DefeXtiles: using under-extrusion to create a new type of textile

At MIT, researchers and engineers often imagine creative projects and develop innovative products related to the world of 3D technologies. Recently, Jack Forman, one of the graduate students, developed a new type of textile by exploiting one of the common mistakes in 3D printing, under-extrusion. By controlling this defect, he designed DefeXtiles, a kind of tulle-like textile that he can model into complex shapes and geometries. He has thus designed an interactive lampshade, skirts, pieces of lace, a badminton shuttlecock, etc.

Under-extrusion is a common phenomenon in FDM 3D printing that occurs when there is not enough extruded filament. Voids are created between the different layers because they cannot be bonded properly. In the case of this young maker, under-extrusion is not a problem – it can be controlled and finally transformed into force. All he needed was a $250 desktop FDM 3D printer and standard materials. Forman says, “Unlike previous work, the fact that no custom software or hardware is needed — just a relatively cheap $250 printer, the most common type of printer used — really makes this technique accessible to millions of people.”

Image credits: MIT Media Lab

DefeXtiles, a material like no other

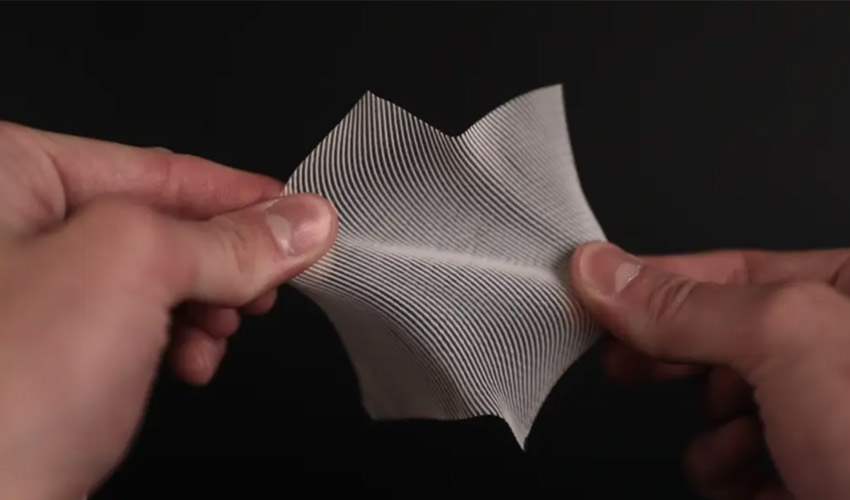

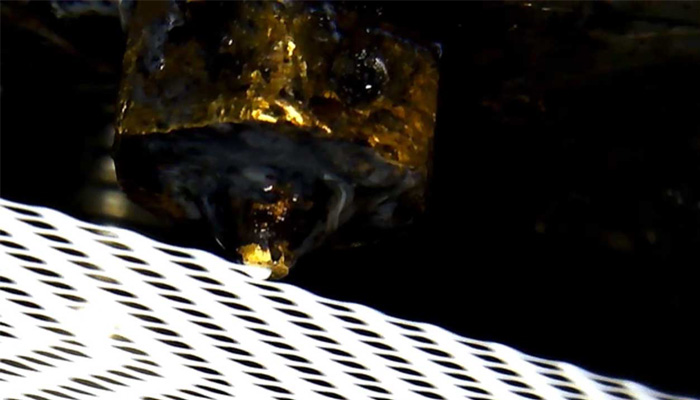

By mastering all its printing parameters, Forman developed an under-extrusion process called “glob-stretch”. How does it work? During the extrusion of the material, drops are formed in places, linked together by fine threads in contact with the layer below. He made all these drops align on a single column to create this tulle effect. Indeed, we can see very well this warp as if the piece had followed a weft, as if woven. Note that this piece is very flexible and stretchy. Jack adds, “Not only are these textiles thinner and faster to print than other approaches, but the complexity of demonstrated forms is also improved. With this approach we can print 3D dimensional shell forms with a normal 3D printer and no special slicer software“.

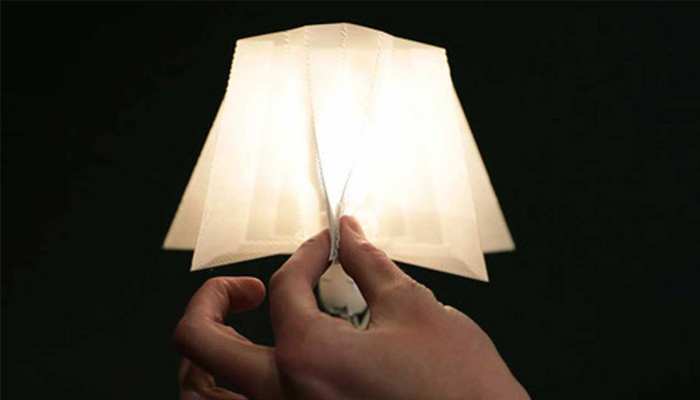

Jack says the textile can be sewn, de-pleated and heat-bonded. Other base materials could be added to the textile to obtain magnetic or optical properties. He is even considering the production of biodegradable textiles using algae, coffee grounds or wood. In terms of applications, Jack has made a few pieces including a lampshade with a conductive filament to light the lamp directly by touching its folds.

In the deformation-sensing lamp, the solid supports, textile lampshade, and sensing conductive pads were created as a single print. (Image credits: Jack Forman)

Professor Hiroshi Ishii who supervised this research project concludes: “We envision that the materials of the future will be dynamic and computational. We call it ‘Radical Atoms.’ DefeXtiles is an excellent example of Radical Atoms, a programmable matter that emulates the properties of existing materials and goes beyond. We can touch, feel, wear, and print them.”

What do you think about DefeXtiles, the new 3D printed quasi-textile? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!