What Are the Major Post-Processing Challenges in 2021?

Post-processing solutions manufacturer PostProcess Technologies has released the third edition of its Annual Additive Post-Printing Survey: Trends Report 2021. This year’s report confirms what was already announced last year, namely the desire to shorten this time-consuming step, to improve the quality of finished parts and to allow operators to focus on higher value-added tasks. Overall, users of additive manufacturing want to automate the various post-processing steps as much as possible, especially when it comes to mass production.

This year, the number of participants in the study doubled, demonstrating the growing interest in additive manufacturing among users. Another 50% of respondents are fully aware of the methods used in their companies, a new sign of interest. The PostProcess Technologies study focuses on post-processing trends according to the 3D printing processes chosen by the participating companies; not surprisingly, fused deposition modeling (FDM), photopolymerization and selective laser sintering (SLS) are among the top three, followed by MultiJet Fusion and material jetting. Each process has its own specific constraints, of course – something to keep in mind throughout this study.

Post-processing techniques depend on the technology used and the final application (photo credits: Nikko Industries)

Current Post-Processing Techniques

As there are many additive manufacturing processes, so too are there post-processing methods: removal of supports, excess materials, surface finishing, polishing, heat treatment, etc. Depending on the final application of the 3D printed part and the process used, the post-processing will be more or less long and complicated. And this year, the most used methods are similar to the previous years: printing support removal for 82% of the participants, surface finishing for 67%, resin removal for 45% and powder removal for 44%. These results are hardly surprising when you consider the 3D printing technologies most commonly used today.

PostProcessing zooms in on HP’s MultiJet Fusion process, which is becoming increasingly popular for mass production. Participants say that post-processing is a real challenge to move into mass production, and less than 18% of technology users think that currently available solutions are sufficient. This is an interesting point because additive manufacturing has moved from rapid prototyping to mass production, with players trying to facilitate this transition. As the study notes, the market is not quite ready, even if there are more initiatives. Moreover, on HP’s side, in 2021 the manufacturer has worked on developing more automated post-processing solutions, following this very logic of production. It is probably a challenge that will be met in a few years time.

Post-Processing Challenges in 2021

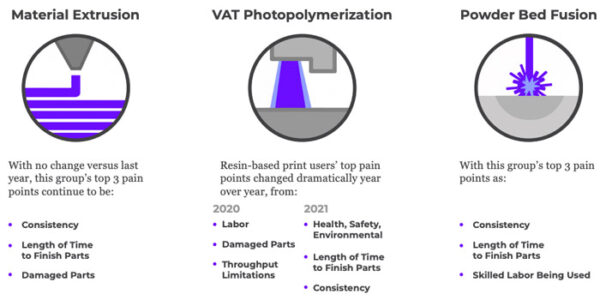

The 2021 edition highlights challenges faced by users that are quite similar to previous years. For 53% of survey participants, post-processing cycle time is too long, regardless of whether they are using FDM, SLA or SLS and 52% say it is very difficult to achieve consistent finished parts. Finally, the availability of skilled labor is a hindrance in post-processing operations. The additive manufacturing market needs people with skills and experience in these areas that are still sorely lacking.

The biggest post-processing challenges in 2021 according to the most used processes (photo credits: PostProcess Technologies)

The study also notes that for those who remove powder – whether in SLS or MJF – post-processing slows their manufacturing process and significantly increases their overall expenses. For resin removal, the most significant challenge involves safety, hygiene and waste management issues.

What is in Store in Post-Processing’s Future?

The results may seem rather pessimistic, but the willingness of participants to invest more in post-processing solutions must be emphasized. 30% claim to spend more than a quarter of their additive manufacturing budget on post-processing. Automotive companies are the ones for whom this investment is the most important. But what do participants want to invest in? For 76%, it’s to achieve better finished part quality, while for 45% of participants, it’s to reduce cycle time.

Looking ahead, it is interesting to note that 60% of companies surveyed want to improve health, safety and sustainability issues in their post-processing steps. This issue concerns the entire value chain of additive manufacturing and it is a point that will have to be studied closely in the coming years. You can find the whole study of PostProcess Technologies HERE.

*Cover Photo Credits: Hubs

What do you think of the indentified post-processing trends and challenges for 2021? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! And don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.