The Most Unusual 3D Printing Materials Currently Available

In recent years, the range of 3D printing materials has continued to expand. Nowadays, it is not only plastics and metals that can be processed, but also glass, concrete and ceramics. As part of the circular economy, more and more material manufacturers are also focusing on recycling waste and reprocessing it into 3D printing material. For example, we find recycled ocean waste, industrial waste and wood as filament. In addition, the number of unconventional materials that seem rather surprising in the context of 3D printing is increasing including chocolate, food waste, cigarette butts and even moon dust! Take a closer look at some of the most unusual that we have found in the following list.

Chocolate, the Sweetest 3D Printing Material

This 3D printing material may not be as exceptional as some of the others on the list, but it is certainly among the most used. The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has increased over the years, prompting many companies to develop various projects and even chocolate 3D printers, with the new Cocoa Press notably gathering quite a fanbase among 3D printing enthusiasts. There are a number of different projects centered on chocolate 3D printing including companies like More Than Shape, which seeks to create new taste experiences using this technology, as well as researchers who are using 3D printing to produce an even healthier chocolate. Would you be willing to eat this delicious 3D printing material?

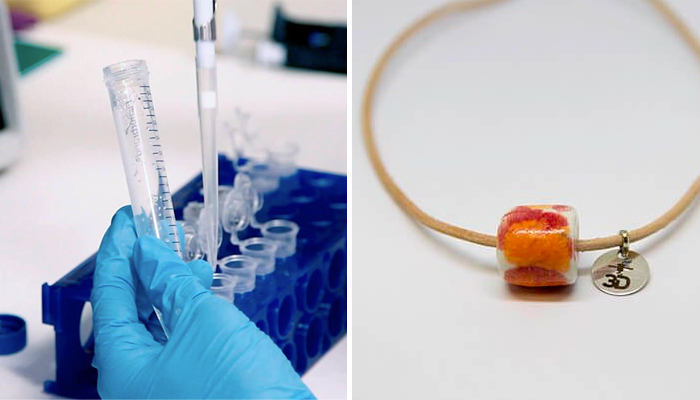

3D Printing Material From Ashes to Remember Your Loved Ones

The Spanish company Narbón is dedicated to introducing new technologies and innovations in the funeral sector. The 3DMemories service uses 3D printing to create original, unique and exclusive ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the pattern must be processed and then combined with porcelain before the jewelry can be 3D printed. Then the enamel is applied and the piece is fixed. The service offers a range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry represents an exceptional way to remember the loved one.

Photo Credits: Narbón

A Different Use for Linen

Another alternative to traditional filaments is a composite material made of PLA and flax from French manufacturer Nanovia. The company says that this composite material is not only a sustainable alternative to traditional filaments, but also offers the possibility of obtaining different shades of brown by applying different printing parameters. This can be achieved by simply changing the printing temperature during the manufacturing process. As far as finishing is concerned, the manufacturer recommends sealing the printed parts with a UV protection treatment so that the printed parts remain intact as long as possible.

Photo Credits: Nanovia.

3D Printing With Sugar

Sugar Lab was acquired by 3D Systems almost ten years ago, but spun out in 2020 and refounded as a direct-to-consumer specialty confections 3D printing company. Using the Brill 3D Culinary Studio, which was originally developed by 3D Systems and called ChefJet Pro, the company creates candy and decorations in complex shapes. The Los Angeles-based company says it is capable of producing candies in all flavors and colors. Whether it’s for birthdays, weddings or Christmas parties, The Sugar Lab offers all kinds of candy from the 3D printer. And as for quantity, the 3D printer seems to be able to produce hundreds of confections per day. While The Sugar Lab is the most well-known company using sugar as a printing material, other companies such as The Modernist Cuisine are also trying their hand at 3D printing with sugar.

A 3D Printing Material Inspired by Ivory

Among the multitude of materials used for 3D printing, there are some that have been developed ad hoc to meet specific requirement and solve old problems in an innovative way. One such material is Digory, which was developed by the University of Vienna in collaboration with Cubicure GmbH to meet the need for restoration of ancient monuments and objects made of ivory. It is a synthetic resin containing calcium phosphate particles and silicon oxide powder. Researchers have developed this new material with ivory-like characteristics and properties to restore objects using SLA 3D printing. The similarity between the two materials is remarkable – there is hardly any difference!

The digory material on the right, is very similar to the real ivory on the left (photo credits: Vienna University of Technology)

Diamond – 3D printing the hardest material on Earth

It may come as a surprise to many that it is in fact possible to 3D print one of the hardest materials on Earth: diamond. Back in 2019, Sandvik Additive Manufacturing announced that it had made the first-ever 3D printed diamond composite. Though it does not sparkle, it would allow manufacturers to 3D print with this super-hard material, helping to revolutionize especially the tooling industry. Diamond has often been used in industries as far-ranged as mining and drilling to machining and medical implants especially because of its wear-resistant properties, but it is hard to machine. With this composite breakthrough, Sandvik claims that it is now possible to 3D print the material in highly complex shapes, and the company has high hopes for its applications in the near future.

3D Printing Materials in Space

Lunar regolith, the gray dust that makes up the surface of the moon, is increasingly being explored for 3D printing. In a study by the University of Central Florida, 3D-printed bricks made of lunar regolith and salt water were developed that could be suitable for the construction of bases in the Artemis base camp. The researchers carried out various tests to determine whether these bricks are suitable for building homes in space. The binder jetting process, which is particularly advantageous for ceramic-like materials, was used in production. The bricks were then printed together with a binder made of salt water and regolith from the UVF Exolith laboratory. Despite the theoretical nature of the project, the results show that the 3D-printed bricks can withstand extreme conditions. Another example is the project by ESA and NASA as part of the Artemis program, which investigated whether space materials such as regolith are suitable for the production of building blocks that can subsequently be used to develop habitats, launch pads or support structures. 15 of these bricks were therefore sold in LEGO stores worldwide. Although 3D printing with moon dust often remains rather hypothetical and is still rarely used, this could change in the near future.

Photo Credits: LEGO

3D Printing With Wool

Wool that cannot be used in the textile industry due to its fineness usually ends up as waste. However, there could be a solution in a new the project from Dutch designer Christien Meindertsma in collaboration with the TFT company. A customized robotic arm called FLOCKS Wobot applies this wool layer by layer, similar to additive manufacturing, and shapes different objects without using additional materials or water. This innovative project is an important contribution to the circular economy and offers enormous potential, as the wool is recyclable, biodegradable and insulating. Future applications could be in the fields of acoustics, insulation, design and furniture construction. D-House, is also researching 3D printing with merino wool. Together with The Woolmark Company and Stratasys, the “Knitting the Future” project was launched, which also involves students from the Royal College of Art in London who want to develop 3D-printed designs from knitted wool. The designers are particularly enthusiastic about the wool, as it enables a wide range of color variations, color gradients and shimmer effects while producing less waste.

Photo Credits: TFT Tools for Technology, Sara Alvarez, Bart Harteloh, Doosan Robotics, Dormac Cobots, Martin Oosthoek, De Wassum, Havivank, Gelderland, Rotterdam Circulair, Lisa Hardon, Creative Industries Fund NL et Stichting DOEN

Food Waste as a 3D Printing Material

There are quite a few 3D printing materials that are made from food scraps or waste from food production. One example is orange peel. The Italian design studio Krill Design, for example, produces 3D-printed lamps based on dried orange peel, which is ground into powder and processed as a biomaterial using 3D printing. A similar project is the “Feel the Peel” machine developed by WASP and architect Carlo Ratti. This is both a juice bar that squeezes orange juice and a 3D printer, as the orange peels are collected, dried, mixed with PLA and form the base material for 3D-printed cups. Citrus fruit waste is not the only raw material that is now being turned into 3D printing materials. In the Cacao Eco Village, for example, cocoa beans and waste were used to produce 3D printed buildings by processing the shells of cocoa fruits into bioplastics. It is also possible to find filaments from some manufacturers that are made from oyster or mussel waste. Smartmaterials offers such a biological printing material and the French filament manufacturer Francofil also sells PLA made from mussel, scallop or oyster waste. In addition to mussel waste, Francofil also sells a filament made from beer waste, in which the brown by-product is turned into a new printing material using PLA. These examples provide an insight into how waste from food production is processed into 3D printing materials. In the context of the circular economy and the trend towards “upcycling”, however, we can find many such innovative approaches.

Can Coffee Be a 3D Printing Material?

Coffee is one of the most widely consumed beverages in the world, with an estimated 2.5 billion cups drunk every day worldwide. So imagine using this consumption to design 3D printing material! A number of initiatives have recently been launched to recycle coffee grounds, i.e. the residue from coffee percolation, by adding a polymer base: the result is a material ready for 3D printing, usually a filament. Among these initiatives is Lowpoly, which has designed 3D-printed furniture for a café, using coffee grounds. Other examples include the University of Colorado and Krill Design.

Organic 3D Printing Materials

When you think of algae or fungi, additive manufacturing probably is not the first thing that comes to mind. However, in recent years, we have seen these organic materials being used for 3D printing in different projects. Fungi, or more specifically mycelium, is being researched for its use as a building material thanks to its eco-friendly nature, as well as in applications such as interior design, consumer goods and even healthcare. Meanwhile, algae have been used for everything from 3D printed organic tiles to more sustainable medicine. Not only that, but algae ink is being developed to help create nutritious food including cultured meat. Both are incredible examples of how additive manufacturing can become an even greener process.

On the left, 3D printed mycelium (photo credits: WASP); on the right, craft tiles made with 3D printed algae (photo credits: bioMATTERS)

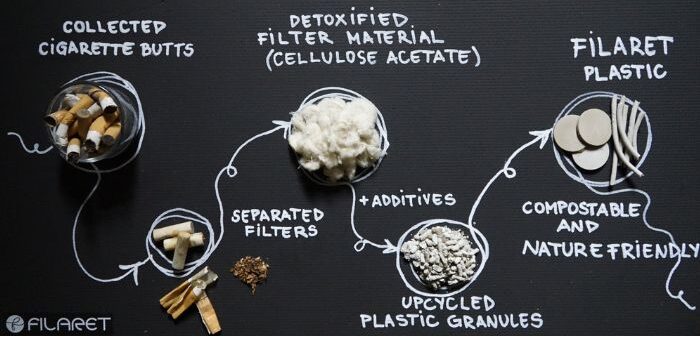

Cigarette Butts

Yes, you read that right: cigarette butts could become the 3D printing material of the future. An initiative that would do our planet a world of good. The aim is to reuse all the cigarette butts that are thrown into nature every day. As you know, they are very harmful to our environment. Just one cigarette butt can pollute up to 500 liters of water or a cubic metre of snow! Imagine that on a global scale. Filaret3D is a company that collects cigarette butts and transforms them into new materials, from paper to 3D printing filament. It takes the filter from the butt, detoxifies and washes it before adding polymers and other additives. All this is transformed into pellets and then into filament.

The process of making filament from cigarette butts (photo credits: Filaret3D)

What do you think of our list of surprising 3D printing materials? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Diamond composite – Diamond ‘powder’ particles and polymer (as a binding agent, a glue). Then post processed in an oven (?) to replicate properties of a diamond (dense super hard composite) by hardening the polymer glue.

But diamonds are not composite. And if the polymer is so strong so as to simulate the C-C bond, why not use powders of other materials like titanium and reduce costs.

Anything is only as strong as its weakest link, and in this case its the polymer.