DoD Awards $4.5 Million to Ceramics 3D Printing

The United States pioneered the use of additive manufacturing in the defense sector, and their Department of Defense (DoD) continues to fund additive manufacturing research to this day. Through the Office of Naval Research (ORN), the DoD awarded a $4.5 million Multidisciplinary University Research Initiative grant to researchers based at Penn State to study the optimization of ceramic fabrication for 3D printing.

High-performance ceramics are commonly used in the aerospace and defense industries because they can withstand thousands of degrees Celsius and rapid temperature changes without degradation. However, the material is difficult to produce, and even more difficult to 3D print. To alleviate this issue, the DoD awarded this $4.5 million grant to researchers so they could study the use of laser processing to produce high-performance ceramics at lower temperatures. The scientists hope to enable ceramic fabrication through 3D printing by producing this material at lower temperatures.

Robert Hickey, one of the leaders of the research team (photo credits: Matthew Carroll)

Robert Hickey, associate professor of materials science and engineering at Penn State and one of the team leaders, and Michael Hickner, a professor at Michigan State University, are leading the team. Their project is titled “Photochemical and Photothermal Additive Manufacturing of Preceramic Polymers,” and according to an article from Penn State, it “seeks to create a one-step process to produce ultra-high-temperature ceramic materials without bulk heating.”

Hickey explained the main obstacle in creating ceramics. “The big problem currently in forming ceramics is the high temperatures and high energy required,” he said. “That has been a detriment, especially for 3D printing, which is currently very hard to do precisely with these materials.”

Currently, creating ceramics involves taking polymer precursor material and heating it to high temperatures in bulk. This heating converts the polymer precursors into ceramics, but as much as 50 percent of the precursor material can be lost in the process. Additionally, the heating technique can change the geometry of the ceramic part. To modify this procedure, the Penn State team is studying how light can convert polymer precursor models into the final ceramic product instead.

The solution, the scientists believe, may lie in high-intensity lasers. These lasers could trigger chemical reactions in the precursor materials so that they could rapidly densify into hardened ceramic materials without bulk heating. Heating material with light allows for faster processing than traditional methods, which would enable rapid 3D-printing.

“There’s a major need to try to reduce the energy necessary to convert or make these ceramics and to prevent major geometry changes after printing and processing,” Hickey said. “So, really, we are looking at how to convert polymers into ceramics using light with the ultimate goal of 3D printing high-performance ceramics.”

How Will Their Research Further Ceramics 3D Printing?

According to the same article from Penn State, the scientists said “The project will involve synthesizing novel precursors, exploring different ways to promote light-based ceramic conversion, gaining computational insights into the reaction conversion pathways and feeding the insights back to precursor design and synthesis.” These findings would be useful for the production of advanced hypersonic vehicles that must perform at ultra-high temperatures.

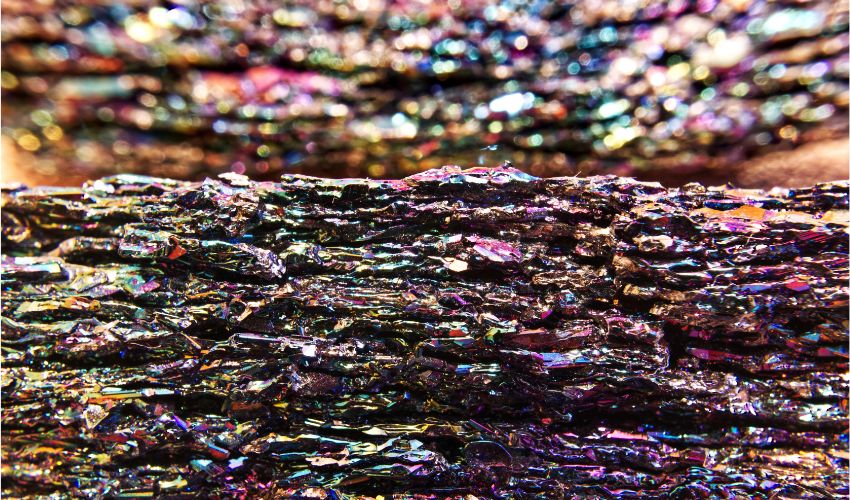

“This program will open new avenues to additive manufacturing ceramic materials across a number of high-temperature metal carbides, such as tungsten carbide, and silicon-based ceramics, such as silicon carbide and silicon nitride,” said Adri van Duin, Penn State distinguished professor of mechanical engineering and a co-PI. “Additionally, new computational capability will be built to predict high-energy reaction intermediates, which will be used to design new precursors and processing regimes.” To learn more about the project, read the article from Penn State here.

What do you think of Penn State team’s idea to use light to create ceramics for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo: Silicon carbide, one of the materials that will be worked with, in its mineral form.