From Trails to Tackle Boxes: How 3D Printing Is Reshaping Outdoor Gear

When it comes to spending time outdoors, preparation matters. Whether hiking, camping, fishing, or hunting, having the right equipment on hand can make a real difference. Because this gear must be carried (and often, over long distances), it needs to be lightweight, functional, and well-designed. As a result, many companies are turning to 3D printing to develop and refine outdoor accessories. Additive manufacturing allows for greater design freedom, opening the doors for customized, lightweight, and high-performance components. Backpacks, protective cases, hiking pole add-ons, and tent stakes are just a few examples of how the technology is being applied in outdoor contexts. Sustainability also plays a role, with manufacturers exploring new materials and production approaches to limit waste and environmental impact. Check out how companies are using AM to level up their outdoor game below!

Teragon Gear: Offering Better Tent Stakes

The Norwegian company Teragon Gear has a mission to recreate tent stakes. The company’s Pioneer series tent stakes promise an unmatched strength-to-weight ratio, with a minimum 40% weight savings compared to an average Y-beam tent stake. The secret is that the stakes are 3D printed out of titanium, offering improved durability compared to aluminum stakes. There are three models in the Pioneer series: the Pioneer 1, Pioneer 2, and Pioneer Torque. Teragon Gear claims that the shortest of their stakes, the Pioneer 1, is the lightest metal y-beam stake on the market, weighing in at 5.3 grams (0.18 oz).

From left to right, the Pioneer 1, Pioneer 2, and Pioneer Torque stakes. (Photo Credit: Teragon Gear)

CleanTrek: Cleaning Up on Your Hikes

What if you could easily pick up the trash you come across on your hike? Unfortunately, it’s a reality that more and more trash is being left on our trails, polluting our environment every day. The CleanTrek project offers a solution to this problem: it has created the first hiking poles equipped with a waste collection system. There are three key elements to this: the “Trigger” located near the handle of the pole. Simply push it to activate the “Grabber” at the bottom, which allows you to pick up waste without bending down. Then there is the “Collector,” which is a kind of trash can in which you place the collected waste. And what interests us, as you might expect, is how these key components are manufactured. They were produced on an HP machine using Multi Jet Fusion technology. The project’s backers, currently on Kickstarter, seem to indicate that additive manufacturing will not be favored for mass production. Injection molding is more attractive in terms of cost and lead times for the desired quantity.

Sierra Seasonal: Custom 3D Printed Cases for Outdoor Gear

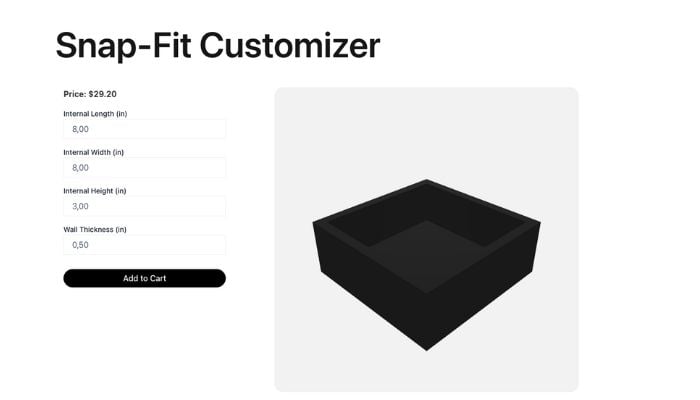

One-size-fits-all solutions rarely make sense for outdoor equipment. Sierra Seasonal builds 3D-printed outdoor cases designed to fit gear as it is actually used, with durability, organization, and portability in mind. Through its online Case Builder configurator, users input precise measurements and customize wall thickness and layouts, resulting in lightweight, snap-fit cases printed to match real gear dimensions rather than generic sizing. This print-to-fit approach maximizes available storage space, keeps equipment secure and organized, and supports efficient, grab-and-go packing without unnecessary bulk. By relying on additive manufacturing for on-demand, small-batch production, Sierra Seasonal demonstrates how 3D printing enables practical mass customization that would be difficult to achieve with traditional manufacturing methods.

Online Snap-Fit Customizer (Photo Credit: Sierra Seasonal)

Jack Wolfskin: Aerorise Backpacks for Extreme Ventilation

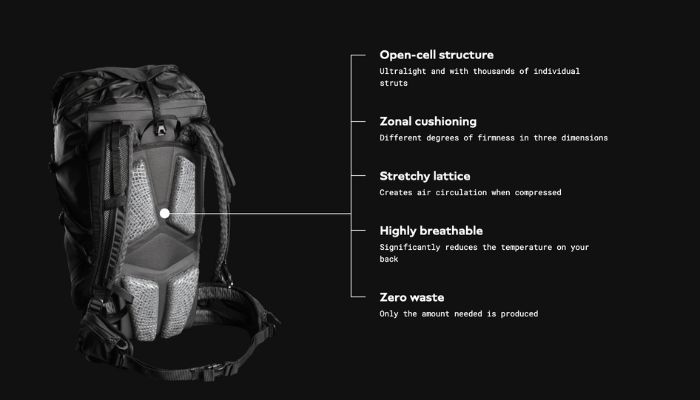

German company Jack Wolfskin has introduced the 3D Aerorise backpack series to innovate the weight distribution system on the back. The technology, developed in collaboration with Carbon, replaces traditional foam padding with four panels printed in 3D using Digital Light Synthesis (DLS). The lattice structure of these panels allows the degree of rigidity to be varied at specific points, optimizing load stability and dramatically improving ventilation compared to conventional systems. In addition to technical performance, the use of additive manufacturing reduces production waste and eliminates the use of synthetic adhesives in the assembly of the backrest.

The Aerorise backpack (Photo Credit: Jack Wolfskin)

A3D Outdoors: Integrated Electronics for Ice Fishing

The American company A3D Outdoors uses additive manufacturing to simplify the integration of electronics into sport fishing. Its flagship product, the Ice Power Shuttle, is an all-in-one frame designed to house fish finders and batteries in a single lightweight structure. Thanks to 3D printing, the system natively integrates components such as USB-C voltmeters, transducer arms, and rod holders, offering a compact and durable solution that reduces bulk and weight when transporting on ice. The flexibility of the design also allows compatibility with leading Garmin, Lowrance, and Humminbird devices, adapting to different battery sizes.

(Photo Credit: A3D Outdoors)

Jereko Gear: Trail-Ready Outdoor Accessories

Designed by an engineer with a deep connection to the outdoors, Jereko Gear blends mechanical engineering with hands-on trail experience to develop practical, 3D-printed outdoor accessories. Drawing on more than 16 years in outdoor education and the outdoor industry, the brand creates lightweight, functional components such as bike mounts, cargo cages, hydration system hangers, and replacement parts that address everyday gear issues encountered in the field. Additive manufacturing allows Jereko Gear to iterate quickly, produce small batches, and keep products affordable using plant-based plastics, while also supporting repair, upcycling, and consignment programs that extend the life of existing equipment. Together, these elements reflect an approach to outdoor gear design that prioritizes function, durability, and environmental responsibility.

3D Printed Light Lug and Carabiner (Photo Credit: Jereko Gear)

Osprey: The FitscapeLumbar for More Comfortable Backpacking

The American brand Osprey has been making quality backpacks for outdoor adventures for more than 50 years. But in 2022, the company came out with the UNLTD line, a series of backpacks especially designed to incorporate cutting-edge technologies. The series features the 3D printed “FitscapeLumbar,” made with Carbon’s DLS TechnologyTM. This lattice structure panel comes into direct contact with the wearer’s back, offering supreme ventilation, fine-tuned support, and anti-slip grip. Thanks to the capabilities of 3D printing, the panel also has three layers and zones of resistance, offering unique support and comfort.

The Osprey Airscape 68 (Photo Credit: Osprey)

Genesis 3D Printing: Modular and Silent Accessories for Hunting

The US company Genesis 3D Printing specializes in developing modular solutions for mobile hunting and technical camping. The company uses additive manufacturing to transform complex concepts into functional accessories, such as the G3D Gear Hanger System and the SSS (Stick-Stack-Stow) system. These components are designed to organize equipment in elevated locations, offering an ultra-lightweight and silent alternative to traditional metal hooks. Taking advantage of the design freedom of 3D printing, Genesis creates compact hook systems that improve hunters’ logistical efficiency, eliminating unwanted noise and drastically reducing the overall weight of the load.

Example of their products: G3D Gear Hanger System (left) and Universal SSS System (right). (Photo Credit: Genesis 3D Printing)

Tackle3D: Affordable Fishing Gear

Established in 2024 and located in the North West of England, Tackle3D began as a personal hobby that merged 3D printing technology with a passion for angling. The operation identified a gap in the market for affordable, high-quality gear, and now offers a catalog “designed by an angler, for the anglers.” This includes everything from fishing pole accessories, pellet cutters, and more. The company ensures compatibility with top brands; for example, they produce specific pole nose cones for major manufacturers like Daiwa, Preston, and Matrix, alongside organizational tools like winder insert trays and rig station accessories. The team’s AM approach allows them to refine products based on direct customer feedback to make sure their designs are constantly evolving to improve performance.

(Photo Credits: Tackle3D)

Lemki Robotix: A Camper Van for Getting Away from it All

Lemki Robotix is a German-Ukrainian startup that has created a 3D-printed camper van. Called DISCOVER 3D, it was made using a large-format 3D printer and plastic granules. More specifically, the bodywork was printed using recycled polypropylene from 7,400 plastic bottles, to which glass fibers were added. The startup favored composite materials and drew heavily on the shapes found in nature to design its camper van. In any case, it is fully equipped and will allow you to enjoy a relaxing vacation in the great outdoors! It is also 20 to 40% cheaper than traditional solutions on the market.

(Photo Credits: Lemki Robotix)

What do you think of using 3D printing to create outdoor gear? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.