EOS Announces its Strongest Aluminum Alloy, EOS Aluminium Al2139 AM

Around Formnext, we always expect a flurry of announcements from companies in the additive manufacturing sector. Leading German supplier for industrial 3D printing EOS is no exception. Recently, the company announced the addition of a new material, EOS Aluminium Al2139 AM. The alloy is said to be EOS’ highest strength AM aluminum alloy, lending it to interesting applications in sectors like automotive and aerospace, among others.

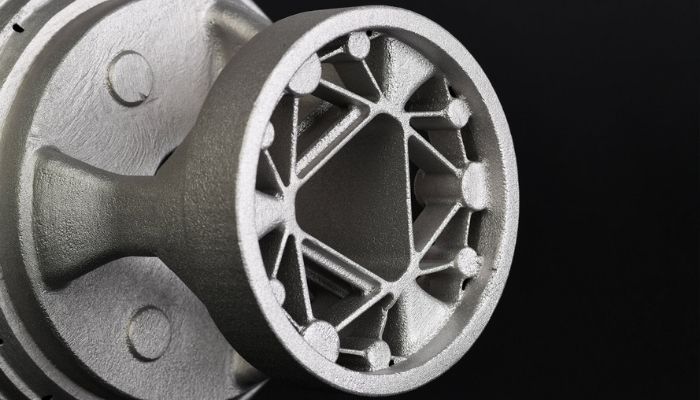

Aluminum has long been considered a material of interest in additive manufacturing. This is due to its use in a number of sectors, notably aerospace and automative, thanks to its lightness, strength and chemical resistance. Already, it can be seen being used in applications by the US Air Force, Boeing, Mercedes-Benz, Airbus, all of whom employ aluminum alloys for 3D printed parts. What is particularly interesting about this latest material is that it was engineered specifically for use in additive manufacturing. Additionally, not only does it have the highest strength properties compared to EOS’ other AM aluminum alloys, but it also outperforms many others currently on the market.

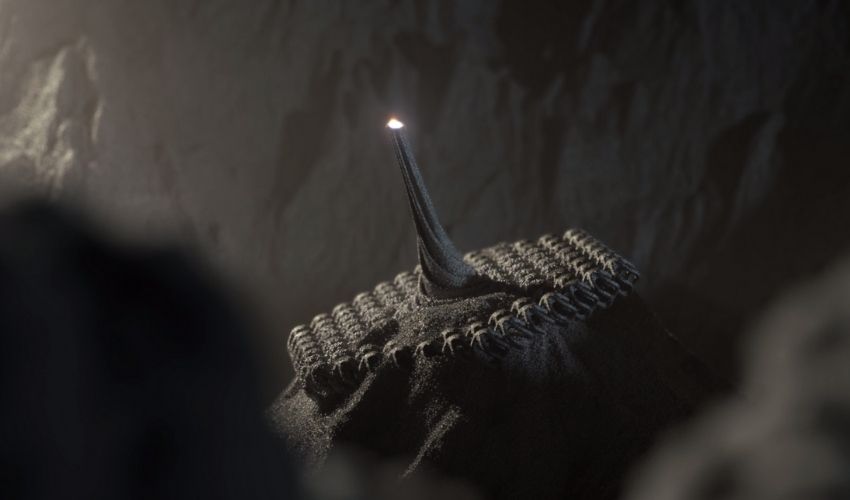

A part made using EOS Aluminium Al2139 AM (photo credits: EOS)

What do we know about EOS Aluminium Al2139 AM?

As mentioned, the alloy was specifically made by EOS to be used in additive manufacturing. And it has a number of properties that will make it useful in many industries. For example, it has outstanding performance of elevated temperatures of up to 200ºC and has an excellent strength to weight ratio. In fact, in its heat treated state, it can reach a yield and tensile strength of around 500 MPa which is the highest strength for an AM aluminum alloy. This in particularly would allow users to reduce the weight of parts, a critical benefit for many sectors including aviation, transportation, racing and the space industries. EOS also points to its importance for the contract manufacturing sector.

The material has been created in powder form and though the press release does not specify, it should be assumed that it is compatible with DMLS (Direct Metal Laser Sintering), a powder bed fusion process. This is because that is the particular expertise of EOS. Furthermore, EOS noted that thanks to its fast and simple single-step heat treatment procedure, users can expect to save up to 88% in active heat treatment time, meaning that lead times can be shorter, a critical benefit of AM which is not always evident when using laser powder bed fusion.

Parts made with the alloy can be made lighter without compromising strength according to EOS (photo credits: EOS)

Sascha Rudolph, Senior Vice President for EOS Metal Materials, commented, “At EOS we are constantly striving to improve the performance of our customer’s manufactured parts, whilst reducing the amount of material needed and streamlining production processes. EOS Aluminium Al2139 AM is a culmination of those efforts to put new materials innovations in the hands of manufacturers.” You can find out more information about the material in EOS’ press release HERE.

What do you think of EOS Aluminium Al2139 AM? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.