Application of the Month: Customizing Police Vehicles With SLS 3D Printing

Police vehicles are not like other cars. Although they may look much like normal vehicles on the outside, apart from their lettering and sirens, they are very different on the inside. In fact, patrol cars are specially equipped to carry out security missions and respond to all kinds of situations. In general, the interior is adapted to include communication systems such as radios and computers, dashboard camera mounts and radar – even the trunk of each car is transformed. However, these modifications have to be tailored to the specific requirements of each police force, requiring a high degree of customization. This is where the work of companies such as MOSOLF Special Vehicles GmbH comes in. Better yet, the manufacturer has incorporated 3D printing into its developments to meet the requirements of police forces in Germany.

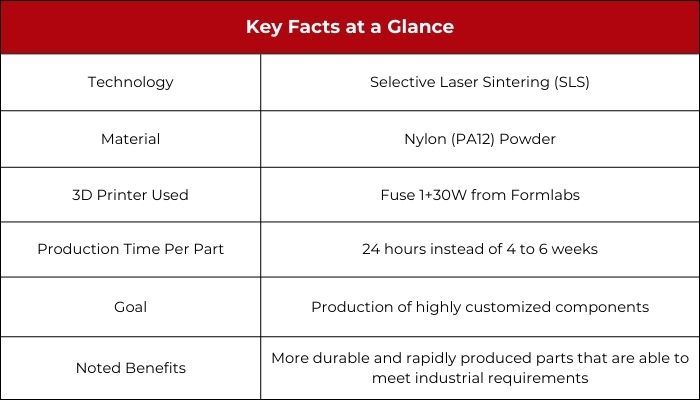

MOSOLF Special Vehicles GmbH is a Kippenheim-based company specializing in the conversion of special vehicles. These vehicles are used by German police forces, defense agencies and emergency services. Every year, the company modifies around 1,000 units, and supports its customers throughout the entire process, from vehicle design and production to the resale of the vehicles when they reach the end of their life. Today, we wanted to highlight the use of selective laser sintering (SLS) to transform the interiors of mass-produced police cars.

Customized radio stand (photo credits: Formlabs)

MOSOLF Works on Customization to Suit Each Police Vehicle

MOSOLF works with production vehicles, including cars, trucks and vans, tailoring them to the specific needs of each customer. Additive manufacturing has enabled it to meet the challenges associated with customization, particularly on new models that feature more detail and components, leaving less space to include the required communication or signage systems. It was the design flexibility of 3D printing that provided the solution to this challenge, enabling the creation of components that fit into every nook and cranny of the vehicle.

Each police force has different requirements in terms of ergonomics and equipment, which adds to the complexity of the customization work. MOSOLF manufactures vehicles for 17 police forces in Germany, each with its own specifications. However, thanks to 3D printing, the company is able to quickly adapt the models to these variations. This is essential, enabling it to meet the high levels of personalization demanded by each of its customers.

Trunk-mounted holder for emergency lamp (photo credits: Formlabs)

SLS 3D Printing as a Production Method

Selective laser sintering proved to be the ideal process for MOSOLF. Why? Well, SLS 3D printing offers an optimum combination of quality, precision and durability, enabling multiple components to be produced simultaneously at an efficient cost. Compared with FDM technology, previously used by MOSOLF, SLS has enabled it to increase its production capacity for the parts it needs and, above all, to achieve the industrial standards it demands.

Furthermore, traditional production methods for police cars are better suited to high volumes and standardized products. However, the German company’s customers only require small runs of parts, which is why 3D printing has become the ideal method for the rapid production of unique components.

One of the strengths of this technology is its ability to produce parts in a very short time. With SLS, MOSOLF can manufacture final parts in just 24 hours, compared with four to six weeks previously. The agility of their production encouraged them to adopt the technology. They now produce 80% of their parts using SLS technology, in particular via Formlabs’ Fuse 1+30W SLS 3D printer.

Housing for a lamp on the roof of a police vehicle (photo credits: Formlabs).

The material used is nylon, chosen for its high resistance to heat. PA12 powder ensures that parts retain their integrity even in adverse conditions, such as when vehicles are left in the sun during the summer.

In conclusion, Carsten Busam, Head of Project Planning at MOSOLF Special Vehicles GmbH, explained to Formlabs in an interview: “I estimate that every third police van [in Germany] now contains additively manufactured parts. At MOSOLF, we are now so far advanced with 3D printing that there is no vehicle that leaves our yard without an additively manufactured part in it. We now 3D print around 5,000 parts per year, but we are on an upward trend, which means that we have at least three parts in every vehicle if not more.”

What do you think about using SLS printing to customize law enforcement vehicles? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: MOSOLF Special Vehicles GmbH