technically, pure PLA with no color or other additives is defined as food-safe by the FDA. However, if PLA is colored, then these additives can leach chemicals, thus making it no longer food safe. There are also other factors that make it less than suitable.

Notably, we can point to the material’s low melting point, which makes it unsuitable for parts that may come into contact with heat (for example a coffee mug or something designed for the microwave). It also means that it cannot be put in the dishwasher, nor washed properly, meaning that the part may need to be single use to avoid bacterial contamination. These factors make PLA not the most food-friendly material, even if it is included as a safe material by the FDA.

Of course, PLA is not the only material that could be considered food safe. Others on the FDA’s list of food-safe polymers include polypropylene, PETG (PET is the material used for plastic bottles, though with PETG, like PLA, it is only food safe if additives such as color are not present in the filament), PA11, PA12 and silicone. These more industrial materials may be a safer bet than a standard thermoplastic like PLA.

Parts made by Prusa to test food safety (photo credits: Prusa Original 3D Printers)

Added to that, many material manufacturers, such as BASF and igus, have their own food-safe range of materials which fulfill all conditions. However, even if a material is food safe, that does not mean that the resulting part will be. That depends as well on the process that was used to make it.

How to Ensure Food-Safe 3D Printing

As mentioned, materials are only the first step to ensuring food-safe 3D printing. Even if you are using FDA-approved materials, the 3D printing process itself may contaminate the part and mean that it will no longer be considered food-safe. Let’s look at how using FDM, SLS or resin 3D printing can impact the final part.

FDM 3D printing is still the most popular process today and is the one that we are most likely to see for makers when it comes to making parts that may come into contact with food. But the process itself is not necessarily food safe. That is why certain considerations should be kept in mind.

First, in terms of a nozzle, most 3D printers will have a brass nozzle. But some of these have been found to contain trace amounts of lead. The safest bet is to a stainless-steel nozzle, as this material is approved by the FDA and will not contain a PTFE tube (as Teflon is toxic at high temperatures). A direct extruder, rather than a Bowden, is also recommended. Additionally, it is critical that before 3D printing any part that is destined for food, that the 3D printer be cleaned thoroughly, getting out any remaining material that may be toxic as well as ensuring there is no bacterial growth.

That being said, even with all these safety considerations, FDM 3D printing is not considered to be an extremely food-safe 3D printing process. That is because due to its nature, gaps will be left in the part, notably among the layers. These in turn can become areas for bacterial growth, therefore making the part no longer food safe. It is for that reason that parts made using FFF for food are recommended to be single use, or subject to post-processing.

Food-safe coating can help make 3D printed parts more suitable for use with food (photo credits: The Epoxy Experts)

Smoothing and then coating with a food-safe material, for example epoxy resins or silicone coatings, will seal cracks and pores. This results in a watertight surface that will prevent food particles from becoming stuck and making washing easier. However, be sure to keep in mind that these coatings also wear down over time, meaning that even if a part is not single use, any 3D printed polymer part should not be in contact with food over a long period of time or be used extensively.

That being said, coating can also be used with other 3D printing processes as well to make them more food-safe. Take SLA 3D printing for example. Generally, resin 3D printing processes are not considered food safe as resins are toxic, even if the final parts are smoother than those made with FDM. However, if covered with a food-safe coating afterward, they could be used for this purpose.

A similar issue arises with SLS 3D printing. Though the process is significantly more food safe than many others (as you can avoid issues related to nozzles or resins), especially when printing with nylon, the parts are still porous. Therefore, again, food-safe coatings are strongly recommended to seal the part.

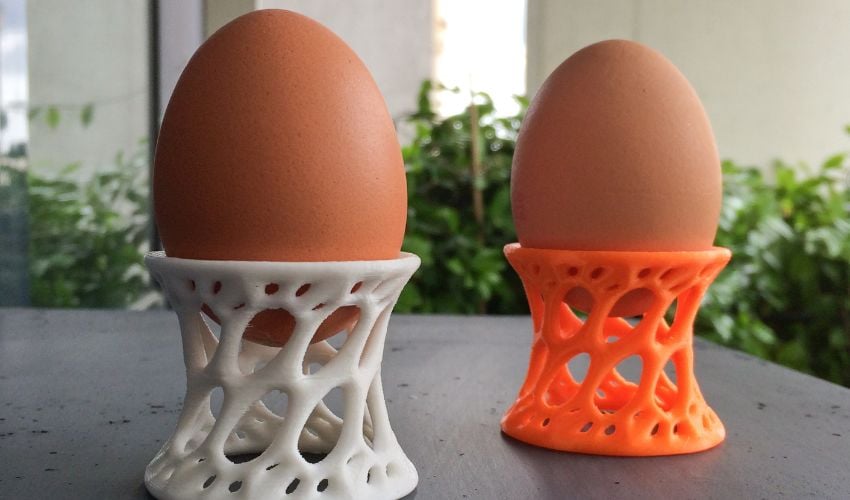

In any case, it is safe to say that although it is certainly possible to have food-safe 3D printing, it is not without its risks. Safety considerations must be the utmost priority when it comes to anything touching food in order to ensure the health of the person eating, which is why everything that comes into contact with any consumable item goes through so much testing. Still, if you keep these factors in mind and ensure that you are using food-safe materials, you can look forward to using a 3D printer to make parts like novelty cookie cutters or even cutlery.

What do you think is the most important consideration for food-safe 3D printing? Do you make parts that come into contact with food? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Gregoware on Cults