Choosing the Right Lattice Structure in 3D Printing

When you ask those in the know what the benefits of additive manufacturing are, there is one thing that comes up time and again: design freedom. With the right design software, users can create incredible parts that are lightweight and more optimized than what can be achieved with traditional manufacturing. This is especially important when it comes to lattices, which are unique to 3D printing and widely appreciated for their characteristics. This is why many different software have enabled the creation of lattices, including Altair Inspire, which includes complex lattice structures.

You may already know Altair Inspire. Coming from Altair Engineering, a global leader in computational science and artificial intelligence headquartered in the USA, Altair Inspire is one of the company’s software solutions that is uniquely suited to additive manufacturing. This concept design tool has a number of interesting features that are well optimized for additive manufacturing. The ability to use the tool with different lattices is a particularly favored characteristic according to TrueInsight, the premium channel partner for Altair Engineering.

These repeated patterns, inspired by biomimicry, can fill a volume or conform to a surface and for the most part can only be made with additive manufacturing. This is one of the reasons that they can be confused with infill as they can be used for that purpose. Their unique benefit is that they enable a superior strength-to-weight ratio due to minimizing material while still ensuring part performance.

But lattices are not one size fits all. To better understand the different lattices and their use in 3D printing, we have outlined them in the following guide. Here, we will discuss the characteristics of each lattice type, how they differ, how they are used and more.

Which Lattices Can You Use in 3D Printing?

Lattices are prized for their ability to make part lighter and stronger, reduce part volume (leading to fewer surface defects and preventing excessive stress build up), reduce material use, superior energy absorption (which is why they are often used in sports) and increase surface area. But these advantages differ depending on the type of lattice used. That is why it is important to look at each different guide to better understand when they should be utilized.

The four different lattice types

Surface Lattice

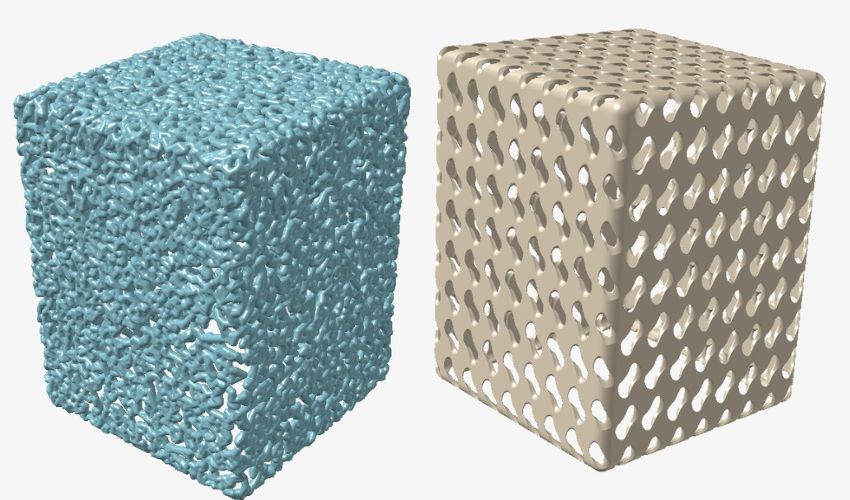

First up are surface lattices, which you have almost definitely seen being used for applications like heat exchangers. This cellular structure is made from one or sometimes two surfaces. Here, the natural repetition of surfaces is what creates the lattice structure, as opposed to tiling or patterning a base unit cell. Generally, these types of lattices have all-around good mechanical properties.

Common examples of this are Triply Periodic Minimal Surfaces (TPMS) and gyroid lattices. Gyroids in particular are very effective in heat exchangers when compared to the traditional shell and tube versions. This is because heat transfer rate is proportional to the available heat transfer area and these types of lattices have a large surface area due to their nature. This makes them useful for thermal management. However, one challenge is that they do not always have a uniform conclusion, in contrast to a strut lattice. This can lead to small overhangs.

Planar Lattice

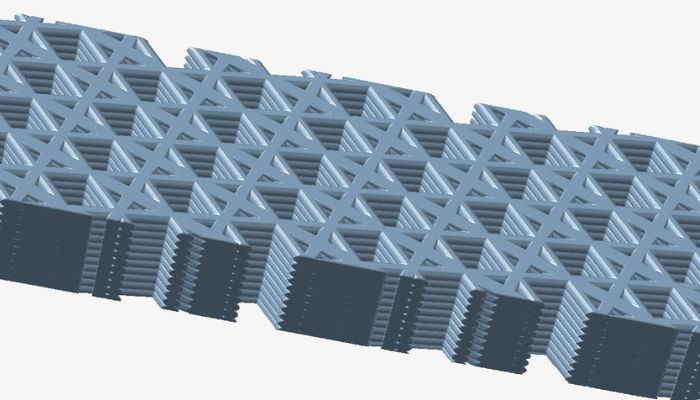

Meanwhile, planar lattices are often used in consumer goods as generally it is an extruded cross section shape. Think of honeycomb, or many surfboards, that also use planar lattices in their design. To separate it from surface lattices, here Altair defines a planar lattice as “a 2.5D cellular structure with a clearly defined 2D cross-section that is drawn or extruded along the third dimension.” These types of lattices offer high stiffness in a specific direction. This is also the only lattice that can be made using other techniques, namely extrusion due to the fact that it is a 2D cross section rather than 3D.

Strut Lattice

Strut lattices are constructed from nodes that are connected by beams. How you can think of it is that there is a base cell that is tiled and then patterned in one, two or three dimensions to form the lattice structure. Generally, this lattice structure is more uniform than a planar lattice but also complex. Due to their nature, these lattices can take many different forms depending on the cell type. For example, a body-centered cubic will be made starting from the center of the body while a face-centered primitive could be thought of as the outside of a box. There is also cubic primitive, isotruss, octagon, hex truss, kelvin cell, fluorite, diamond, truncated cube and octet.

A close up on strut lattice

Where these lattices are often seen is in structural or architectural applications. For example, they can be used for aerospace applications because the pattern is very repeatable in contrast to some of the more chaotic patterns that can occur with other lattice types. They are well known for being able to create a lightweight but strong framework and are valued for a high strength-to-weight ratio.

Stochastic Lattice

Last but certainly not least, stochastic lattices were one of the most anticipated lattices in Altair Inspire’s latest update. For those who may not know, stochastic means “having a random probability distribution or pattern that may be analyzed statistically but cannot be predicted precisely.” It should come as no surprise therefore that stochastic lattices are essentially randomized strut lattices where a user has just “defined the points, edges between points, filters to remove certain points and/or edges, a method to thicken edges into struts, and outer body treatments such as combining the lattice with an outer body or shell.”

In many ways, this lattice is the one that most closely resembles nature, more specifically bone. Indeed, stochastic lattices are often used for biomedical applications. Take once again the example of a bone. These have two parts, the cortical, which is the hard outer surface, and trabecular, or the spongy interior. Cortical are pretty easy to characterize and replicate, but trabecular has posed a real challenge due to its randomized nature. This is where stochastic lattice comes in.

Stochastic lattice can characterize randomness more easily. Essentially, if you are looking for osseointegration, or bone ingrowth into an implant, stochastic lattice is the way to go. For example, they are popular when making implants.

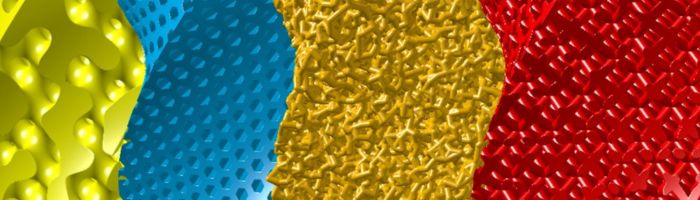

Lattices can be made of different patterns, depending on the type used and the needs of the part

How Altair Inspire Sets Itself Apart

So, there you have it. It’s not really possible to say which would be the best lattice for 3D printing, rather it is necessary to look at the different ones and see which best suits the part. What certainly helps however is software where lattice structures can be automatically added.

Altair Inspire is a good example of this. Surface, strut, planar and stochastic lattices can all be made quickly by going to the Implicit Modeling ribbon and selecting the desired lattice tool. After that, it is possible to select visualization quality as well as the bodies that will be filled with the lattice among other options, as can be seen in the video below.

Indeed, the use of implicit modeling rather than BREP (boundary representation) CAD creation like most traditional CAD software, is one of the major points setting Altair Inspire apart. What exactly does this mean? Well, with most traditional CAD, to create lattice it would be necessary to construct a series of NURBS surface patches before assembling these into a lattice unit cell. Then that unit cell will be patterned in 1-, 2-, or 3-dimesnsions to form a lattice. This is BREP CAD creation.

According to Altair, this method gives tight control over lattice geometry, however it does not scale well. This is due to the fact that as the number of unit cells increases, the CAD package will slow down to the point of being unusable.

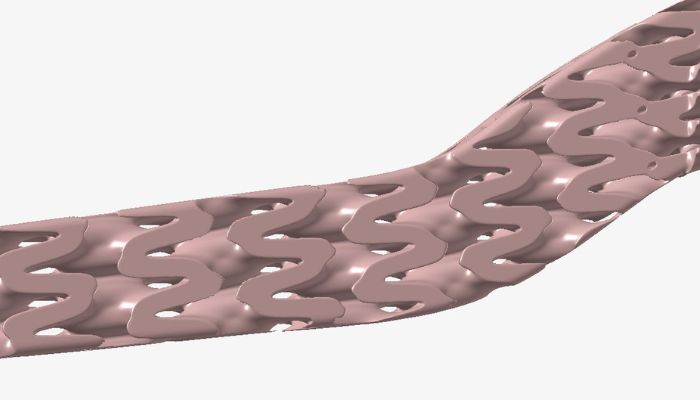

Implicit modeling is particularly suited to the creation of surface lattices, such as this example

In contrast, implicit modeling makes use of implicit surfaces. In an Altair help article, it is explained, “Implicit surfaces are perhaps best thought of as a field rather than a surface—at every point in space the field defines a scalar value, often some notional or actual distance to the nearest point on the surface. So, if we define the implicit surface as passing through all points in the field where the scalar values equal, say, zero, we call this surface the zero level-set of the field. The zero level-set can be computed and rendered as a single isosurface, which completely removes the need to compute and manage all of the watertight intersections that were present when stitching NURBS patches together.”

As should be clear, since implicit modeling is field driven, options for lattices are much vaster than those made with shape-driven models like BREP. In addition, implicit modeling is ideal for hardware acceleration on the GPU because with it, it is possible to run instant inside-outside checks due to all points on one side having positive scalar values while points on the other will have negative.

Beyond faster compute times, implicit modeling is also why Altair Inspire is so well suited to surface lattices. Typically made of TPMS, as mentioned above, it can be hard to reproduce them with parametric surfaces like NURBS. Furthermore, with implicit modeling, lattices are not created by copying and translating a unit cell in different directions, meaning that the number of unit cells can vary smoothly across the lattice structure as opposed to with traditional CAD.

Other benefits include the ability to layer gradient effects. This makes it possible to have lattices with decreases in relative density and unit cell size in different parts. Similarly, it is also possible to combine lattice design with morph operations to transition from one lattice unit cell to another. A boon for more complicated designs. You can find out more about Altair Inspire HERE and how to use it for lattices in 3D printing through TrueInsight HERE.

Which lattice would you use for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.