CONCR3DE: Rebuilding Palmyra Arch with 3D Printing

CONCR3DE is a Dutch company focused on using 3D printing to create environmentally friendly structures using their innovative technology and new materials. Some of their recent projects include recreating Palmyra Arch after it was destroyed by ISIS using their stone material. Therefore, we had to sit down with the team and find out more about this innovative new company.

3DN: Introduce yourselves, and what CONCR3DE focuses on in the 3D printing industry?

My cofounder Matteo and I both have a background in architecture and design and we got a bit frustrated with how difficult it was to make unique, beautiful objects. Manufacturing right now can be very wasteful through for example using molds that need to be discarded, and a whole range of subtractive processes. We were looking for a way to make production cheap, clean, high-end and local. This is why we started CONCR3DE, a company that focuses on large scale inkjet 3D printing. We developed a new material for this process, a kind of stone. This allows us to print a strong, heavy material in a very sustainable way, as there is no polluting cement involved.

Through this, we can print very precise objects, with large geometric freedom, in a clean way.

CONCR3DE have developed a new 3D printing stone material along with their inkjet 3D printing technology.

3DN: How did you get involved in the 3D printing industry?

Through our architecture/design background really, it’s an essential tool in prototyping. We’ve used it at university and professionally and felt the current technologies for large scale 3D printing are severely lacking because they’re either imprecise, lack strength, use unsustainable materials, or are extremely expensive. This company wasn’t necessarily born from a general interest in 3D printing – it was that we didn’t get what we wanted out of current 3D printing so we thought we’d change that.

3DN: What are some recent projects CONCR3DE have worked on?

We’re mostly doing R&D right now, developing our large 3D printer that we’ve funded with a recent investment round. We’re not really in full on production mode.

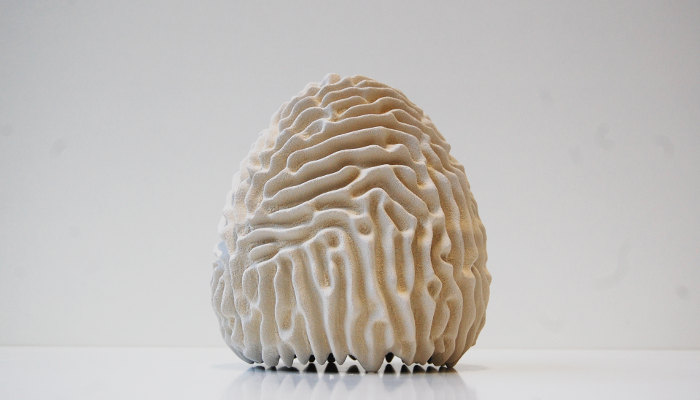

A small project that we’ve been doing is the Coral Lamp, a unique 3D printed stone lamp that is modeled around structures found in brain coral. We’re working with Transnatural, a cool label in Amsterdam, to bring it to the market.

Another project we’re involved with is #NEWPALMYRA, an initiative to remodel and preserve the ancient Roman city of Palmyra in Syria. It was unfortunately destroyed by ISIS in 2013 in the Syrian Civil War. The #NEWPALMYRA group created a platform where people can remodel the ancient city based on old photos and drawings in 3D. Our technology is the only technology that allows you to print the objects in a real stone material with the precision and geometric freedom that is required.

Lamp design based on brain coral.

3DN: What about 3D printing are you most excited about for the future?

I really enjoy that we’re seeing a move away from the hype that it was a few years ago to real use cases in manufacturing, architecture, restoration, etc. Slowly I think it this technology will inevitably become just another way of production, similar to other production technologies and it’s important that people are aware of the advantages and disadvantages of it. From our side we’re definitely trying to move from 3D printing purely for prototypes to 3D printing finished objects with a long life cycle and real world applications.

3DN: What are CONCR3DE’s plans for the future?

We’re developing our ‘Rhino’ 3D printer right now. It’s a very large inkjet 3D printer that can print objects larger than 3.5m³, with direct applications in construction and design as well as manufacturing molds. We’ll open our factory, the PROTOTYPE FACTORY in 2019, which will become a facility where we will 3D print all kinds of unique, highly sustainable and beautiful projects.

We’re also looking to hire engineers to work with us on this machine, so if any readers have a profile in mechanical engineering/mechatronics they’re welcome to reach out to er**@******de.com.

Check out CONCR3DE’s website here.

What do you think of CONCR3DE’s plans for 3D printing? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!