Everything You Need to Know About 3D Printing Zirconia

Zirconia, or zirconium dioxide (ZrO2), is a crystalline ceramic material renowned for its excellent resistance to impact and wear, as well as for its aesthetic qualities. Most often machined, notably for dental applications, zirconia can also be 3D printed to create more complex shapes. But which additive manufacturing processes are compatible? What specific features need to be taken into account? What are the advantages of 3D printing zirconia? We tell you all about it!

Zirconia is obtained by heating compounds of zirconium to very high temperatures. Zirconium is a chemical element discovered in 1789 by the chemist Martin Heinrich Klaproth, and it was first isolated as a metal in 1824. The process of calcining zirconium yields zirconia, which is of great interest to many industries. It is a particularly fracture-resistant ceramic, with good biocompatibility and excellent aesthetics. It is often used to design dental prostheses. Zirconia is resistant to chemicals, liquids, gases, high temperatures and corrosion.

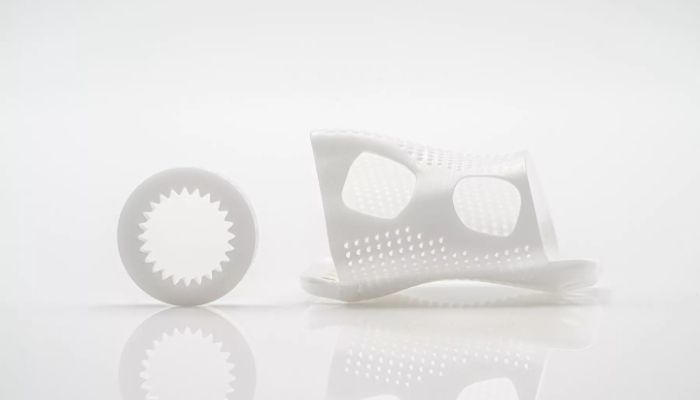

3D printed pieces with the LithaCon 3Y 210 material from Lithoz (Photo Credits: Lithoz)

3D Printed Zirconia

When we talk about additive manufacturing and zirconia, we find many similarities with aluminum oxide and alumina. Zirconia comes in the form of a powder that can be used in several printing processes. Let’s start with extrusion. Here, the powder is enclosed in plastic filament, meaning that it is an indirect process. The part that comes out of the 3D printer is therefore not final, because the piece has to go through debinding and sintering stages to remove the plastic. It must be cleaned thoroughly and then passed through an oven to consolidate the zirconia particles, thus obtaining the material’s final properties. Sintering prevents the formation of defects and small cracks on the parts, reinforcing the material.

Zirconia in 3D printing can also be found in resin form, thanks to photopolymerization processes like SLA and DLP. With these methods, we can obtain precise and fairly dense zirconia parts. In terms of density, zirconia has a higher density than alumina, which increases its overall weight. Here, too, considerable post-processing is required.

It should be noted that zirconia is generally considered more difficult to print than alumina. This ceramic is also often more expensive, even though its characteristics are quite similar to those of aluminum oxide.

Zirconia can be 3D printed through different processes (Photo Credits: KUAIPRINT)

Possible Applications

Zirconia is currently particularly popular in the dental sector: it’s an opaque white material that’s biocompatible, has low thermal conductivity and is aesthetically pleasing. This makes it ideal for dental prostheses and crowns. Lighter than metals, it perfectly imitates natural teeth. For the moment, zirconia is machined rather than 3D printed for the dental sector, due to certain regulations and certifications.

If we look at applications for zirconia in 3D printing, let’s mention the medical market more generally. Combined with the flexibility of additive manufacturing and its customization possibilities, the biocompatibility and fracture resistance of zirconium dioxide are particularly interesting. The material will also be used for applications in electronics, jewelry and manufacturing. Its excellent chemical inertness and shock resistance are particularly noteworthy.

Would you 3D print with Zirconia? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Zetamix

Considering 3D binder-jet printing components for our invention of a device that converts waste plastic into electricity. It has two thermal reactors subject to high temperatures.