Digital Twins in 3D Printing: All You Need to Know

Have you heard of digital twins? The idea was first developed in the 1960s as a way to create a living model of the Apollo mission in order to help evaluate its failure through a physical model of the vehicle with digital components. The concept has understandably grown since then, but the core stays the same. In essence, a digital twin is a virtual model that has been designed specifically to accurately reflect a physical object. Not only that, but according to IBM, a digital twin could be considered as “a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.” Though it is often confused with just modeling, digital twins go beyond that. The use of algorithms and mathematical workings in digital twins are an important part of allowing users to predict behavior of the parts, such as those made with 3D printing.

They have found their place in a variety of applications from manufacturing to medical to even interior design. Furthermore, they are increasingly being used in additive manufacturing. Though that is perhaps unsurprising when considering the fact that the digital twin market was already estimated to be worth $6.9B in 2022 and grow to about $73.5B by 2027 according to Markets and Markets. But why exactly would you use digital twins in 3D printing? What do you need to know before doing so? We took a closer look.

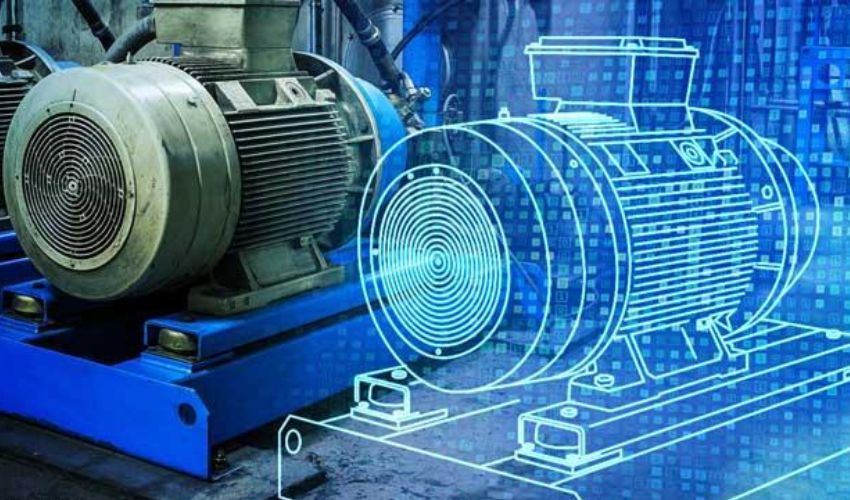

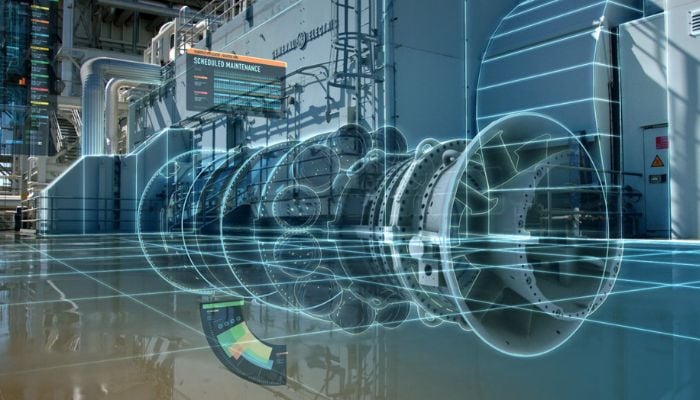

Digital twins are increasingly used as part of Industry 4.0 (photo credits: GE)

Using Digital Twins in 3D Printing

Digital twins and additive manufacturing are both considered to play a key role in Industry 4.0. However, it has only been in recent years that the two have started to be combined. Still it is important to note that many different studies have found that 3D printing in general is well-suited to the use of digital twins. Why? Because by its very nature, additive manufacturing is digital. From online design to software for slicing to programs that monitor throughout the printing process, automation and AI have already found a home in AM for this very reason. Digital twins would just be another tool to add.

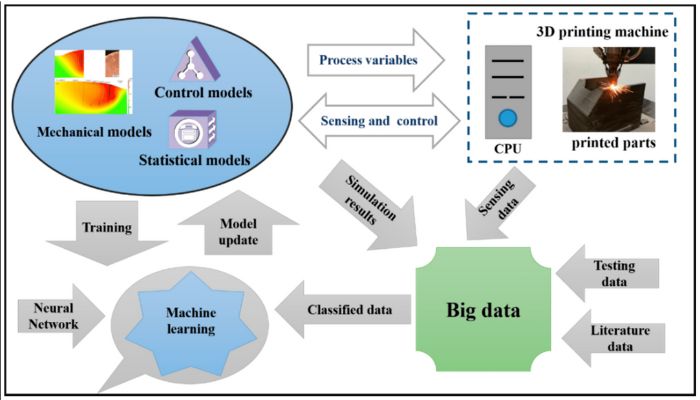

But how do you use them? Well, let’s first consider the process of integrating digital twins in 3D printing. As mentioned before, a digital twin starts as a 3D model. This can be made through CAD or generative design software. Additionally, 3D scanning is increasingly also being used as it creates a perfect model of the part in question. Beyond the initial design, there are already a number of software programs available on the market that are designed specifically to work with digital twins including for 3D printing. Take for example those from Siemens, Simio or Netfabb. This eases integration, thus further propagating usage in general in AM. Not to mention, it is easy to see how it could be used for applications such as reverse engineering of spare parts thanks to its ability to truly recreate products.

Finally, there are a few different forms that digital twins can take, so that also must be considered. According to one report, digital twins can be divided into four categories for additive manufacturing; process digital twins; equipment digital twins; facility digital twins; and product digital twins. As their name suggests, they target different areas in a manufacturing process. Process digital twins can be used to replicate a digital version of the 3D printing process for design, production and maintenance. Similarly, equipment digital twins can replicate printers, providing important information for maintenance work. Facility digital twins are a mix of the first two but on a larger scale, taking the entire factory floor into account. Last but not least, and what we will discuss foremost in this guide, product digital twins are representations of a product and part enabling it to be optimized, tested, designed and analyzed to predict performance.

A representation of how digital twins work with 3D printing (photo credits: Zhang, Li, Xiaoqi Chen, Wei Zhou, Taobo Cheng, Lijia Chen, Zhen Guo, Bing Han and Longxing Lu)

Why Integrate Digital Twins Into AM?

There are quite a lot of benefits as well for the combination of digital twins with 3D printing. Notably when it comes to quality control of parts. Though AM has changed a lot from its origins as rapid prototyping, with more and more end-use parts coming onto the market, quality control remains a concern. Indeed, due to its very nature, AM often requires extensive testing to ensure the correct parameters to prevent print failures. But this is in direct contrast to two of AM’s biggest advantages, namely cost and material reduction.

Thankfully, through the use of digital twins, this can be addressed. Digital twins allow users to directly assess parameters thanks to the continual stream of data due to the feedback. This in turn allows for optimization of said parameters without the need for physical testing. Moreover, with digital twins, real time monitoring throughout the 3D printing process is possible allowing for even greater accuracy for the final prints. This in terms makes quality control for AM more reliable. This is especially important when it comes to the more industrial processes, including for metal AM through methods like laser powder bed process as it could also increase consistency.

In addition, as covered above, digital twins are not just used for single parts. In fact, they can be made for an entire factory floor. This would make industrialization especially more feasible for additive manufacturing as 3D printer farms could be optimized not just on an individual level, but on the entire floor for more effective production.

That is not to say there are not still challenges. The actual definition and development of a digital twin is still quite difficult, not the least because as many scholars have noted the framework itself if not well-understood. However, the more that digital twins and 3D printing are used together, the more quickly that obstacle will be overcome. And that is already happening on a larger scale, especially with the increased use of AI and more sophisticated tools for machine learning. It will certainly be interesting to see how digital twins and 3D printing are used together in the future and how it will change.

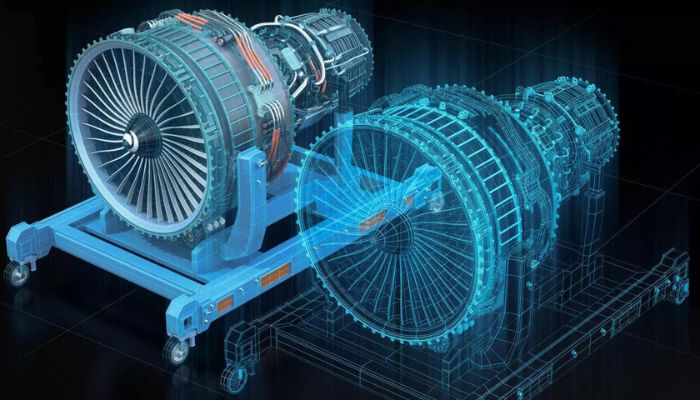

We can probably expect to see an increased usage of digital twins in 3D printing especially for parts like turbines (photo credits: Konica Minolta)

What do you think about the use of digital twins in 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Norlà Corporation