Cura: All You Need to Know Before Getting Started

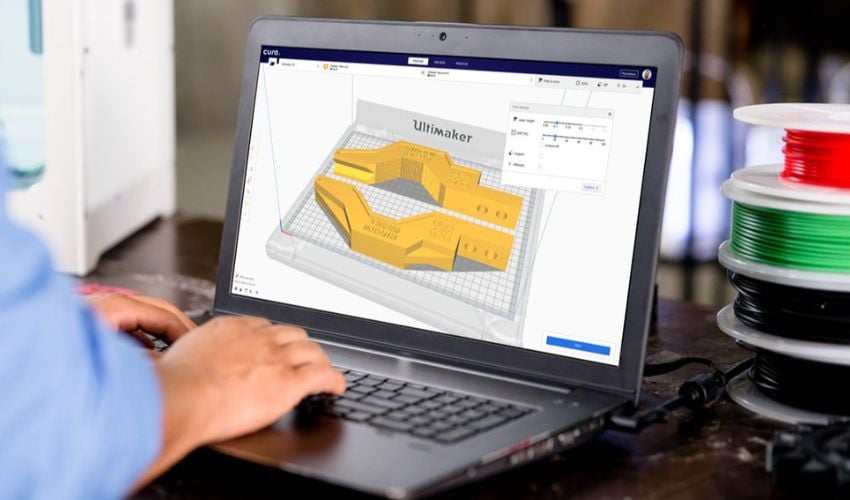

As many of you will know, in order to get a piece 3D printed, you need a slicing software, more commonly known as a slicer. The slicer converts the 3D model into a G-code file that will provide the 3D printer with all the necessary instructions for printing. Cura is a slicing software developed by David Braam in 2014 for this purpose – it was later acquired by Ultimaker. Now, this open-source software is probably the most widely used in the global additive manufacturing market. It is estimated to be used by more than one million users for more than two million printing jobs every week. But what exactly makes Cura so popular?

One of the main benefits of Cura is its ease of use, support for different file formats, and compatibility with many 3D printers. Supported file formats are STL, OBJ, X3D, and 3MF. Although Cura is part of the UltiMaker ecosystem, printers from other manufacturers can also use it. The software is not only 100% free of charge but is also available in 15 languages so that users worldwide can use it as easily as possible. Another feature that contributes to its popularity is the fact that it is compatible with the most common operating systems, Windows, Mac, and Linux. Note that Cura has been certified for Windows and macOS platforms, guaranteeing significant additional security.

How Does the Software Work?

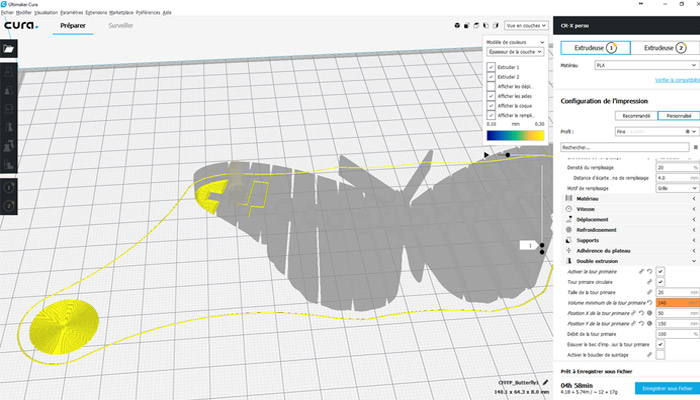

Cura has a simple interface that allows you to choose between two settings right from the start: the recommended mode and custom mode. The recommended setting is particularly suitable for achieving the best result in a few clicks – there is no need to make manual changes to the settings. However, the software is able to choose the optimal orientation of the part to save time for the user, but also the filling rate, the generation of optimized supports to minimize post-processing, layer thickness, etc. A good option when you’re just getting started!

The custom setting meanwhile allows the user to choose from more than 400 different setting options. In addition to the basic parameters such as the addition of support structures or the amount of filling required, other options can easily be added. Users can also get an idea of how Cura will cut out the model using the preview mode. Designed to be more ergonomic, it improves the user experience.

It is also possible to select the filament used as a profile before printing, so that the parameters are automatically changed accordingly. In fact, Cura presents numerous 3D printing profiles depending on the material chosen thanks to the Material Alliance Program: UltiMaker currently collaborates with more than 80 filament manufacturers around the world, has tested their materials and consequently offers pre-set profiles (more than 100). In its latest versions, for example, Cura has included parameters for FFF printing of metal filaments and the new UltiMaker PET CF composite material. By watching this video you can get an idea of how to use Cura, profiles and some of the available settings:

The Complete Cura Ecosystem

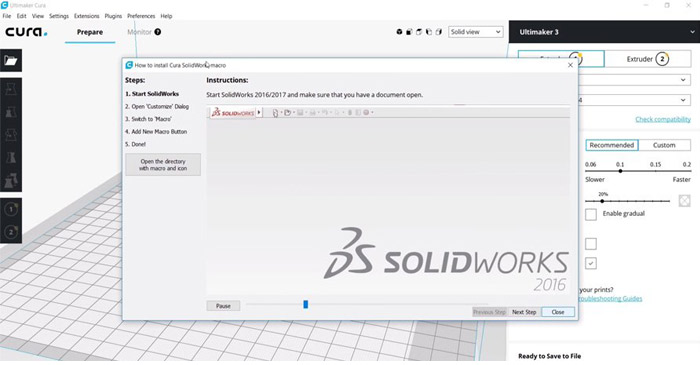

Being open-source and widely used around the world, Cura is constantly evolving. Users can access Cura’s cloud which allows them to send printing instructions directly to printers without having to use traditional storage media such as a USB stick. Users can also access their projects anywhere, all they need is a free account. Note that “Professional” and “Excellence” profiles are also available, allowing access to additional features. For example, via these two profiles, the user can now import their CAD files into Cura, simplifying the work of preparing the model.

Via Cura Connect, printing can be sent to several printers at the same time, which then work simultaneously. The tool allows you to plan and manage different print jobs on several Ultimaker 3D printers also. The interface offers a follow-up of the current print jobs, possible maintenance operations, etc.

The Cura Cloud will also give you access to a number of plug-ins. The most widely used is probably the one that allows you to push CAD data directly into the slicer from software such as SOLIDWORKS, AutoCAD, or Siemens NX. No need to change the formats, everything is integrated into one simple-to-use tool.

Cura Version 5.4

One significant benefit of the software is that Cura is constantly updated. The most recent version in 2023 is version 5.4 which has a some improvements compared to the previous versions. In particular, in addition to fixing several bugs, UltiMaker Cura 5.4 makes it easier to remove frames and supports from printed parts. Additionally, as mentioned, UltiMaker S series users can count on printing profiles for the new UltiMaker PET-CF composite material.

Finally, we remind you that today there is a large community of active users that allows you to share best practices and recommendations on the use of Cura. The forum is growing every day and can significantly improve the user experience. You can download the software HERE.

Are you using Cura? Do you have more questions about using Cura for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

I use DesignCAD for my 3D modeling. It can export in the following formats:

AutoCAD DWG, DXF, IGES, RIB, VRML, WordPerfect WPG, Windows Metafile, HPGL Plot, Adobe PDF.

Can I use it with CURA?

I need to know before I spend a large sum of money for a 3D printer ($400) is a large sum of money to me!).

I’ll anxiously await your reply.

Mark

Cura is a free open source software. Download it and and see what formats work. There are also free online file converters. You don’t need a printer for this part. I export using .stl files to Cura. Cura slices it to gcode, works fine on my $200 8 year old printer. When you start out 3d printing use PLA, as ABS is difficult to get the hang of.

I plan on creating sliced file on a thumb drive and then load it on to my makerbot printer. Is this possible? what I downloaded is looking for a printer on some kind of network.