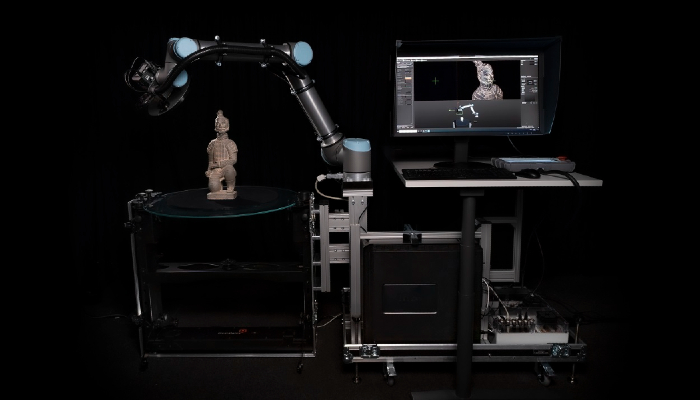

CultArm3D, an Automated Robotic Arm That Can Scan Cultural Objects in 3D

Fraunhofer Institute for Computer Graphics (Fraunhofer IGD for short), the leading world’s leading organization for application-oriented research, has developed a mobile 3D scanner called CultArm3D that can produce precise 3D models of exhibits of various sizes at the touch of a button. The product – as the name suggests – is to be used primarily in museums for the digitization of cultural assets. This project was successfully implemented in collaboration with the Danish camera manufacturer Phase One. Digitization of cultural assets is increasingly happening in museums and cultural institutions around the World as a way to allow people to visit with these important artifacts without physically being there. This has become increasingly important as COVID-19 has prevented people from traveling and gathering in public spaces. This advancement will allow museums to continue taking the steps forward into the digitial world, thanks to 3D scanning.

Bildnachweis: Fraunhofer

The head of department at Fraunhofer IGD, Pedro Santos, and his team have been working on the topic of large-scale 3D scanning technologies and digitization of cultural assets for many years. Mr. Santos himself explains why research in this area is so important: “3D models are tremendously important for research and can help improve our understanding of objects and their origins as well as analyze their attributes. They also serve as the basis for visualization in virtual and augmented reality, and when using 3D printing to create true-color physical replicas.” In addition, scientists can examine and compare 3D-printed cultural artifacts at will without living in fear of damaging the original – because original exhibits are often old, fragile and fragile. For this reason, the CultArm3D placed special emphasis on safety precautions to protect the scan objects. For example, the joints of the scan arm immediately lock into place in the event of a power failure. Other features that the 3D scanner also had to meet were: Results of the highest quality and an easy-to-use system.

CultArm3D features

The CultArm3D is equipped with a Phase One iXG 100 megapixel camera and Fraunhofer IGD’s autonomous scanning algorithms and complemented by specially designed ring lights for optimal illumination. This enables autonomous scanning of objects from all angles and high-quality detailed 3D rendering in the shortest possible time. Challenging during development was the fact that no two objects are alike, with objects having challenging surface geometries, such as shiny or reflective objects made of gold and bronze with complex undercuts, being particularly demanding. However, it managed to overcome the challenge, and that even eliminates the need to use matting spray to capture geometry on reflective surfaces. In addition, the use of the CultArm3D minimizes (or eliminates) manual post-processing of 3D models for complex object geometries.

Operation of the scan arm should be straightforward and can be performed independently by museum staff. During initial setup, integrated software guides the user through a short calibration process that only needs to be performed once. The cultural objects are positioned in the center of the turntable provided and, at the touch of a button, the scanning process starts. The user of the machine can now relax and watch the process: First, a quick pre-scan is performed to get an initial basic understanding of the size and shape of the individual object. Then, dynamic view planning during the scanning process ensures that all details of the object visible to the sensor are captured, with the minimum number of images, in optimal sharpness and true color. Dynamic view planning continues its work until the quality targets defined by the user in terms of minimum coverage and resolution are achieved. The completed 3D model can then be exhibited in various forms: as a high-resolution video in 2D or 3D, as a 3D web model, for virtual and augmented reality presentations, or as a print file for a 3D printer.

In fact, the scan arm is already in use at several museums and archives – not least because of its light weight, which makes it easy to transport. The resulting evaluations from the field provide the developers with valuable pointers for improvements. A sales channel via Phase One is then planned from 2022. Until then, museums can contact Fraunhofer IGD directly if they are interested in cooperation. You can find out more HERE.

What do you think of the CultArm3D? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!