CoreTechnologie on the Latest Update of Their 4D_Additive Software

Everyone should be aware that additive manufacturing is not just about 3D printing itself. In addition to post-processing, the use of the right software for creating the 3D-printed model also plays a major role. If you are looking into choosing the right modeling software, then you should be aware of certain essential factors. For example, it is important to know in which industry the additive part will be used, what level of knowledge one has about software, or which features are of particular importance to the user. There is a wide range of different software available, one of which is from the German-French company CoreTechnologie, bearing the name 4D_Additive. In the middle of this year, the software provider presented the update of 4D_Additive, but we wanted to know exactly what new features and improvements the update offers for the user himself. We sat down with Rémi Goupil, product manager for 4D_Additive in Germany, for an interview to learn more about this as well as the company’s future plans.

3DN: Could you briefly introduce yourself and your connection to additive manufacturing?

Rémi Goupil, Product Manager for 4D_Additive in Germany

Hello, my name is Rémi Goupil and I am the product manager for 4D_Additive in Germany. In the 3D CAD interoperability market, CoreTechnologie is well known and the leading global provider for 3D CAD data conversion software. Our mission is to optimize interoperability, helping organizations to efficiently share engineering data and to optimize all processes based on 3D data.

Since its founding in 1998, CoreTechnologie bas consistently presented innovative developments and has more than 560 customers that are leading technology companies developing complex products in the automotive, aerospace, mechanical engineering and consumer goods industry. CoreTechnologie is a Franco-German company with a development center in Lyon, France. The head office is based in Germany, near Frankfurt. As a native Frenchman, it was an optimal solution for me to move to Germany to enable a strong connection between our sales team and our development team in France.

3DN: How did 4D_Additive from CoreTechnologie come about?

Four years ago CoreTechnologie decided to look into the booming additive manufacturing market. We recognized that in our view the few established tools available used outdated data formats and methods based on the triangulated STL Format.

Having 20 years of experience in data conversion and simplification, we noticed a unique opportunity that we can create an innovative 3D-Printing-Software based on our own Kernel handling both exact CAD data of all major formats and triangulated data. So we were able to solve the problem of STL ending up with either large files of sufficient quality or smaller file sizes of poor accuracy. Also the capacity of the printers has evolved considerably to gradually integrate mass production. As a result STL file sizes increased dramatically. So the time was ready to introduce exact and very compact CAD files to support large build spaces and also provide a higher accuracy, especially when it comes to the industrial production of parts. This is the main reason for the birth of 4D_Additive. Furthermore, based on our existing GUI concept, we were able to create an extremely easy-to-use software. The 3D printing market is open to everyone and a solution was needed that was suitable for all types of users, while offering high quality parts and more processing power for a serious Additive Manufacturing Process.

3DN: CoreTechnologie released a new version of the software in the middle of this year. What can you tell us about the new features in the 1.4. Update?

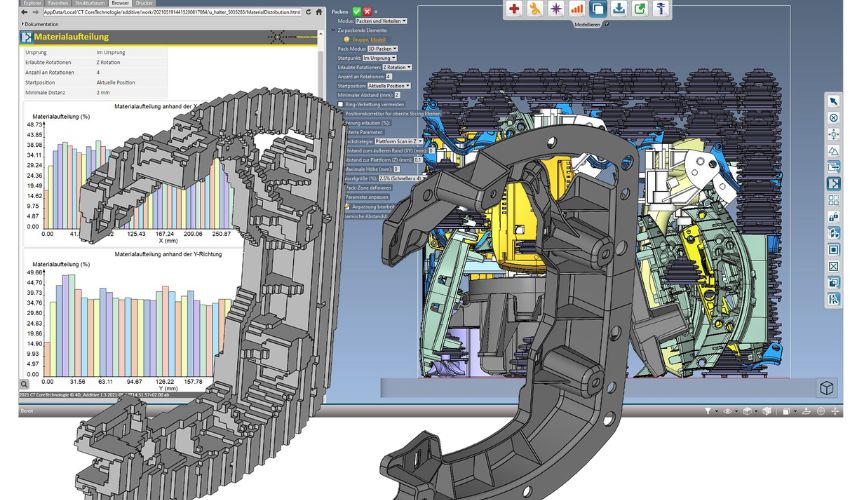

The highlight of the new software version is surely the improved nesting functions. Compared to our previous version, the software now offers higher speed, accuracy and packing density as well as further optimized packing distribution. In addition, the software has a new nesting strategy. The new Powercopy nesting function allows for an extremely fast packing of identical parts with a maximum packing density. In addition we integrated the Eosprint 2.0 interface. So now print data can be sent from 4D_Additive directly to EOS machines without detours via other software tools or formats. This makes it possible to read native CAD or STL data, prepare it for the 3D printing process and send the data now also to EOS systems with a single software tool.

3DN: What is the primary target audience for 4D_Additive?

Our customer base are 3D printing service companies and the prototyping industry but we also increasingly see that mechanical engineering companies are buying our software. Today, more and more parts are being designed as 3D printing parts and need to be manufactured on a regular basis. Therefore, we are concentrating on the automation potential for powder bed technologies such as SLS and MJF and 3D nesting, which is a crucial technology to improve productivity. In our latest version, we also spend a lot of development time in FDM and DLP support structures and to write the G-Code for major printers. Our goal is to provide one solution that can be used for all printing methods and machines without the need for users to switch between many different software.

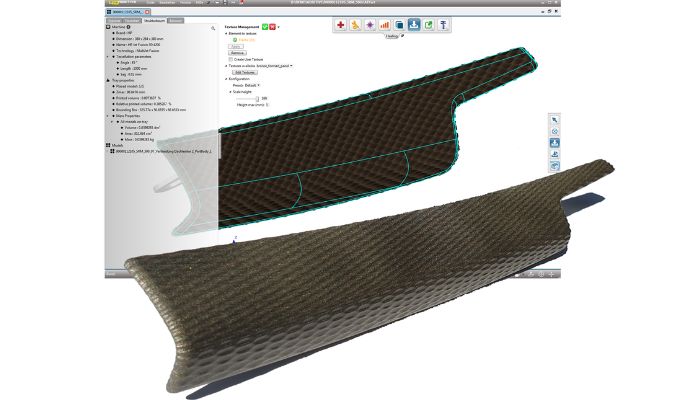

The texture can be chosen using 4D_Additive.

3DN: What projects can we look forward to in the future from CoreTechnologie?

For the upcoming version in November we are concentrating on support structures for metal printing and on some new AI based algorithms to automatically optimize supports as well as the part orientation. This month we will present a first version of our automatic batch nesting tool that can be easily integrated in all web server systems by means of a so-called Rest API.

Last but not least we just finalized our SLS build manager and are now working on the 4D_Additive API that will provide advanced functions like 3D nesting, slicing, hatching and support generation in an easy to use Software Developer Kit.

3DN: Do you have any final words for our readers?

We see a great potential in 3D printing especially when it comes to achieve more independence from the vulnerable supply chains. Talking to our customers we can also see a serious and consistent change from classical production methods like injection molding towards Additive Manufacturing, especially when it comes to smaller and complex parts as well as small batches. You can find out more on our website HERE.

Have you already had experience with 4D_Additive? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: CoreTechnologie