Dr. Markus Nemitz Talks 3D Printing and Swarm Robotics

A few years ago, we told you about an incredible project to create 3D printed robots for search-and-rescue operations. The man behind it, Dr. Markus Nemitz, has not stopped there. In the time since, Dr. Nemitz has continued to use additive manufacturing in his work in swarm robotics, with the goal to use these soft robots for everything from explosive ordnance disposal to amphibious operations. We sat down with him to learn more about his work.

3DN: Could you introduce yourself and your work?

Markus Nemitz, PhD

My name is Markus Nemitz, and I am an Assistant Professor of Mechanical Engineering at Tufts University, specializing in the design, fabrication, and control of swarm robots including their deployment at points of impact. My research combines expertise in swarm robotics, from my PhD, and soft robotics, from my postdoctoral work at Harvard.

My group focuses on the rapid design, fabrication, and deployment of robots, particularly multi-material systems and fluidic circuits, with applications ranging from underwater vehicles to legged robots. We develop libraries of modular robot components and novel fabrication processes that enable “single-click” manufacturing. Our work also applies machine learning to close the loop in 3D printing—transforming a traditionally open-loop process, where layers are printed without inspection or correction, into one with real-time monitoring and adaptive control.

3DN: Your PhD was in swarm robotics—what attracted you to the subject?

What first drew me to swarm robotics was the elegance of simple agents working together to produce complex, coordinated behaviors. Nature offers countless examples of such collective intelligence—whether in ant colonies, bird flocks, or fish schools—and I saw in these systems a blueprint for scalable, resilient robotic networks.

Many critical applications could benefit from this biological approach if realized at scale: large-area searches for missing aircraft such as MH370; locating survivors beneath rubble, as after the 2023 earthquake in Turkey; distributed sensing for monitoring glaciers, where current measurements are sparse, especially at depth; large-scale explosive ordnance disposal, which disproportionately affects children; and planetary exploration, such as deploying swarms of robots on Mars.

In each case, deploying large numbers of robots is essential—but only feasible if the robots are inexpensive and robust. Achieving this cost-effectiveness, has been a longstanding challenge—one we are only now beginning to overcome for legged robots.

3DN: Why did you decide to adopt 3D printing for your research? Did you consider other technologies?

I adopted 3D printing because it enables rapid iteration and seamless integration of soft and rigid components in a single manufacturing step—capabilities that traditional methods like molding or machining cannot match in terms of complexity, speed, or flexibility. While I previously used techniques such as soft lithography and laser cutting, they lacked the scalability and design freedom essential for fabricating multi-material robots.

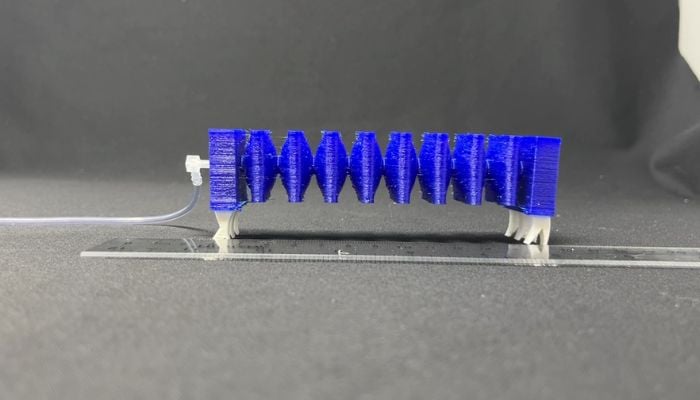

A 3D printed linear actuator made by Dr. Nemitz and his team

However, the potential of fused filament fabrication (FFF) for robot development is immense: from a few spools of filament with varying material properties, we can autonomously produce underwater robots, legged robots, and other complex systems. The process is repeatable, highly automated, and minimizes human involvement, reducing error and improving scalability. More importantly, FFF enables direct integration with design discovery processes such as evolutionary algorithms, where machines autonomously develop and optimize new robots based on user-defined objectives.

Our long-term vision is a warehouse of networked 3D printers capable of printing, testing, and recycling prototypes, with algorithms evolving robot designs in closed-loop systems. We are also exploring thermoplastic recycling in conjunction with fused granulate fabrication (FGF), further increasing sustainability and reducing material costs in this process.

3DN: What kind of 3D printing technology and materials do you use, and why?

As mentioned above, we use multi-material fused deposition modeling (FDM) and fused granulate fabrication (FGF) with tool changers to print elastomeric thermoplastics. These processes give us precise control over mechanical properties such as Shore hardness and flexibility, enable the 3D printing of conductive materials for circuit traces and sensors, and allow us to embed components mid-print—an essential capability for fully integrated designs. Critically, they are cost-effective, which is fundamental when developing low-cost, scalable robotic systems.

FGF is particularly powerful, enabling the 3D printing of elastomeric materials with softness comparable to silicones, while leveraging the manufacturability and recyclability of thermoplastics. It allows us to avoid processes that are expensive and require post-processing steps in order to maintain a streamlined, single-click fabrication workflow. FDM and FGF uniquely offer this level of automation and scalability at an unmatched price point.

3DN: Could you explain soft robotics and how it is central to the robots’ success?

Soft robots stand in stark contrast to traditional robots. While conventional robots are made from rigid materials, soft robots are constructed from elastomeric materials that can deform and absorb impact, making them far more resilient to physical forces. In nature, most biological systems—humans included—are hybrids of soft and rigid structures; our stiff bones provide support, while soft tissues like skin and fat absorb shocks and protect us from injury. This biological model makes soft, hybrid robots a compelling area of study.

I believe that all robots in the future will be hybrids to varying degrees, combining soft with hard materials. Most importantly to us, soft robots are inherently material systems—their function arises from the interplay between material properties and design. This makes them ideally suited for additive manufacturing, which allows us to fabricate complete, integrated robots in a single process without complex assembly. Once you recognize that intelligent systems can be fabricated through multi-material FFF, you realize the immense potential contained in just a few spools of filament—where the design defines the intelligence, and the use case shapes the machine.

A 3D printed fluidic transistor that has been turned on

3DN: Where are you at in the development of your robots? Do you know of any future projects where they may be used and how?

We are currently advancing from lab-scale prototypes to field-ready systems. In our most recent study, we demonstrated a proof-of-concept legged robot that is predominantly 3D printed and combines both stiff and soft materials, leveraging the advantages of traditional and soft robotics. Soft robots are typically resilient to impact but slow, while legged robots are often faster but fragile—and both are traditionally time-consuming to fabricate. By combining both approaches, we create robots that are resilient, capable of fast locomotion over challenging terrain, with the added benefit of being manufacturable at scale through our process.

We are also exploring fluidic sensors, actuators, and controllers for these systems. Why? Because they can be entirely 3D printed, with their function—whether sensing, computation, or actuation—determined by design alone. By integrating fluidic channels into 3D-printed structures, we can build all three: sensors, logic gates with memory elements, and actuators. These logic and memory components give rise to combinational and sequential logic and, thereby, state machines, providing embedded low-level control capabilities.

Over the past five years, I have focused on a specific application: explosive ordnance disposal. Landmines are a pervasive and enduring legacy of war, responsible for killing and maiming up to 1,000 to 2,000 people every month, most of whom are civilians and children. Today, an estimated 110 million landmines remain active across approximately 70 countries and territories. These weapons can lie dormant for decades, waiting for an unsuspecting victim. In collaboration with a military contractor, we tested a proprietary sensor technology on an inert minefield in Oklahoma, detecting landmines buried as deep as one meter.

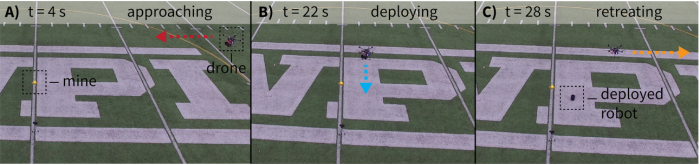

In another project, we deployed our 3D printed robots from high altitudes; they survived free fall and successfully navigated to a dummy mine. We also developed a demining robot for the feature film Rule Breakers, currently in cinemas. The wheeled robot was designed and built in just one week, shipped to Budapest, and operated on set under director Bill Guttentag. The film tells an inspiring story of a group of Afghan women who competed in FIRST Robotics competitions despite immense challenges at home.

I remain committed to advancing explosive ordnance disposal through the development of scalable, low-cost robotic systems. Far too many civilians—and disproportionately children—continue to die because of landmines. To end their use, we must defeat the economy of war by making robotic demining cheaper, faster, and more accessible than deploying landmines themselves.

The research group was also recently awarded a $1,711,191 grant from the Office of Naval Research to advance the development of crab-inspired robots over the next four years. These will be used for aerial deployment and amphibious operations. Similar to the other projects, will be leveraging multi-material FFF to design soft-legged robots while also exploring reinforcement learning for robust, environment-adaptive control. It is a huge step forward and comes thanks to the groundwork of my research group.

A test of 3D printed demining drone

3DN: If these robots could be used for diverse situations, from environmental monitoring to search and rescue operations, how do you envision their manufacturing process and delivering them to the correct site? How would AM play a role?

Our robots are 3D printed, but just as importantly, they can be rapidly adapted. Combining these two capabilities allows us to develop large numbers of robots, each quickly customized for the specific challenge at hand. This approach enables the deployment of specialized robot swarms for mission-specific tasks.

Consider the Tham Luang cave rescue in Thailand as an example. When the soccer team was trapped deep within the cave system, the world watched and hoped. The work we are doing aims to make crowd-solving possible in such scenarios.

Starting from our expanding library of modular components, a global community could design robots tailored to the unique conditions of any disaster. With highly parallelized print farms, we could fabricate and test the most promising designs in real time. Once an optimal solution is identified, the robots can be produced immediately. Every country could have its own manufacturing facility, or, when necessary, one could be deployed rapidly to the point of need. Transferring a digital file takes seconds, allowing fabrication of a robot designed in Boston to be started in Thailand within minutes.

This concept extends even further: when humans go to Mars, they will inevitably face unexpected challenges. Those challenges can be relayed back to Earth, where teams can collaboratively develop and optimize robotic solutions and transmit the designs back to be 3D printed on-site—whether as a single robot or an entire swarm. In short, the power of a spool of filament is immense; it can become any robot you need for a specific problem, with the world community as its collaborative designer.

3DN: What challenges have you encountered while developing robot swarms, and how have you overcome them?

During my PhD, I was driven by the desire to control large numbers of robots in the real world. I quickly realized that most swarm robotics research remained in simulation, while the subfield of swarm engineering grapples with the practical challenges of building physical robots. In my view, the greatest challenge in swarm engineering is pushing the capability of individual robots without increasing their cost.

Traditionally, greater robot capability comes with higher cost, often reaching a point of diminishing returns where significant expense yields only marginal improvements. In swarm engineering, we aim to maximize intelligence and functionality for a given cost, finding the optimal balance where a robot is as capable as possible within strict resource constraints.

I found soft robotics to be a particularly fascinating research area for this challenge. A well-designed, 3D-printed soft robot can achieve enhanced functionality without increasing its cost—its capability is embedded in its design and material properties rather than dependent on expensive components. Embedded machine learning is another promising path we are exploring.

During my PhD, I published a study demonstrating time-series classification on a constrained microcontroller to interpret environmental signals. This proof of concept showed that, with proper training, sensors can be made multifunctional, extracting more information from simpler hardware.

One key technical hurdle has been 3D printing airtight structures for robots operating with pressurized air. We addressed this through a closed-loop printing process, using laser scanning and cameras to monitor the print and correct errors in real time. This approach is particularly novel for soft materials, where we have made important early contributions.

Closed-loop, multi-material printing will be critical to ensuring high-fidelity fabrication in different locations around the world, maintaining consistent quality without reliance on expert operators. I believe, the time when 3D printing experts were necessary to produce high-quality parts is coming slowly (or quickly) to an end; non-experts are going to manufacture complex systems at expert quality. To further address the challenge of airtightness in 3D-printed systems, we also developed custom print nozzles capable of extruding concentric tubes—another creative solution to a longstanding problem.

Ultimately, I believe creativity is the key to progress in swarm engineering. Printing legged robots from multiple soft materials was one such breakthrough that has brought us closer to our ultimate goal: the rapid design, fabrication, and deployment of robotic systems at points of impact to address humanitarian crises.

What do you think of Dr. Nemitz’s research into 3D printing and swarm robotics? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Dr. Markus Nemitz

you’re envisioning a future where 3D printing is more reliable, accessible, and capable of producing complex, high-quality parts without needing specialized expertise. Is that right?