Don Schumacher Racing empowered by new collaboration with Stratasys

Stratasys announced that it will collaborate with one of the most elite competitive motorsport teams, Don Schumacher Racing to empower it with advanced FDM 3D printing technology. Don Schumacher Racing joins the growing list of Stratasys customers using additive manufacturing to become more competitive in high-performance environments. In fact, integrating 3D printing should help accelerate design iterations, workflows and final part production extensively.

The largest auto-racing organisation in the world saw the benefit of adopting FDM to meet the demands of complex, high-requirement racing. Don Schumacher Motorsports, the production segment of Don Schumacher Racing is currently leveraging both the Stratasys Fortus 450mcTM 3D printer and F370TM 3D printer and high-performance materials. Scott Cutler, Senior Manufacturing Engineer, Don Schumacher Motorsports said, “With Stratasys 3D printing in place, anytime a crew chief has an idea for a project or concept part, we can design it, print it out, and test fit and function rapidly at a low cost – whether it’s a prototype or final part. Thanks to 3D printing, we’re able to be more innovative – which equals consistent performance on the track.”

The Fortus 450mc 3D printer from Stratasys has been imagined for demanding applications and high-performance materials | Source: Stratasys

What parts will be 3D printed?

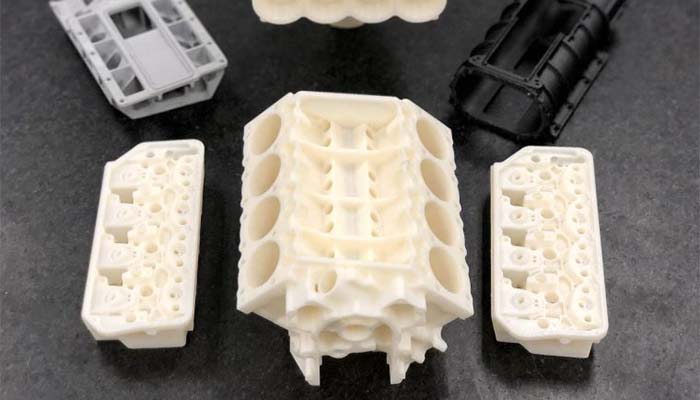

Chassis or weldment fixturing, prototype development, final design proof-of-concept, and finished ultralight usable components will all benefit from the 3D technology. With the use of Stratasys’ 3D printers – already fully integrated into the team’s fabrication shop – all of the above should be achievable. “Competitive motorsports demand technology that can not only handle the design complexity of these environments, but also rapidly create prototypes and parts to withstand the high-performance requirements of racing”, explained Pat Carey, Senior Vice President at Stratasys.

Don Schumacher Racing is leveraging both the Stratasys Fortus 450mc and F370 3D Printers to accelerate prototype development, proof-of-concept and finished ultralight usable components | Source: Stratasys

The manufacturer of FDM and PolyJet 3D printers has been involved in a wide range of industries from aerospace, automotive, healthcare, consumer products and education. Back in January, Stratasys was collaborating with Angel Trains to integrate 3D printed parts in the railway sector by offering cheaper, faster, lighter and more efficient parts. In regards to this most recent collaboration, Pat Carey adds, “Don Schumacher Racing is a great example of the power of additive manufacturing at work – and we’re excited to work alongside the team and tackle the most extreme challenges across their production environment.”

What do you think of this collaboration? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!