Detecting Defects in Metal 3D Printing Using Sound

At the École Polytechnique Fédérale de Lausanne (EPFL), a team of scientists has been studhing the issue of defects in metal 3D printing, particularly when using a laser process. Their aim is to develop a method based on the analysis of 3D printer sounds, in order to anticipate printing errors and thus enable better results. They therefore studied the sounds emitted by a machine during a flawless process and those of a 3D printer that showed faults during printing. In collaboration with the Paul Scherrer Institute (PSI) and the Swiss Federal Laboratories for Materials Science and Technology (Empa), EPFL placed a microphone in the printing chamber to detect shifts in the acoustic signal as the metal powder changed state.

The detection of printing errors is not new, and numerous projects have been developed in recent years to guarantee reliable and repeatable results. This process generally relies on algorithms capable of drawing conclusions from situations that are already known. As a result, they are often imperfect and require extensive testing. By relying on a sound-based technique, the EPFL scientists aim to overcome this constraint.

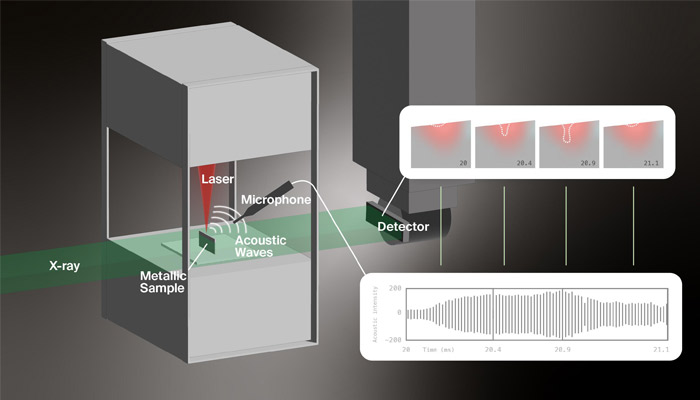

Graphic representation of the experimental device for monitoring printing defects – 2023 EPFL / Titouan Veuillet – CC-BY-SA 4.0

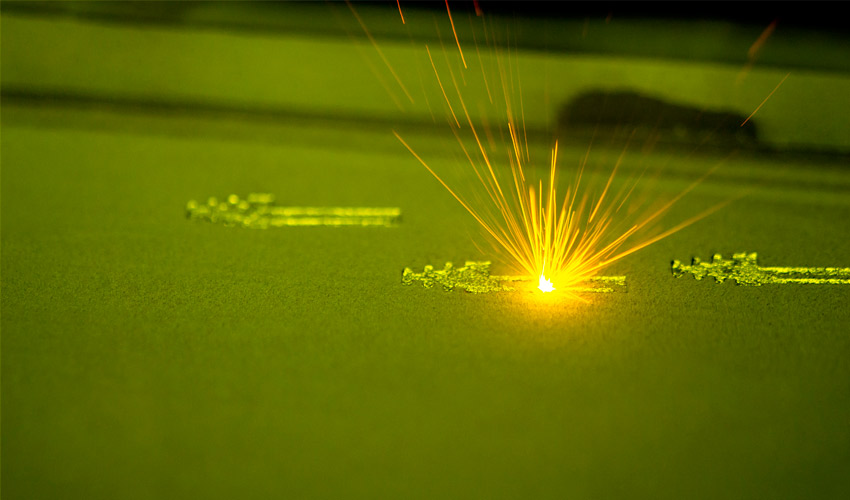

In laser powder bed fusion, a thin layer of metal powder is heated to form the desired object, layer by layer. The material passes through different phases – solid, liquid and gaseous – creating a molten bath. The EPFL explains: “Occasionally, due to variables such as the laser’s angle or the presence of specific geometrical attributes of the powder or of the part, the process might falter. These instances, termed “inter-regime instabilities”, can sometimes prompt shifts between two melting methods, known as “conduction” and “keyhole” regimes.”

The teams use X-ray images to measure this melt pool (in width and depth) and have developed a method that enables them to see the changes in the metal when it is liquid. Thanks to a microphone installed in the printing chamber, they are then able to record the sounds produced during transitions between regimes and spot any shifts. If they exist, a defect has been detected. Lead researcher Milad Hamidi Nasab adds, “The synergy of synchrotron X-ray imaging with acoustic recording provides real-time insight into the LPBF process, facilitating the detection of defects that could jeopardize product integrity.“

The researchers are only at the beginning of their experiments, and are confident about the future of this solution. However, what is certain, is that it should make it possible to design parts with greater reliability and repeatability, a key point for many manufacturers today. You can find the official press release HERE.

What do you think of this method of detecting defects in metal 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.