EOS releases four new materials for series additive manufacturing

EOS has released four new materials to open up new applications in metal additive manufacturing. The four new metal materials are EOS StainlessSteel CX, EOS Aluminium AIF357, EOS TitaniumTi64 Grade 5, and EOS Titanium Grade 23 and they should have applications in sectors from automotive to medical. The company is providing companies with transparency and documentation about its materials for them to compare Direct Metal Laser Sintering (DMLS) with traditional manufacturing methods – for example, providing great detail on the mechanical properties of each material.

Currently, the global company offers a range of 20 different metal materials, and is launching 4 more. Hannes Gostner, Director Research and Development at EOS said, “At EOS, the development of systems, materials, process parameters, software, and services has always gone hand in hand. All of the elements are perfectly aligned to each other. The result is reproducible high-quality parts at a competitive cost per part. This combination is of crucial importance, particularly for series manufacturing.” In other words, EOS believes that additive manufacturing is ready for industrial scale production.

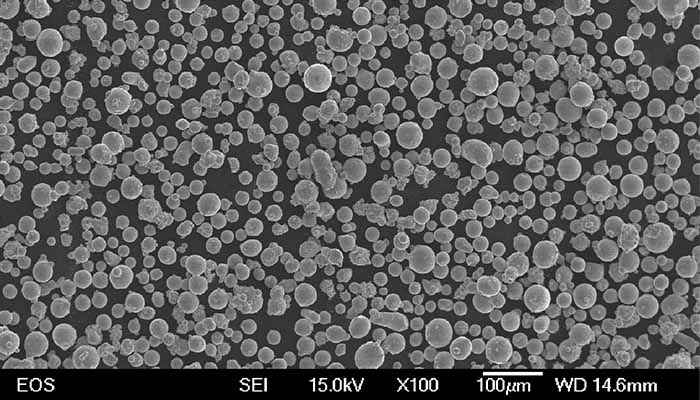

The four materials introduced, namely one stainless steel, one aluminium and two grades of titanium are all designed for use with DMLS 3D printing. Each material comes with data such as the number of test specimens on which the mechanical properties are based on, as well as detailed scanning electron microscope (SEM) images that provide an insight into the quality.

A SEM image of EOS StainlessSteel CX | Source: EOS

Details on the new materials

“EOS StainlessSteel CX is a new tooling grade steel developed for production with the EOS M 290 that combines excellent corrosion resistance with high strength and hardness. Components made from this material are easy to machine and enable an excellent polished finish.

EOS Aluminum AlF357 is the ideal material for applications that require a light metal with excellent mechanical/thermal strength. Components made from this material are characterized by their light-weight, corrosion resistance and high dynamic loading. EOS Aluminum AlF357 has been specially developed for production with the EOS M 400, but it is planned to also make the material available for the EOS M 290 system in the near future.

EOS Titanium Ti64 Grade 5 has been specially developed for its high fatigue strength without hot isostatic pressing (HIP). Suitable for production with the EOS M 290, the material also offers excellent corrosion resistance, making it ideal for aerospace and automotive applications.

EOS Titanium Ti64 Grade 23 has also been specially developed for its high fatigue strength without hot isostatic pressing (HIP) and for production with the EOS M 290. Compared to Ti64, Ti64 Grade 23 offers improved elongation and fracture toughness with slightly lower strength. Thanks to these properties, it is particularly well suited to medical applications.”

Finally, EOS has graded its materials in terms of Technology Readiness Levels (TRL) – first introduced by NASA as a way of classifying technological maturity – and the four materials can be considered PREMIUM materials ready for series production (i.e. TRL between 7 and 9). In fact, it is the company’s aim to push for mass production by providing materials that have the correct properties to facilitate and accelerate this transition.

You can find more information HERE.

What did you think of these new materials? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!