Dynamic 3D Printing Method Achieves Unmatched Speed and Accuracy

Relying on the speed of light, researchers at Northwestern University have developed a remarkably faster photopolymerization-based 3D printer. The researchers claim to be able to deposit 4,000 layers in just 2 minutes! But that’s not all: this 3D printer, equipped with a robotic arm, is able to move and rotate each layer during the printing process. This in turn results in the creation of parts which give the impression of movement and dynamism, otherwise impossible to achieve. So how does this dynamic 3D printing method work?

As you know, all 3D printing processes commence with the modeling of the desired final part, which is then sliced into different horizontal layers, according to a precise plan. Shortly thereafter, these layers are deposited onto the print plate, from bottom to top, to create the final structure. Depending on the size of the structure and the machine used, the manufacturing process is more or less long and precise. Northwestern’s team sought to dynamise this “routine” by providing the ability to manipulate the original design layer by layer and rotate the print direction without recreating the model. Cheng Sun, associate professor of mechanical engineering at the McCormick School of Engineering, explains, “The 3D printing process is no longer a way to merely make a replica of the designed model. Now we have a dynamic process that uses light to assemble all the layers but with a high degree of freedom to move each layer along the way“.

Conventional 3D resin printers create successive layers to design the part. (Photo Credit : DWS)

How does this process work?

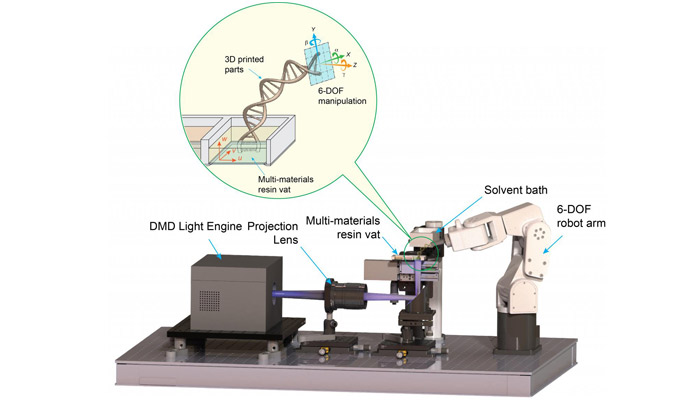

The method developed by Cheng Sun and his team relies on a DLP 3D printer equipped with a robotic arm. As such, the machine is not confined by a Z-axis. Instead, it is able to dynamically alter the printing direction. The DLP 3D printer functions just like a classic resin machine, in that it uses the heat of a video projector to selectively cure a liquid photopolymer. In this case, the advantage of using DLP technology is its ability to polymerise an entire layer at once, rather than point by point as a laser would. This makes it easier for the system to run continuously, and is well evidenced by the team’s claim that they can print 4,000 layers in two minutes.

Cheng Sun added: “This is a very fast process, and there is no interruption between layers. We hope the manufacturing industry will find benefit in it. The general printing method is compatible with a wide range of materials.” This implies that the process can combine different resins- a first on the stereolithography market. However, the team remain very discreet on this point. Nonetheless, they claim to have 3D printed a flexible pneumatic clamp with a rigid base and flexible actuating appendages, evidencing the use of different materials. Other test pieces created by the machine include the famous Eiffel Tower and a double helix.

This method of dynamic 3D printing is relies on the use of a robotic arm. (Photo Credit : Northwestern University)

This is just one of several additive manufacturing innovations to have come out of Northwestern University. From other methods of accelerating 3D printing processes to bioprinted ovaries and the impact of the 3D printed resins on reproductive health, the institution has been a plentiful source of research with significant applications to a variety of sectors. Now, Cheng Sun hopes to not only be able to apply this 3D printing method to other technologies on the market but also to subtractive manufacturing processes. This could offer significant opportunities for the manufacturing industry. You can find the official press release HERE.

*Cover Photo Credit : Northwestern University

What do you think about this novel dynamic 3D printing method? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!