New clay 3D printer from 3D Potter extends current capabilities

The 3D printer manufacturer and ceramic studio based in Florida 3D Potter, has just unveiled their newest compact size clay 3D printer – the Scara Mini V1. The company already supplies its real clay 3D printers to over 200 universities, art galleries and it is the preferred printer at a large US-based chocolatier. The Scara Mini V1 is a lightweight, high-powered, low-pressure machine that should extend beyond the current capabilities of 3D ceramic printing. How so? It uses a cardinal axis system rather than a delta printer configuration, allowing precise control with minimal effort. Additionally, many clay 3D printers use a pressurized system with compressed air, however, theirs use no high-pressure systems, just an overgrown syringe.

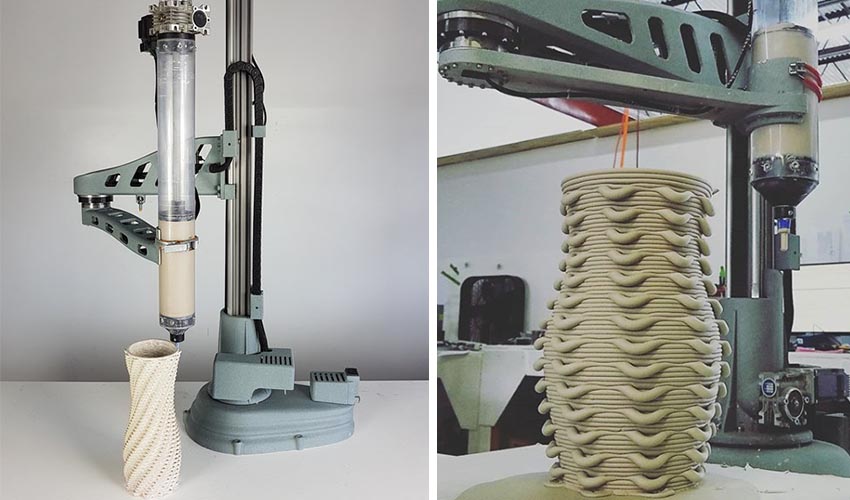

The Scara Mini V1 clay 3D printer from 3D Potter is compact and capable of printing multiple objects non-stop | Credits: 3D Potter

The Scara Mini V1 is the compact version of their largest Scara V3 – the company counts multiple clay 3D printers. This latest model counts both 1-joint robotic arms and rotational x and y-axis features which are beneficial for printing height, accuracy, and quality of print. Indeed, the manufacturer explains that there is no weight limit to the printed object and the final result should have an even consistency with virtually no air bubbles. The 2000mL extruder is easy-to-clean and since it is not a high-pressure system, real clay can be used from any source, food or cementitious materials.

We recently told you about ceramic 3D printing reports that predicted this segment of additive manufacturing to generate up to $3.6 billion worldwide by 2028. Although not as well established as plastic technologies or even metal 3D printing, ceramic 3D printing should spread and reach maturity as a manufacturing technique for different industries by 2025. Clay has always been the most commonly used material when manufacturing ceramic materials, largely due to the fact that it is a natural ingredient, easy to find in almost any environment.

Moreover, this clay 3D printer is capable of providing extraordinary benefit to institutions of higher education and to architects. Danny Defelici, Thought Leader at 3D Potter explains, “The other advantage for universities and architectural departments is that it can do architectural objects. It can actually print inside the object.” The machine is easy to set up – apparently it is a one-person installation process and can be used on the floor or on a table.

*Cover photo credits: 3D Potter

What do you think of this clay 3D printer? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Hi can I please get more information on these ceramic 3d printers and price.

thanks

Dewald

Ik vind dit een fantastische verbetering ,en ben benieuwd naar de prijs, wij zijn bezig met de ontwikkeling van een totaal nieuw concept

Fijne Groeten Jozef Jansen