3D Printing Breakthrough Allows for the Detection of Milk Fever at an Early Stage

Milk fever is a widespread problem in agriculture that can have considerable economic and health consequences for cows and farms. One of the most common metabolic diseases in dairy cattle, in one study, milk fever was estimated to affect 50% of mature dairy cows and 25% of first-calf heifers. The disease occurs in lactating cows and leads to a reduction in the calcium level in the cows’ blood, which impairs vital functions such as muscle and nerve activity. Furthermore, it also reduces milk production, which can cause economic losses of up to $290 per cow or around $8000 for a Dairy Farm with 100 cows.

Until now, it has been difficult for farmers to diagnose milk fever, as typical symptoms are often not recognizable. This is now set to change, however, as a team of scientists at Virginia Tech has used additive manufacturing to develop a sensor that can detect milk fever in just ten seconds – a sustainable solution for agriculture and animal health.

The task of the sensor is to measure the concentration of calcium and phosphate in milk samples from cows. It was manufactured using polymer resin 3D printing technology, which was chosen for its cost-effectiveness and flexibility. The production process included layer-by-layer printing with UV curing to form microscopic surface structures and a gold coating using e-beam evaporation. The microscopically corrugated surface enables high sensitivity, and the sensor structure comprises a total of three electrodes, two of which serve as working electrodes.

These were coated with ion-selective membranes for calcium and phosphate. It is particularly important that the sensor can detect the ion concentration in the attomolar range, i.e. 138 aM for calcium. This makes it possible to detect even minor signs of milk fever before more severe symptoms can occur.

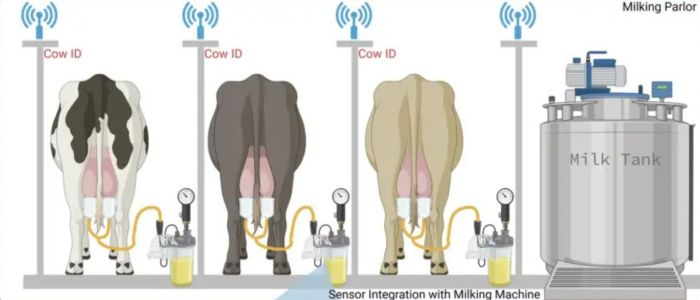

The 3D-printed sensor can be easily integrated into milking systems and offers fast and accurate analysis of calcium and phosphate levels in milk samples to detect milk fever at an early stage (photo credits: School of Animal Sciences, Virginia Tech, Blacksburg, USA)

The 3D-printed sensor has many advantages, most notably its price, as traditional diagnostic solutions are often expensive and complicated to use. The new sensor, on the other hand, can be produced in just two hours with minimal use of resources, and no specialist knowledge is required to use it.

It also contributes to sustainable animal husbandry as it promotes cow health monitoring, enabling quick and accurate diagnoses on the spot. Moreover, economic losses can be minimized and the sensor also offers the possibility of expansion, for example to measure different biomarkers in milk samples to detect other animal diseases. Find out more about the project HERE.

What do you think of the use of 3D printing in the production of the sensor? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.