Cornell Researchers Have 3D Printed a Superconductor

Cornell University researchers recently announced that they have created a new way to 3D print superconductors that deliver record-setting performance. Their method was recently published in the ‘Nature Communications’ journal, and specifically uses a one-step printing process that helps simplify fabrication and produces a highly ordered structure. This breakthrough has the potential to advance technologies such as MRI magnets and quantum devices. This shows how additive manufacturing can help streamline the production of materials that once required long and complex processing.

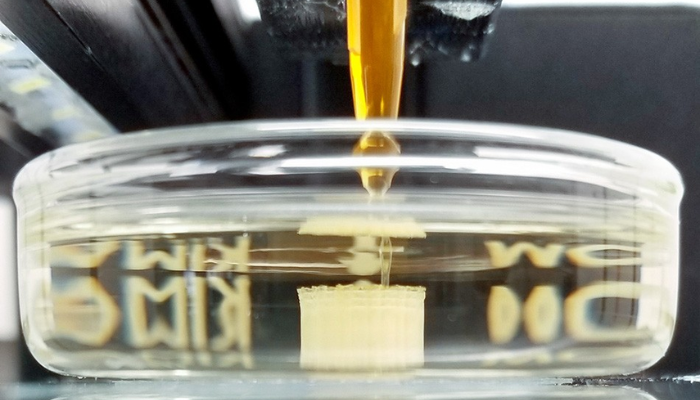

The process used by the researchers relies on a copolymer-nanoparticle ink that organizes itself into nanoscale patterns as it is printed. After receiving a heat treatment, the printed material then becomes a porous crystalline superconductor with properties not achievable through conventional methods. This process helps eliminate multiple preparation steps while allowing for more complex designs. The ability to print directly into functional superconducting forms is what sets this approach apart from previous efforts.

The most striking result came from printing niobium-nitride, a common superconducting material. The 3D-printed version reached an upper critical magnetic field of up to 50 Tesla, which is the highest value ever achieved for this specific compound. Such strength is vital for high-field magnets which are used in the medical and scientific sector. These results confirm that the printed materials are not only faster to produce but also capable of record-breaking performance.

“This has been a long time in the making,” said Professor Ulrich Wiesner, who led the study. “What this paper shows is that not only can we print these complex shapes, but the mesoscale confinement gives the materials properties that were simply not achievable before.” His team also developed a framework linking polymer chemistry to superconductor performance, providing a guide for future designs. According to Wiesner, this type of mapping is a crucial step toward tailoring superconductors for specific technological needs.

Looking ahead, the researchers plan to test other compounds and explore more complex geometries. The porous structures produced by the process also offer large surface areas, which may be valuable in next-generation quantum devices. The method could be extended to transition metal compounds like titanium nitride, further broadening its applications. Together, these results highlight how 3D printing can help shape the future of superconducting technology.

What are your thoughts on these new developments? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Cornell University