Creaform Makes Scan-to-CAD Seamless For Additive Manufacturing

There are numerous reasons to combine 3D scanning and 3D printing. Reverse engineering and its ability to customize and reconstruct obsolete parts is just one example of the versatility of the duo. While high-quality 3D scanners can capture detailed geometry, transforming that raw scan data into a clean, parametric CAD file suitable for printing is another challenge entirely. Furthermore, converting scan data into a usable CAD file for further processing can be both time-consuming and labor-intensive. In a world where everything seems to work at the touch of a button, this is no longer appropriate. Scan-to-CAD solutions that simplify the transition from scan data to CAD models, thus eliminating efficiencies and enabling companies to overcome various obstacles, are the key.

Let’s first take a look at why the transition from scan-to-CAD can be full of hurdles when using traditional processes. Once the scan has been successfully completed, the data needs to be cleaned up and prepared for further processing. The first step is to align the scan data correctly. Without proper reference points, alignment issues can occur which, in turn, lead to dimensional inaccuracies, causing users to lose time when making adjustments. Secondly, it is important to clean the scan data, as raw data contains noise or gaps that are unnecessary for further processing and could also affect the accuracy of the CAD model. Additionally, converting mesh-based scans into smooth, parametric CAD models is especially challenging for complex or organic shapes, adding further complexity to the process.

Needless to say, quality assurance steps take a significant amount of time, often requiring switching back and forth between different capture tools and CAD software. This time-consuming process is also costly, potentially delaying product launches and requiring trained professionals. So how can a seamless, efficient transition from scan data to CAD model be achieved?

An Efficient Scan-to-CAD Solution for Faster Prototyping and Market Launch

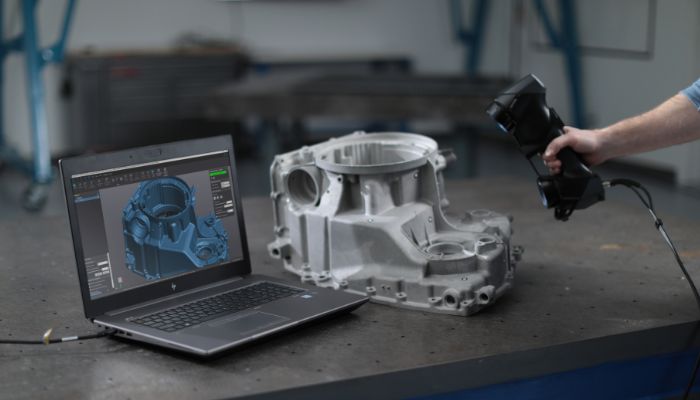

The key to overcoming these obstacles lies in a combination of high-quality data acquisition and intelligent processing. Creaform, a division of AMETEK based in Lévis, Québec, has developed a seamless scan-to-CAD ecosystem by integrating advanced portable 3D scanners with specialized software. The company’s range includes portable and highly accurate 3D scanners for diverse user profiles, as well as innovative software for simple, efficient, and precise data processing. This innovative mix of hardware and software allows users to move quickly from rapid prototyping to market launch, gaining an advantage over competitors.

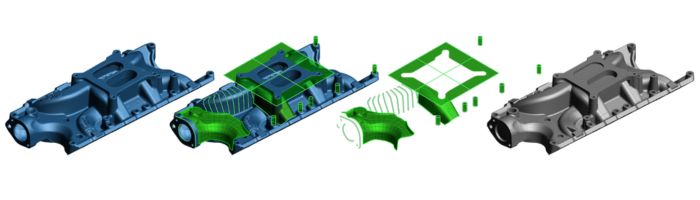

The Creaform Metrology Suite is a robust solution that is able to bridge the gap between 3D scanning and CAD, facilitating high-precision 3D printing. It supports various applications such as product development, reverse engineering, inspection, dynamic tracking, and digital twin creation, optimizing workflow efficiency. Moreover, to enhance reverse engineering and rapid prototyping for additive manufacturing, Creaform includes an advanced Scan-to-CAD module. Available in both standard and Scan-to-CAD Pro versions, it complements the suite’s capabilities with modules for inspection, automation, and dynamic tracking, creating a scalable and adaptable metrology ecosystem.

“Before, users struggled to turn raw scan data to a usable CAD file,” explained David Robichaud, Product Manager at Creaform. “Now, Scan-to-CAD Pro offers the most intuitive reverse engineering toolkit for mechanical engineers and designers. Scan-to-CAD Pro democratizes reverse engineering processes for businesses and users who do not want to invest time and resources in advanced CAD software. It’s truly a market game changer.”

Scan-to-CAD, the evolution of the former VXmodel software package, seamlessly connects 3D scanning to 3D printing by enabling engineers to efficiently align scan data, refine meshes, and generate CAD-ready models. The Pro version adds advanced 2D sketching and 3D modeling tools, accelerating the conversion of scan data into precise parametric CAD models for streamlined design, manufacturing, and additive production.

With Scan-to-CAD, Creaform provides product developers, designers and engineers with a product that guarantees a smooth workflow and ensures precise results while also being user-friendly and easy to operate. It is suitable for a wide range of applications, from heavy industry and aerospace to the automotive sector – sectors in which additive manufacturing is becoming increasingly established and sustainable.

Creaform supports users from these industries and is increasingly focusing its comprehensive product portfolio on compatibility with additive manufacturing. The portable scanning solutions include a variety of models, from versatile all-rounders to high-performance versions, which are continually enhanced with new features and optimized algorithms, according to the company, in order to push the boundaries of precision and efficiency. With the versatile software packages, Creaform builds on its scanning solutions and creates a seamless ecosystem for processing the data, which can then be used directly for 3D printing. Find out more about Creaform’s solutions HERE.

What do you think of Scan-to-CAD from Creaform? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Creaform