Drexel Electric Racing Relies on SolidCAM to Create End-Use Parts for Race Cars

Training in additive manufacturing is essential in order to ensure that those working in a wide variety of fields are at the forefront of current technological advances. For this reason, many companies in the market have educational offerings for all those interested in adopting 3D printing, regardless of the industry they are targeting. A clear example of this is in the automotive sector, where the Drexel Electric Racing team has participated in the “SolidCAM Additive Challenge”. This is a challenge in which aspiring university engineers have access to the latest 3D printing technologies in order to optimize their production processes. Thanks to this, the students were able to create final parts for their race car that will participate in Formula SAE competitions.

The Drexel Electric Racing team is mainly dedicated to the manufacturing of electric race cars. Formed by a group of students, they carry out the entire production of the vehicles, from design to manufacturing and subsequent quality testing. Once the construction process is completed, the all-electric, single-seat race car is taken to a competition in Michigan and used to compete against other university teams in FSAE events. These types of competitions encourage the use of new technologies by younger generations. Here, undergraduate and graduate students learn to conceive, design, produce and race small formula-style vehicles. Now, thanks to SolidCAM’s training and solutions, the Drexel Electric Racing team has been able to explore the possibilities of metal 3D printing, creating final parts for their single-seater race car.

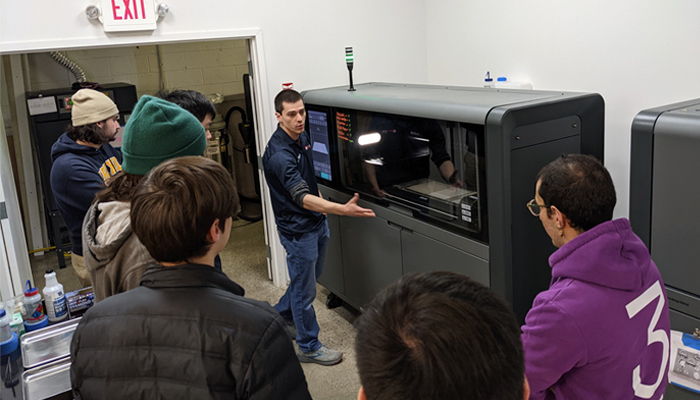

Peter Genovese with a group of students

Drexel Electric Racing’s Use of 3D Printing

When competing in an SAE event, the final cost, the technology used and the design of the models, as well as the functionality of the vehicle, must be taken into account. Through the SolidCAM Additive Challenge proposed by the company, students have access to additive manufacturing solutions, as well as guidance in solving any type of problem they may encounter. This broadens their vision of manufacturing to approach it in a new way, eliminating the limitations of traditional methods. As a result, the Drexel Electric Racing team were able to go to SolidCAM’s hybrid manufacturing center in Newtown, Pennsylvania, to create final parts for their race car. To do so, they had a budget of $1,000 in material costs.

Peter Genovese, Additive Engineer at SolidCAM, was responsible for presenting the challenge to the team, showing them the workshop and desktop solutions for metal 3D printing, as well as the technology’s supporting hardware. Genovese explained, “The Challenge inspires students to create parts for additive technology beyond the plastic printers they have access to on campus. Each additive technology has its own advantages and design guidelines that Drexel Electric Racing was able to capitalize on.” With the goal of encouraging the use of 3D printing, the SolidCAM team shared all the knowledge and hands-on experience needed to fully leverage the benefits of metal additive manufacturing.

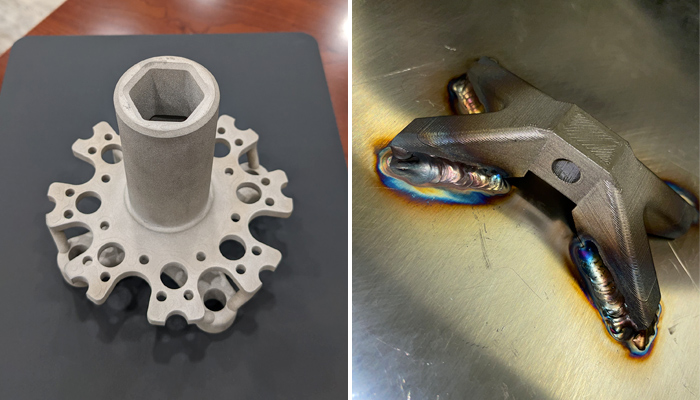

Two examples of 3D printed parts made with SolidCAM’s manufacturing solutions

The students worked with two methods to create the final parts: metal binder jetting and Bound Metal Deposition™. In addition, they experienced the importance of proper post-treatment for the parts. The team depowdered the parts and observed how they were discharged from the furnace after sintering. Using these production systems, the students created two steel back spindles and steel battery holders. Additional material was added to the spindles as compensation to allow for finishing using CNC machines, creating truly hybrid parts. The battery mounts by contrast could be used as printed and welded to the body of the vehicle. In addition, they also used a resin 3D printer from manufacturer ETEC to create the steering wheel grips. In this way, the students were able to optimize their vehicle and put the capabilities of new manufacturing technologies into practice.

The Importance of Training in the Industry

More than ever, it is critical to provide engineering students with hands-on opportunities to develop skills that they will use in their future careers. This in turn will allow more and more companies to embrace 3D printing as a complement to traditional large-scale manufacturing. For nearly 4 decades, SolidCAM has helped train the next generation of professionals. Now, additive manufacturing is the perfect step to further enhance its educational offerings. Kenny Betz, part of the SolidCAM EDU team, concludes, “We were happy to partner with Drexel Electric Racing and share our knowledge of both CNC Machining and Additive Manufacturing to enhance their capabilities and looking forward to continuing the sponsorship into the future.” You can find out more about SolidCAM and their educational offerings on their website HERE.

Depowdering of the parts

What do you think of Drexel Electric Racing’s hybrid approach to created end-use parts for race cars? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: SolidCAM