Desktop Metal launches Fiber 3D printer for continuous fiber 3D printing

You all know Desktop Metal for its metal 3D printers, designed to fit into an office environment with the Studio System and to also enable mass manufacture with the Production System. The U.S. manufacturer has announced the launch of a new machine that has nothing to do with metal. In fact, Fiber is a desktop 3D printer capable of creating high-resolution parts with industrial-grade continuous fiber composites. It uses a new process called micro Automated Fiber Placement (μAFP) technology, a technique designed specifically for composite materials. This new technology will enable users to produce solid parts in a wide range of materials at a lower cost compared to other traditional AFP processes.

Desktop Metal has raised $400 million in the last four years and continues to conquer the additive manufacturing market by turning to composite 3D printing, which are increasingly interesting for the sector because of their strength-to-weight ratio. In general, continuous fiber 3D printing is growing in the industry, companies such as 9T Labs, Anisoprint and moi composites are perfect examples of this. Desktop Metal has joined the race with its Fiber solution.

Desktop Metal’s Fiber 3D printer

Fiber, between FFF printing and AFP technology

Fiber is the first desktop printer that combines fused filament fabrication (FFF) with AFP technology. It uses a robotic tool changer, capable of storing up to 4 types of tools, including additional FFF print heads for different materials. According to Desktop Metal, the new machine can produce parts with materials twice as strong as steel, yet five times lighter. At the moment, two printer models are available via a subscription service with a minimum three-year commitment plan.

The Fiber HT model, available from $5,495 per year, has been designed to produce parts with continuous composites with a porosity of less than 1% and continuous fibre loading of up to 60% with an advanced matrix, including PEEK and PEKK. The structures created can withstand temperatures reaching up to 250°C, and comply with ESD standards. The other machine, the Fiber LT, allows the printing of continuous fibres with a porosity of less than 5% with PA6 thermoplastics. It also complies with ESD standards and will be available from $3,495 per year. Both machines offer a printing volume of 310 x 240 x 270 mm.

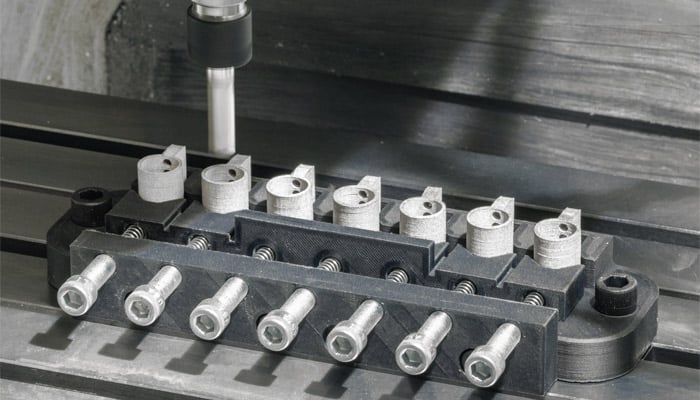

3D printed mounting system using the Fiber solution | Credits: Desktop Metal

Looking at compatible materials, Desktop Metal announces a wide range of choice, including high-performance thermoplastics. These include ESD compliant carbon fibre reinforced nylon (PA6), other glass-fibre reinforced nylon and carbon fibre reinforced PEEK and PEKK filaments. The manufacturer claims that the resulting parts are up to 60 times stiffer and 75 times stronger than ABS plastic parts, allowing a wide range of applications.

Fiber 3D printer, what are the applications?

As you will have understood, the Fiber 3D printer will be particularly appreciated by industries looking for high-strength yet lightweight parts. We can name the aerospace and automotive industries, for which heat resistance and lightness are interesting properties. Desktop Metal specifies that composite parts can be useful from the prototyping stage but also for the creation of tools. The manufacturer targets many industrial sectors such as the automotive, consumer electronics, sports, medical, education and marine sectors. David Hauber, Technical Director of Trelleborg Sealing Solutions Albany, Inc, explains: “Despite all the advantages, polymer-based AM has been lacking in the strength needed for high performance applications, specifically a technology that bridges the gap between existing AM technology and automated fiber placement of high-performance composites as used in industry. After more than three decades of development, AM has finally reached a tipping point.”

The new machine is expected to be particularly popular in the automotive sector | Credits: Desktop Metal

What do you think of Desktop Metal’s new desktop Fiber 3D printer? You can leave a comment in the section below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, to receive all the latest news in 3D printing straight to your inbox!

A perfect compact desktop friendly, noise-free, heavy-duty metal 3d-printer is “Desktop Metal”. I mainly preferred its fused filament fabrication with automated fiber placement and desktop metal gives us a huge range of choice including high-performance thermoplastics. It accomplished the hardest details smoothly. Have a look at my facebook page & tryout frequent materials.

Chopped carbon fiber-filled thermoplastics are printed through a standard FFF (FDM) printer, and are comprised of a thermoplastic (PLA, ABS, or Nylon) reinforced with tiny chopped strands are carbon fiber.

In this era, Desktop Metal is a company that plans and creates a sphere for the global market. It has created an end number of contriving materials which is helping to run the 3d printing business across the globe. It had launched Fiber 3d printer which will enable high manufacture in several areas and earn revenue. Through its advanced technology, it is establishing a milestone in the fields of

3d in the global world and increasing demand across the globe.

I have been using Ricoh’s printer for the last 3 years, now it doesn’t work properly so I am looking to buy another one 3D and multifunctional printer for my office. Can anyone suggest how is “Fiber 3D Printer”?

The 3D printer is being used in various fields & now Desktop metal launches fiber 3D printer for continuous fiber 3D printing. This article has all the necessary information about this printer & interested people can have a read.

Combining fused filament fabrication (FFF) with AFP technology is a game-changer. It is also at a very affordable price. I like it.

The fiber 3D printer is an innovative technology and very much demanding for its high strength and lightweight parts. So this is a great article to know more about this.

3D printers are mainly used in industries and in the medical fields. Now many 3D printers are available with innovative features and shapes. These are high-speed printers with modern features.

It’s superb technology & to start this technology in ?? will how much?????