3D Print ceramic pieces on your SLA 3D printer

Six years ago, the American manufacturer Formlabs unveiled their first stereolithography 3D printer that was made to be accessible to as many people as possible, with a relatively low marketing price. Since then, the company has grown quickly, evolving their product range of 3D printers and materials while also successfully completing several fundraisers.A few days ago, they announced their official launch of an experimental Ceramic Resin for their European and North American users.

3D ceramic printing is of interest to an increasing amount of players in the additive manufacturing market; such as Kwambio who announced the arrival of a new industrial machine or the Israeli XJet with their Carmel range. The technology, however, is not accessible to all, with high prices and some complexity in its handling. Formlabs wants to lower this price, justifying the launch of Ceramic Resin, a material compatible with the Form 2 3D printer, which remains relatively accessible.

While they have proposed more colors for their resins that are compatible with their SLA 3D printers last year, they are looking this time to a ceramic solution, offering more opportunities to engineers and designers. It seems that the R&D and in-house production laboratories are becoming more and more interested in ceramic 3D printing. For example, the military uses ceramic materials to design lightweight shields, while electronics manufacturers use alumina ceramics for insulators, resistors, and semiconductors because of their high properties of heat and electrical conductivity.

The printing material Ceramic Resin

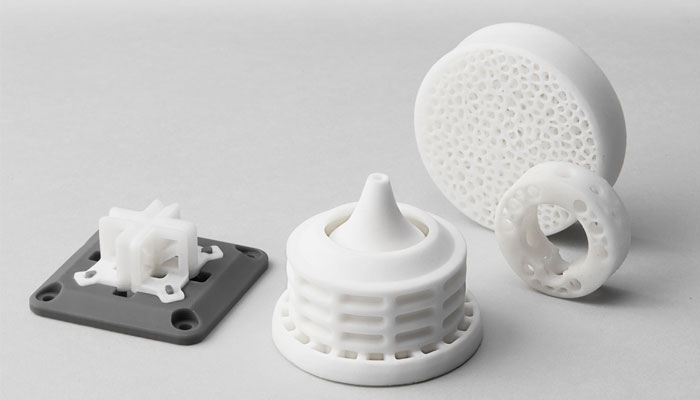

The new Ceramic Resin is a silica-filled photopolymer. Before being cooked, the pieces printed with this material have a porcelain-like finish; the cooking would burn all the photopolymer away and thus obtain a completely ceramic part that can be varnished. It has a high thermal resistance (up to 1000° C) and can withstand wear and corrosion. Be careful though, as the material would be a little more complex to handle depending on the manufacturer in comparison to their entire range of resins. They recommend doing several tests and experiments before printing the desired part.

Formlabs explains that they worked a lot with the generative design studio, Nervous System, to test the new material over a period of a few months. The studio has taken the opportunity to launch their first collection of 3D printed ceramic jewelry, Porifera. They wanted to combine 3D printing and ceramics to create complex geometric shapes while offering high quality. Their co-founder Jessica Rosenkrantz explains: “Ceramic materials are really beautiful and have nice qualities. They’re inexpensive and strong, and they have this nice tactile feel; they can be glossy or more earthy.” Nervous System has created very intricate parts that could not have been designed using traditional methods, particularly because of their fragility.

Find more information on the Ceramic Resin and all the stages of printing on the Formlabs website. More details are also available in the video below:

What do you think of the new Ceramic Resin material from Formlabs? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!