Creaform’s 3D Scanning and Software Solutions for Reverse Engineering in Additive Manufacturing

Many industries have recognized the potential of 3D printing for efficient and sustainable production. Additive manufacturing allows individual parts or small batches to be produced relatively inexpensively, on demand and on site, guaranteeing a ready supply of spare parts, among other benefits. However, every 3D-printed part is based on a 3D model and the process of obtaining this can be bumpy and time-consuming. Thankfully, the combination of 3D printing and 3D scanning provides an effective solution through reverse engineering. This approach utilizes 3D scanning to digitally capture a damaged component, in order to reproduce or even enhance the part.

While 3D scanning technology continues to advance, challenges remain in capturing complex geometries and reflective surfaces, as well as seamlessly integrating the scanned data into CAD workflows. This creates a demand for robust hardware and software solutions that deliver precision, meet the stringent requirements of high-performance industries, and ensure exceptional quality outcomes. Creaform, a Canadian company based in Lévis, is embracing these challenges and working to address these issues.

Creaform’s scanning and software solutions guarantee precise results even with complicated surfaces.

Founded in 2002, this leading provider of 3D measurement technology currently offers advanced 3D scanners and software solutions designed to streamline and enhance the user’s workflow. Its efficient solutions for data creation, simulation and quality control significantly contribute to increased productivity and reduced time and costs. Indeed, Creaform’s products are specifically designed to meet these objectives, addressing the needs of a wide range of industries including automotive, aerospace, and manufacturing.

Reverse Engineering for Additive Manufacturing Using High-Performance Scanners

Providing practical reverse engineering solutions for additive manufacturing is central to Creaform’s mission, with innovation serving as the driving force behind these advancements. Creaform’s hardware and software is aimed at industries where precision in design, manufacturing and quality control is key. Creaform’s portable scanning devices (for example the HandySCAN 3D range) are flexible and user-friendly, characterized by their high resolution and detailed scanning results, even when dealing with complex surfaces. The HandySCAN 3D scanners are also equipped with dynamic referencing, which ensures consistent accuracy even in unstable environments.

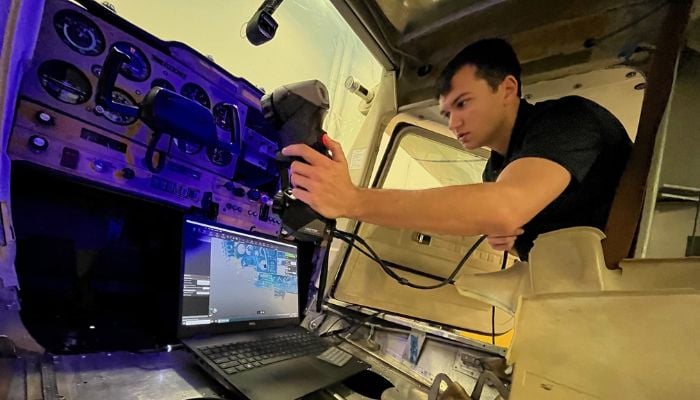

Creaform’s portable HandySCAN series is easy to use and allows great flexibility.

The performance of the portable scanners is demonstrated with numerous use cases from companies who have placed their trust in Creaform’s technology. For example, the POLYAÉRO® Center of Excellence, a competence center for innovative aviation in southern France, used various Creaform scanning solutions to scan the interior and exterior of an aircraft. The data was then analyzed in order to suggest measures for electrifying the aircraft. The scanners from Creaform impressed with their flexibility and accuracy, illustrating the potential for Creaform products in aviation.

Software Streamlines the Scan-to-CAD Process

However, capturing data is only the first half of the job in reverse engineering. The acquired data must then be integrated into the digital workflow so that a CAD model, required for subsequent printing, can be created. The next stumbling block lies at this interface between data capture and transfer. The scan-to-CAD process usually consists of several intermediate steps and is therefore labor-intensive and time-consuming, causing the entire production process to come to a standstill.

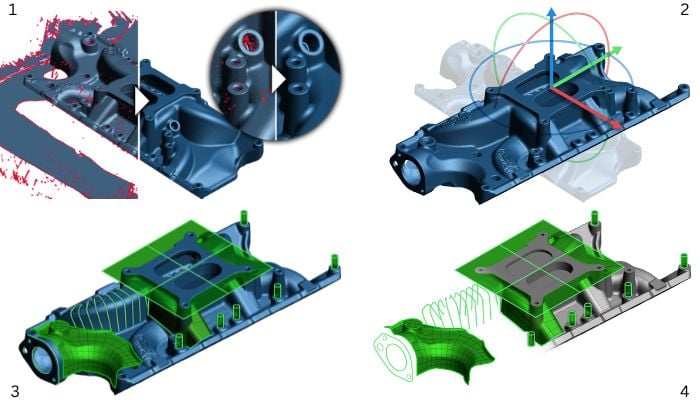

The steps of the scan-to-CAD workflow: mesh editing (1) – alignment (2) – extraction (3) – transfer to CAD (4).

This is another area where Creaform has found a remedy, providing users with ways to simplify these steps. VXmodel post-processing software, part of the VXelement suite, integrates with major CAD platforms, streamlining and accelerating the scan-to-CAD process. It also provides functions such as mesh optimization, surface extraction and precise alignment to CAD models. The faster conversion of data from physical parts into CAD-capable models results in numerous advantages for users. For example, iterations can be completed more quickly, and the optimized process management accelerates time-to-market, ultimately resulting in significant cost savings.

The combination of accurate measurement data for highly complex components and fast conversion to CAD files meets the requirements of a wide range of industries. Sectors such as aerospace, as we have seen, benefit from Creaform’s versatile product portfolio and product flexibility, as do automotive and heavy equipment The seamless ecosystem of 3D scanners and software is also suitable for less experienced operators and simplifies complex work steps for engineers and designers. Manufacturers can quickly reproduce legacy parts or develop new designs based on the captured data. To find out more about Creaform’s solutions, visit the additive manufacturing solutions landing page HERE.

What do you think of Creaform’s scanning solutions? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Creaform