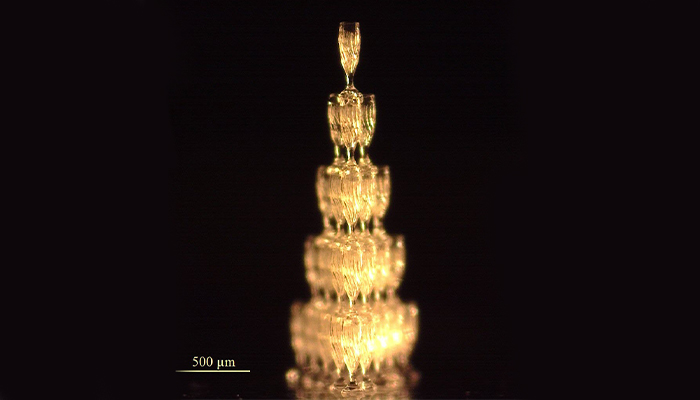

The smallest champagne pyramid ever 3D printed

Using its microfabrication 3D printing technology, Microlight3D created a 2-millimeter high champagne pyramid, consisting of 35 micro glasses. The French company has a great deal of experience in microprinting; with this creation it has managed to design the smallest pyramid of champagne in the world. Philippe Paliard, co-founder of Microlight3D, explains: “Since each flute is 0.4 millimeters high and contains 1 nanoliter of real Champion Ouy champagne, a normal bottle of champagne could fill 750 million of these flutes.“

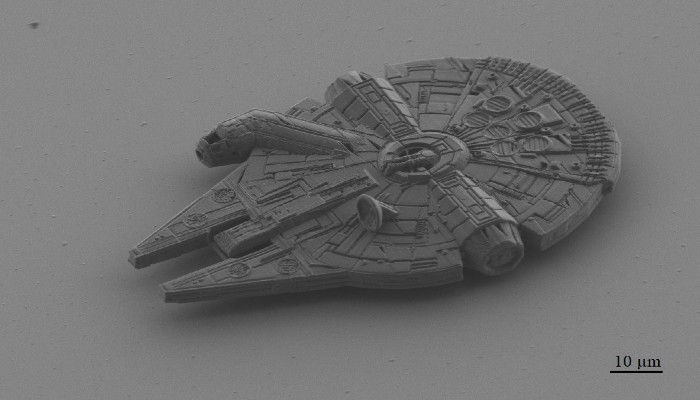

As its name suggests, microfabrication creates miniature parts, at the micrometer scale or even below, at the nanometer scale. Expert in this field, Microlight3D also attracted attention when its technology was used to 3D print miniatures from the Star Wars universe (0.01mm long) last year. These micro designs were created using the µFAB-3D machine, an ultra-high-resolution 3D printing system using technology called multiphoton lithography (MPL), more widely known as two-photon polymerization (2PP). This process makes it possible to create solid, miniature structures from photopolymerizable materials.

Star Wars figure measuring 0.1 millimeter long designed with the µFAB-3D printer | Photo Credits: Microlight3D

A millimetre-sized design

These micro flutes are based on OrmoGreen; a polymer filled with nanoparticles, which offers mechanical and thermal properties far superior to those of normal polymers. Mr. Paliard explains: “It is a material developed by Microlight3D. This polymer is filled with silica particles, the essential component of glass. This gives this material properties close to those of glass in terms of rigidity, transparency or thermal resistance. It was therefore the best material to make the champagne flutes!” But while Microlight3D did not need any outside help to design the flutes, the company did use a third party to fill the champagne glasses. “The very precise deposit of champagne in the flutes is the result of a collaboration between Microlight3D and Pierre-Luc Piveteau, a researcher at the Swiss Federal Institute of Technology in Lausanne.”

With this achievement, Microlight3D is showcasing its technology and the latest advances in microprinting in a fun and accessible way. “It is also a way to present a new functionality that will appear on our machines and that allows us to make high structures. He adds: “It can seem ridiculous but before today our systems could not make structures more than one millimeter high“. Before concluding: “A new development will make it possible to make objects up to 10 mm high. We will announce this new development in the next few weeks.” This is just the beginning it seems! You can find more information HERE.

The pyramid of flutes | Photo Credits: Microlight3D

What do you think of Microlight3D’s flutes of champagne? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!