Could 3D Printing Make Personalized Medications Possible?

It has been clear for a while that 3D printing has a number of benefits for the medical sector. From personalized protheses to bioprinting organs, already AM is being used in medicine in revolutionary ways. However, researchers from the University of East Anglia have found yet another innovative way to use AM. In a recent paper, “Effects of porosity on drug release kinetics of swellable and erodible porous pharmaceutical solid dosage forms fabricated by hot melt droplet deposition 3D printing,” published in the International Journal of Pharmaceutics, the research team outlines how additive manufacturing can be used to 3D print pills which thanks to their highly porous structures could regulate the rate of drug release from the medicine to the body and thus help personalize medications for each patient.

One of the leaders of the research, Dr. Sheng Qi, a Reader in Pharmaceutics at UEA’s School of Pharmacy elaborated on the importance of the project: “Currently our medicines are manufactured in ‘one-size-fits-all’ fashion. Personalised medicine uses new manufacturing technology to produce pills that have the accurate dose and drug combinations tailored to individual patients. This would allow the patients to get maximal drug benefit with minimal side effects. Such treatment approaches can particularly benefit elderly patients who often have to take many different types of medicines per day, and patients with complicated conditions such as cancer, mental illness and inflammatory bowel disease.”

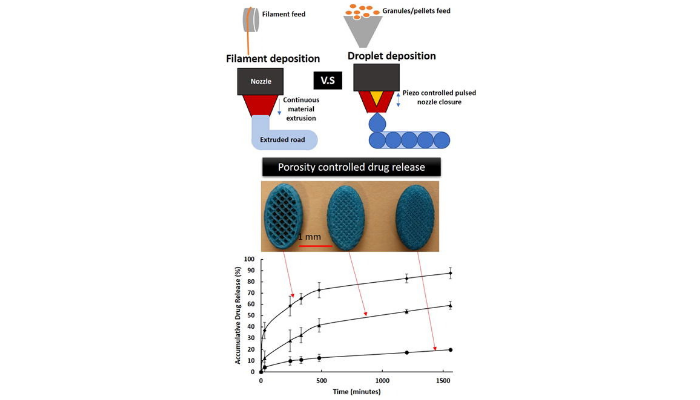

The droplet deposition method as well as results showing how porosity changes drug release time. (Image Credits: Zhang et al.)

According to the study, the team used a newly developed hot melt droplet deposition 3D printing method, most likely similar to or based off of material jetting processes. Unlike with filament disposition, with this droplet deposition granules or pellets will go through an extruder with a piezo controlled pulsed nozzle closure. This will allow researchers to 3D print using drops. If the technology is similar to material jetting, it is likely that there will also be some sort of curing light which will harden the material to form layers. The advantages of techniques such as these are that the surface will be smooth and multiple materials can be printed simultaneously.

3D printing was chosen for the project as it has the unique ability to produce porous pharmaceutical solid dosage forms on demand. As mentioned, the results of the study found that by changing the size of the pores, the speed of the drug leaving the tablet and going into the body could be regulated, allowing doctors to make drugs that will fit each body’s specific metabolic needs.

Along with 3D printing in other medical fields, pharmaceutical 3D printing research has developed rapidly in the past few years. Though often the 3D printing methods require the drug to be processed into filaments before 3D printing unlike in this process which does not require them. The researchers also note that with further research it could also be possible to not only use the porosity to tailor the dose and dosing frequency to each patient’s needs, but could even be used to build multiple medicines into a single daily pill for patients on a complex medicine regiment. You can buy the full study HERE.

What do you think of this research into 3D printing personalized medications? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!