Developing 3D printing filament from recycled plastics

In Denmark, a professor at the University of Aarhus, Mogens Hinge, is conducting a research project to recycle plastic waste into a standardised 3D printing filament for the entire market. Called “Development of filament for 3D printing based on recycled plastics”, the project has already received €84,000 in funding from the Danish Innovation Fund and is led by the Danish plastics recycling company, Aage Vestergaard Larsen A/S. In this way, the professor hopes to offer all users a consistent filament quality, without variation from one spool to another. It may also give them more incentive to move towards a circular economy and facilitate the process of manufacturing filaments from recycled materials.

The engineering professor’s approach is based on a simple observation: there is too much difference between two batches of filaments, whether the brand is well known on the market or not. According to him, the quality is not always the same when changing spools, which can increase the fail rate, repeat printing, lengthen the post-processing time, etc. He claims that these differences are due to “the careless use of plastic for the 3D printing filament, and the fact that the components are not dimensioned according to the material, as is the case in the plastics industry“.It would therefore be beneficial for the industry to standardize the manufacturing process for thermoplastics, a project that seems very ambitious at first sight. Perhaps this is why Professor Mogens Hinge has decided to focus initially on recycled materials.

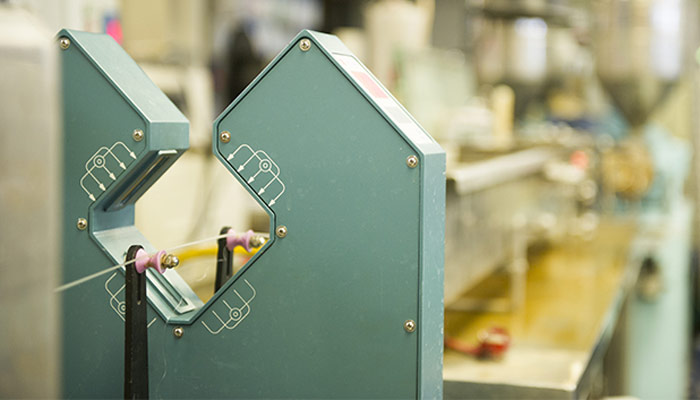

The quality of a filament can vary from one batch to another depending on the Danish teacher (photo credits: Real Filament)

Mogens Hinge is working hand in hand with Denmark’s largest plastic recycling company, Aage Vestergaard Larsen A/S. Gitte Buk Larsen, head of business development and marketing, explains the reasons for the collaboration: “Firstly, it has not yet been possible to produce a filament from 100% recycled plastic. Secondly, no one has yet deciphered the production code for the filament on the basis of a data sheet to ensure uniform quality. And thirdly, there are currently no filament producers in Denmark.” Mogens Hinge would therefore have to provide quality documentation in order to produce filaments from recycled materials, the beginning of a manufacturing standard that would finally allow every user to benefit from consistent quality from spool to spool. This would also include printing characteristics such as the melting temperature of the filament or its glass temperature.

Gitte Buk Larsen continues: “If the project is successful, it will revolutionize the material consumption of 3D printers, which today are largely made of new plastics. The aim is to be able to use plastic waste to create new high-quality filaments. This will have a significant impact on the environment and the climate in the long term.” As the group has a wide range of different quality polymers, it will be easier for project stakeholders to test several materials and develop a standardized 3D printing filament.

Mogens and Gitte choose different plastics (photo credits: Aage Vestergaard Larsen A/S)

This Danish initiative joins the many projects that rely on a circular economy by proposing to give a second life to our plastic waste: the young American student from Project PLA a few months back is a perfect example. One thing is certain: 3D printing can do our planet a world of good! What do you think of this project? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!