Could Self-Sensing Materials Be the Future of 3D Printing?

What if 3D printed materials could detect problems before it was too late to solve them? Engineers at the University of Glasgow are working on making that possible by creating a system capable of modeling the physics of self-sensing 3D printed composites. The materials can detect strain, load, and damage using only a measure of electrical current, and this could allow the status of materials to be monitored in real-time, unlocking the potential for safety and quality assurance features for various applications.

How do these self-sensing materials work? According to the press release from the University of Glasgow, “Weaving fine strands of carbon nanotubes throughout materials can allow them to carry an electrical current, imbuing them with the ability to monitor their own structural integrity through a phenomenon called piezoresistivity.” If the electrical current changes, it can mean that the material has been crushed or stretched, permitting the fault to be addressed.

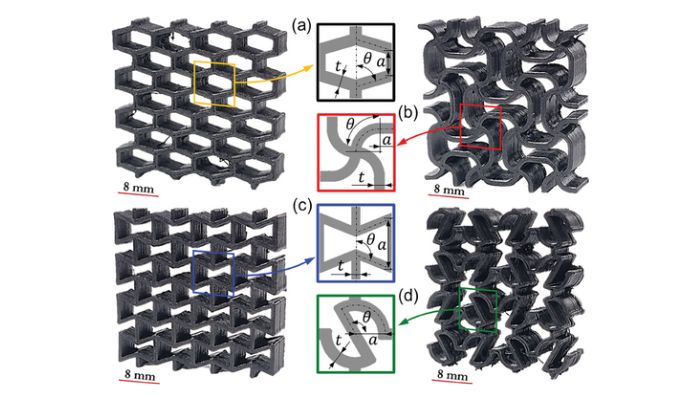

The four different lattices created by the University of Glasgow engineers (Photo credit: University of Glasgow)

Professor Shanmugam Kumar, of the University of Glasgow’s James Watt School of Engineering, led the research. He explained, “Imparting piezoresistive behavior to 3D-printed cellular materials gives them the ability to monitor their own performance without any additional hardware.”

How Were the Self-Sensing Materials Tested?

With their combination of (polyetherimide) PEI and carbon nanotubes, the engineers at the University of Glasgow created four lightweight lattice structure designs with FFF. The lattice designs, which they called autonomous sensing architected materials, were tested for their piezoresistive behavior. Their stiffness, strength, energy absorption and self-sensing capabilities were evaluated, and then, using complex computer models, they created a system to predict how the materials would respond to a varied set of loads.

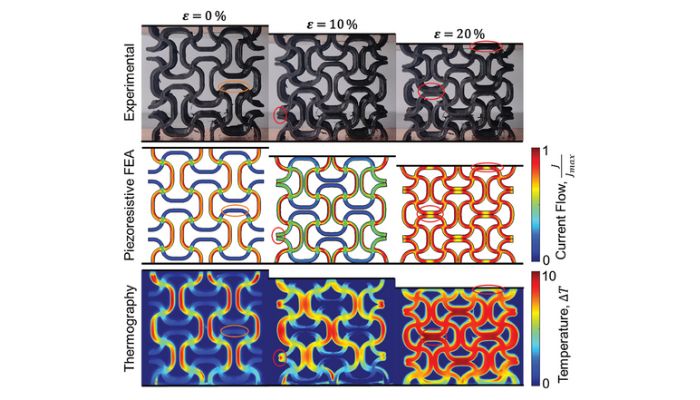

Once the team had their models’ predictions, they validated them by subjecting the materials to intense analysis under real-world conditions. Using infrared thermal imaging, they visualized the electrical current flowing through the materials. With this, they found that their models could accurately predict how the materials would respond to various stress and strain, and how their electrical resistance would be affected.

The lattices and their thermal imaging (Photo credit: University of Glasgow)

Professor Kumar explained how the models they developed will help optimize the development of self-sensing materials.“While researchers have known about these properties for some time now, what we’ve not been able to do is provide a way to know in advance how effective new attempts at creating novel self-sensing materials will be,” Kumar said. “Instead, we have often relied on trial and error to determine the optimal approach for developing these materials, which can be both time-consuming and costly.”

How Could 3D Printed Self-Sensing Materials Be Used?

Self-sensing materials have great potential for diverse applications in additive manufacturing. In the aerospace and automotive industries, the self-sensing materials could enhance safety and maintenance features by enabling real-time structural integrity monitoring in aircraft, spacecraft, and vehicle parts. If self-sensing material is used for structures like bridges and tunnels, it could bring attention to problems before they lead to collapse. The engineers also claim their findings have “profound implications for smart orthopedics, structural health monitoring, sensors, batteries, and other multifunctional applications.”

The engineers expanded on how their research could be continued. “While we focused on PEI materials with embedded carbon nanotubes in this paper, the multiscale finite element modeling our results are based on could be easily applied to other materials which can be created through additive manufacturing too.”

“We hope this approach encourages other researchers to develop new autonomous sensing architected materials, unlocking the full potential of this methodology in material design and development across a wide range of industries.” For more details on the self-sensing material research, read the University of Glasgow’s press release here.

Do you think that self-sensing materials are the additive manufacturing industry’s future? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Polyetherimide (PEI) in pellet form