Epson Officially Enters the 3D Printing Market

It’s hard not to have heard of the Japanese group Epson, especially when it comes to 2D printers. And today, it particularly interested us because the electronics giant is taking an unexpected turn in the additive manufacturing market. The company is expected to unveil its first 3D printer in two days at the International Robot Exhibition 2022, 8 years after a first announcement made by its president, Minoru Usui, to move into the market. This new solution is an industrial machine based on an extrusion process. The main difference is the use of a flat screw as a nozzle to expand the range of materials available and the amount of material deposited.

In January 2014, on the occasion of the group’s 30th anniversary, Minoru Usui had revealed his intentions to enter the 3D printing market within the next 5 years. At the time, Epson considered that the technology still had many limitations, particularly in terms of compatible materials. Since then, the market has evolved significantly and we only need to see the number of companies specialized in 2D that have taken the gamble of moving into additive manufacturing. There is of course HP which is a major player in the industry, but also Canon and Xerox. It is now Epson’s turn to market its new machine after internal use.

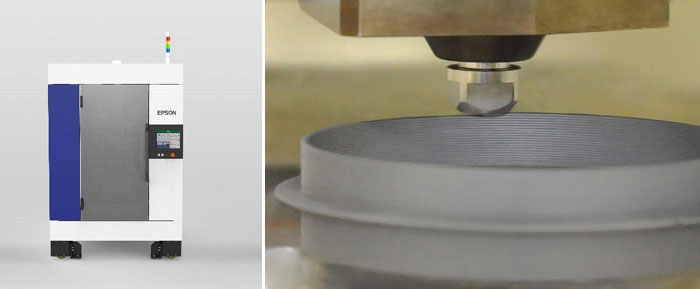

The Epson machine is based on an extrusion process (photo credits: Epson)

Epson has remained rather discreet about this new industrial 3D printer. We know that it will be based on an extrusion method made possible by a flat screw. The manufacturer specifies that it is the same as found on its injection molding machines – so these are proven and reliable components. The use of such a screw especially allows to widen the range of compatible materials by proposing a 3D printing based on granules, plastic or metallic, but also from high performance polymers like PEEK. The manufacturer states in its press release:

In addition, the amount of material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed. The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength. Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy

It is an industrial machine, designed for the production of high quality finished parts. It will be presented for the first time from Wednesday on the Epson booth at the international robotics exhibition in Tokyo. The Japanese giant will perhaps reveal more details that we will not fail to follow you! In the meantime, find the press release HERE.

What do you think of Epson’s entry into the 3D printing market? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.