More Durable and Efficient Lithium Batteries Made by Additive Manufacturing

We have known for years that vehicles with internal combustion engines, which produce polluting emissions, are very dangerous for our environment and our planet. It is therefore not surprising that we are increasingly interested in electric vehicles. The environmental advantage is obvious: Eco-friendly driving. In this case, there are no local CO2 emissions, but when it comes to producing the batteries for those vehicles, it becomes a whole different story. In order to move toward an even greener future, the U.S. Department of Energy (DOE) has awarded approximately $1.5 million in funding to Ampcera and Lawrence Livermore National Laboratory (LLNL). The goal is to improve the performance and energy density of lithium batteries through additive manufacturing and to make them more economical and sustainable.

Lithium batteries can be considered the heart of any electric car. They are largely responsible for its operation. Although such a battery contributes to the operation of an environmentally friendly car, it does have its drawbacks, including the environmentally unfriendly extraction of raw materials, as well as the fact that the lithium battery is considered flammable and requires cooling. In order to eliminate at least some of these drawbacks, the U.S. Department of Energy has stepped in.

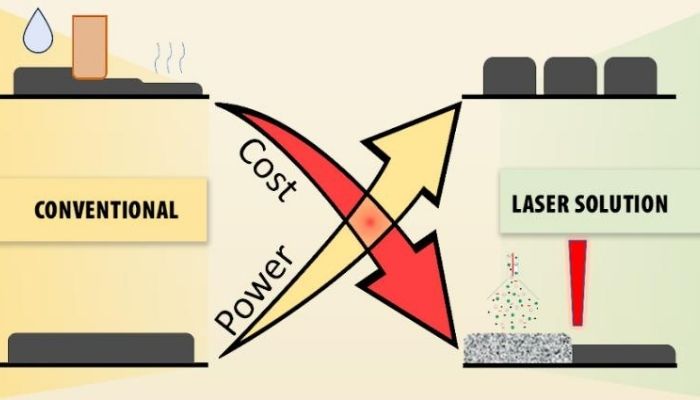

The goal is to reduce costs and increase performance (photo credits: LLNL)

The Benefits of a Lithium Battery Produced via AM

Ampcera is considered an innovative supplier to the lithium battery market and, in collaboration with Lawrence Livermore National Laboratory, this project is one of six energy systems projects selected for an award from DOE’s Advanced Manufacturing Office. The focus is on reducing industrial emissions and, therefore, producing clean energy technologies. This goal is to be achieved through additive manufacturing, as it is considered to be very energy efficient. With a reduction in lithium battery manufacturing costs of more than 50%, additive manufacturing is expected to be more than 10 times more efficient than traditional manufacturing methods. In addition, the production of lithium batteries by 3D printing is also expected to increase energy density to over 450 Wh/kg and reduce costs to less than US$75 per kWh. However, nothing is known about the process used.

According to LLNL, the company is particularly banking on additive manufacturing, as it is considered a more environmentally friendly process and also allows large 3D cathode structures to be processed with high capacities. Conversely, it would mean that lithium batteries could achieve a fast 80 percent charge in as little as 15 minutes or less. Co-investor Hui Du, chief technology officer and co-founder of Ampcera, is optimistic about the partnership with LLNL: “The partnership between LLNL and Ampcera will accelerate the development and commercialization of the ultra-fast and low-cost L-PBF additive manufacturing technology for high-performance lithium battery manufacturing. After developing 3D-structured cathodes, we expect to expand the technology to anode design and also further explore its application in all-solid-state Li metal batteries with even higher energy and power densities.” If you’d like to learn more about this innovative green project, click HERE.

What do you think of these 3D printed lithium batteries? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.