Researchers mimic nature for colorful 3D printing

Researchers from the University of Illinois are demonstrating how additive manufacturing technologies can be used to produce multiple colors from a single ink. More specifically, the research paper entitled “Tunable structural color of bottlebrush block copolymers through direct-write 3D printing from solution”, was published in the journal Science Advances, and explores how 3D printing materials can reflect color by using nanoscale structures, called photonic crystals. This latest research is interesting as it showcases how new applications can be unlocked by studying AM materials rather than the printing process. As 3D printing technologies have matured, the next revolution seems to lie in material development.

In fact, Physical Sciences Editor at the University of Illinois News Bureau, Lois Yoksoulian explains that some of the most vibrant colors are found in nature. Therefore, looking at the phenomenon behind these vibrant colors can give scientists clues as how to achieve this using technology. He goes on to explain that the phenomenon is known as structural coloration (occuring at the nanoscale level). “When light rays reflect off these periodically placed structures located in the wings and skins of some animals and within some minerals, they constructively interfere with each other to amplify certain wavelengths and suppress others. When the structures are well ordered and small enough – about a thousand times smaller than a human hair, the rays produce a vivid burst of color.”

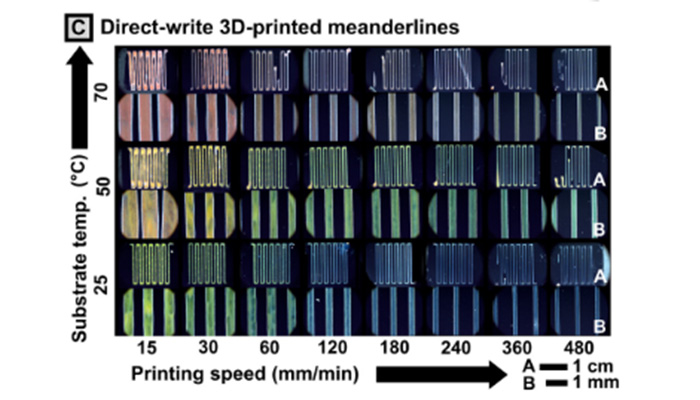

The speed and temperature of printing dictate the colors that we see

Therefore, in the polymer world, achieving nanoscale precision is key to obtain these colors. Ying Diao, a chemical and biomolecular engineering professor at the University of Illinois at Urbana-Champaign commented: “Precise control of polymer synthesis and processing is needed to form the incredibly thin, ordered layers that produce the structural color as we see in nature.” By carefully tuning the assembly process of uniquely structured bottlebrush-shaped polymers during 3D printing, researchers were able to print photonic crystals with tunable layer thicknesses that reflect the visible light spectrum from a single ink, according to the research paper. With work at the nanoscale level, one limitation is often scaling up because the level of precision that is required does not allow to 3D print quickly.

As a result, the team of researchers used a modified consumer 3D printer to fine-tune how fast a printing nozzle moves across a temperature-controlled surface. “Having control over the speed and temperature of ink deposition allows us to control the speed of assembly and the internal layer thickness at the nanoscale, which a normal 3D printer cannot do,” said Bijal Patel, a graduate student and lead author of the study. “That dictates how light will reflect off of them and, therefore, the color we see.”

Additionally, the team is working on expanding the industrial relevance of the process, as the current method is not well suited for large-volume printing. It’s true that the next revolution in additive manufacturing seems to be related to materials. Today, manufacturers and researchers are often limited by the availability of different materials rather than the 3D printing process itself. Bijal Patel concluded: “This work highlights what is achievable as researchers begin to move past focusing on 3D printing as just a way to put down a bulk material in interesting shapes. Here, we are directly changing the physical properties of the material at the point of printing and unlocking new behavior.”

You can find more information HERE. What do you think of creating many colors from a single ink using additive manufacturing technologies? Could this process be scaled up? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!