Can UCLA engineers make environmentally friendly concrete?

Last week, it was reported that a group of UCLA engineers received a $1.5 million grant to make environmentally friendly concrete – by environmentally friendly they mean that it will incorporate carbon dioxide, a greenhouse gas, as part of a binder. By incorporating the greenhouse gas into the manufacturing process, the resulting product could reduce the carbon footprint by up to 60% compared to similar products. Additive manufacturing technologies are beginning to enter the construction industry and could change the manufacturing process for buildings. Of course, materials for these construction 3D printers also have a long to evolve.

The grant was received from the National Science Foundation and Mathieu Blauchy is the principal investigator of the grant. He is a computational materials scientist and an assistant professor of civil and environmental engineering at the UCLA Samueli School of Engineering, he explains: “Concrete is by far the most manufactured material in the world, however its large carbon footprint is a major detriment toward its continued use in its current form”. In fact, it is estimated that the process to make cement, which binds concrete, accounts for about 8% of global man-made carbon emissions.

UCLA Campus

Therefore this grant should provide the resources to study and provide solutions to an environmentally friendlier solution. “This grant allows us to leverage recent developments in artificial intelligence and machine learning to design a more sustainable product. We aim to help construction—a conservative, empiricism-based industry— evolve into a knowledge- and data-intensive industry of the 21st century” adds Mathieu Blanchy.

For now, the team of engineers will focus on conducting simulations and experiments. In order to create concrete that is more sustainable, they will have to understand and control how slurries of cement flow to enable their use in 3D printing. An important challenge will be figuring out how to maximize the amount of carbon dioxide being incorporated in this process. Finally, another area of focus will be using machine learning to discover new 3D printed structures that will offer high load-bearing capabilities, while still being lightweight.

The grant will support graduate students and postdoctoral scholars, and will also allow the team to train undergraduate students. You can find more information HERE.

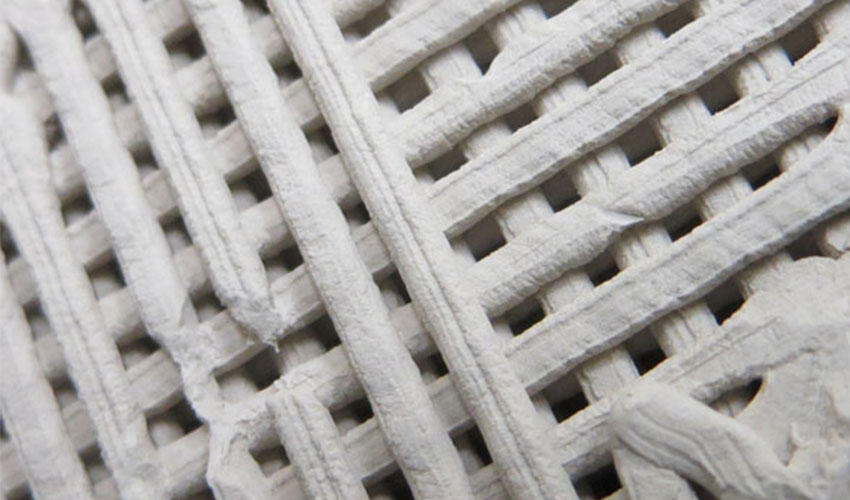

*Cover Image: Prototype samples of 3D-printed concrete. The cube is about 1 square inch in volume | Credits: UCLA Samueli Newsroom

What do you think of this research project to make environmentally friendly concrete? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!