CMT Additive Pro: Fronius Impresses With 3D-Optimized Welding Process

The flexibility in design and customization, the elimination of casting molds and the low material consumption paved the way for metal 3D printing and ultimately ensured its successful entry into various industrial applications. Nevertheless, metal additive manufacturing is not immune to challenges. Technologies and systems need to be developed that allow material- and cost-efficient processing and deliver stable, reproducible results. This is the aim of Fronius CMT Additive Pro. This characteristic line designed for additive manufacturing combines Fronius expertise in welding with innovative 3D printing to enable new applications.

In 2005, the Wels, Austria-based company Fronius developed its Cold Metal Transfer (CMT) technology, a stable, controllable welding process that is comparatively “cool” due to its reversing wire movement. This is perfect for additive manufacturing due to its low spatter and high process stability.CMT Additive Pro is a new 3D-optimized welding characteristic for the Fronius iWave Multiprocess PRO and enables the cost-effective and precise production of components using the WAAM process.

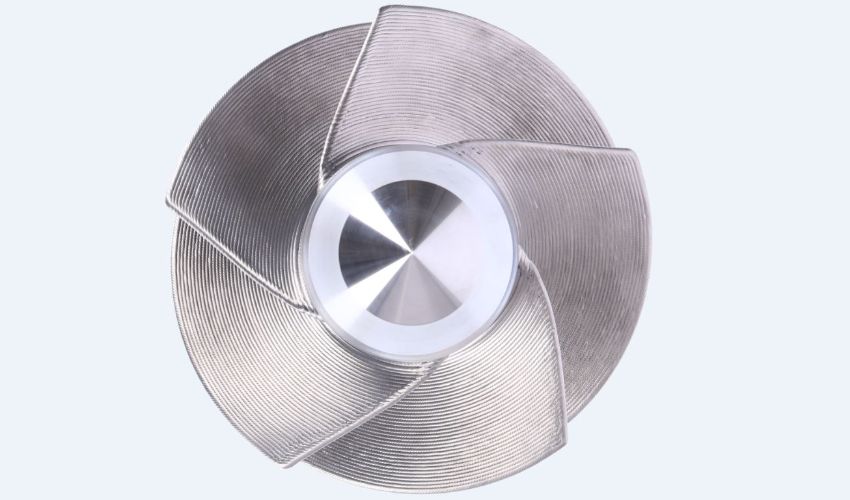

A sample qualification is being carried out in this image

In addition to a stable arc, heat management is also crucial for high-quality additively manufactured parts. Thanks to innovations such as the deposition rate stabilizer or power correction, CMT Additive Pro makes it possible to achieve a uniform layer build-up and ensure a high level of reproducibility. Other features include Pulsed HotStart, which enables a simple welding start in the pulsed arc and achieves sufficient penetration and a constant layer height without changing the operating point, as well as CTWD value measurement, which measures in real time and was specially developed for materials with low electrical conductivity such as steel.

With this optimized WAAM process, Fronius is responding to existing challenges in metal 3D printing and, with the CMT Additive Pro characteristic line, offers a solution for processing complex geometries with a consistently high deposition rate. The stable process, the variety of materials and printing on demand offer advantages for numerous applications, whether for prototypes, spare parts or small series. The cost and material efficiency also speak for themselves and round off the package.

CMT Additive Pro is also compatible with a robotic system

Together with the new iWave Multiprocess PRO, the Fronius CMT Additive Pro characteristic line, which is designed for efficient 3D metal printing, offers a complete solution for additive manufacturing and the repair of metal parts. The complete package is also compatible with common robot systems, thus expanding the range of applications and possibilities in additive manufacturing. You can find out more about Fronius and its innovative CMT Additive Pro characteristic curve HERE.

What do you think of the CMT Additive Pro? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Fronius