Can DLP Be Used in the Creation of Microfluidic Chips?

Medical applications in 3D printing are vast and growing larger by the day. One that is increasingly important, but perhaps less discussed, centers on microfluidics. Microfluidic devices (microfluidic chips) have emerged over the past 30 years and have been rapidly integrated into many different biomedical applications including but not limited to cancer research, drug screening, drug delivery and molecular diagnostics. And, additive manufacturing is also being used to produce the important devices, with a recent research paper from the Faculty of Pharmacy at Aristotle University of Thessaloniki, Greece showing how DLP could be used for their fabrication.

As mentioned, microfluidic devices have been gaining in popularity in recent years. But what exactly are these? Well, microfluidics refers to the manipulation of fluids at a microscopic scale. It allows for fast responses, minimal sample consumption and high throughput. Meanwhile, microfluidic devices, namely microfluidic chips, are a set of micro-channels that have been etched or molded into a material. Traditionally, devices in microfluidics are made of glass, silicon and polydimethylsiloxane (PDMS). Yet increasingly they are also being made with AM.

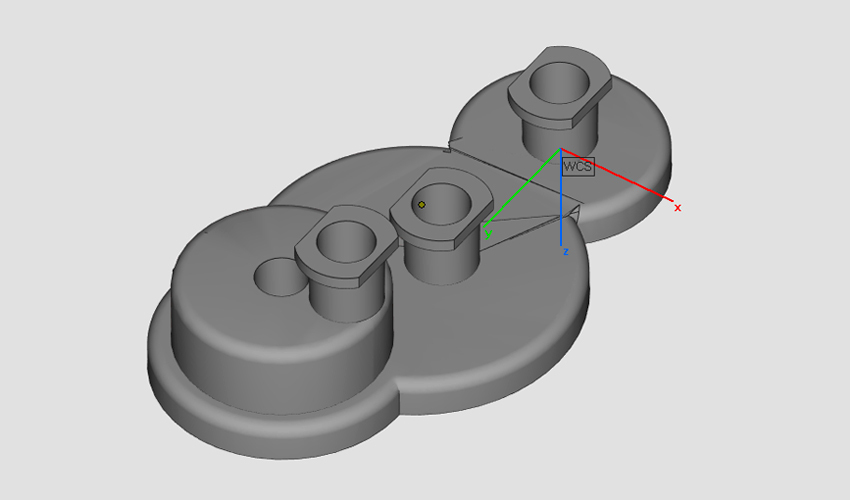

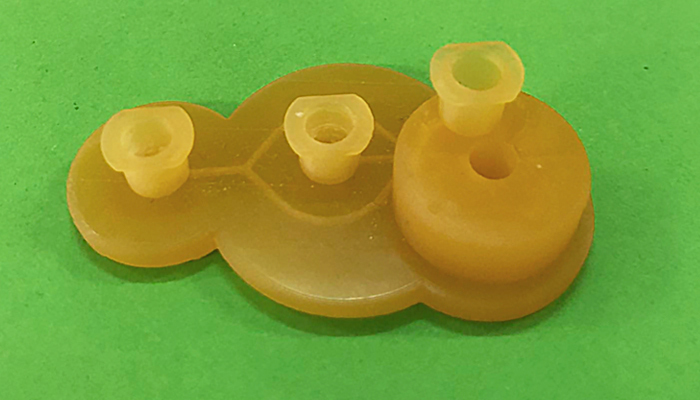

The microfluidic device made by the researchers

Previously, only Stereolithography (SLA) and Two Photo Polymerization (2PP) have been used thanks to their precision and ability to produce parts with small dimensions. But those are no longer the only options. In the study “Fabrication of a microfluidic device using Digital Light Processing (DLP) 3D printing,” Eleftherios Andriotis, Paraskevi Kyriaki Monou and Dimitrios Fatouros have outlined how to fabricate a microfluidic device with Digital Light Processing (DLP). The researchers were able to accomplish this task with the help of Lino3D, a well-known 3D printing lab based in Greece.

Making the Microfluidic Chips

For those well-versed in 3D printing, you will know that DLP is one of the AM processes using photopolymerization. However, in contrast to SLA, which uses a laser to cure point by point, or LCD, DLP uses a video projector to quickly and accurately cure resins layer by layer. EnvisionTEC, now ETEC, were the originators of the technology and they are also who the researchers turned to for the creation of their microfluidic devices.

Specifically, they decided to use E-RigidForm Amber resin as well as an ETEC D4K 3D printer in order to create the microfluidic chip. The polyurethane-like resin was useful because it can print strong, hard and stiff end-use parts. Beyond that, it has good heat deflection and most importantly is water-resistant which is critical, of course, when working with fluids.

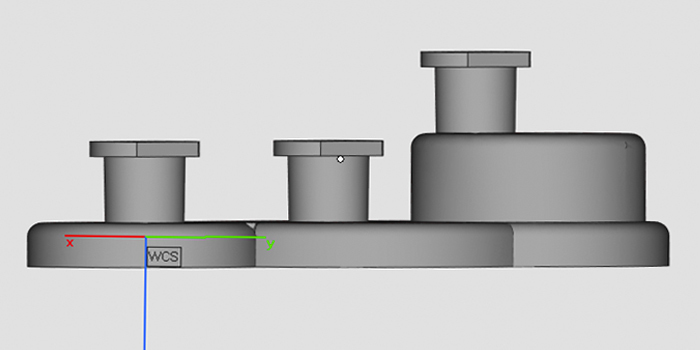

The CAD file showing the design of the microfluidic chip

Additionally, the D4K is known for desktop production of high-resolution parts in a variety of sectors including jewelry and dentistry. Not only does it have the fastest speed for a standard DLP printer, according to ETEC, but it is able to deliver extremely accurate parts with very fine detail. This of course was crucial since microfluidic devices are created on a microscopic scale and involve extremely detailed channels which must be perfectly made for their purpose.

Then to create the chip itself, the researchers designed it first in AutoCAD 2019 before exporting it as an STL. In the design, the channel width was set at 700 µm with Luer locks attached to the inlets and outlets to facilitate the tubing connection. While printing, the layer height was set to 1 µm.

Though the printing itself was successful, afterwards the researchers needed to find a way to remove any liquid resin blocking the inlets and outlets. Washing with isopropyl alcohol (99.9%) was unsuccessful so they turned instead to an automated resin removal machine, the DEMI 400 from PostProcess Technologies. This allowed the researchers to clean the printed parts while maintaining the quality. The final result was a success, hopefully paving the way for even more applications using these technologies. You can learn more about Lino3D who were instrumental in helping creating these chips HERE.

What do you think of the use of DLP to make microfluidic chips? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Lino3D