Ceramic Additive Manufacturing, a Growing Niche Market

The research firm IDTechEx has published a new report on the ceramic additive manufacturing market: it is expected to be worth $400 million by 2032, a seven-fold increase which is being driven by more and more players banking on this technology. The study looks at the main applications of ceramic 3D printing, material and machine manufacturers, as well as the sectors of activity that use this process the most, among other topics. Notably, the 10-year forecasts show that ceramic additive manufacturing has a bright future ahead of it, even if it remains an often unknown and still young technology.

Compared to polymer 3D printing or metal processes, ceramic additive manufacturing is less popular and more used for research and prototyping purposes. In fact, the main reason that it is used today is because it allows the creation of tools and parts that are simultaneously much less expensive and more complex. Hot isostatic pressing, extrusion and injection molding techniques have long been used in the ceramics industry, but the associated costs remain high and the lead times long. This is where additive manufacturing comes in, just like with the metal and polymer markets.

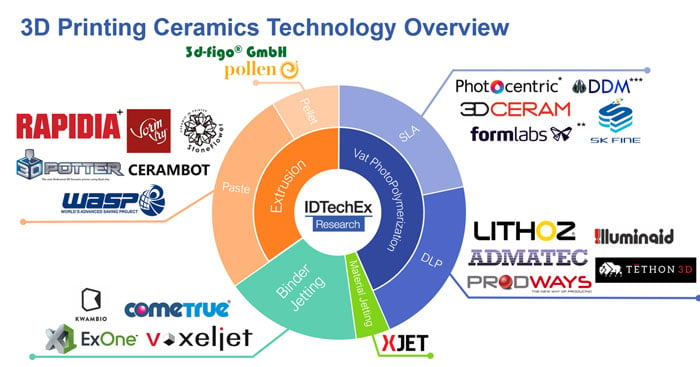

Manufacturers of ceramic 3D printing solutions (photo credits: IDTechEx)

The 3D Printing Ceramics 2022-2032: Technology and Market Outlook study focuses on the market players in the industry. For example, considering questions who are the machine manufacturers, the material manufacturers, the software manufacturers, but also the end users? It also looks at the existing processes – binder jetting, light curing, extrusion, etc. – that are used in 3D printing. Some players have specialized in this market since the beginning, such as Lithoz and 3D Ceram, and others have adapted their machines to make them compatible with ceramics. IDTechEx noted, “These companies’ interest in ceramic 3D printing indicates that the path for future growth for the market is open.”

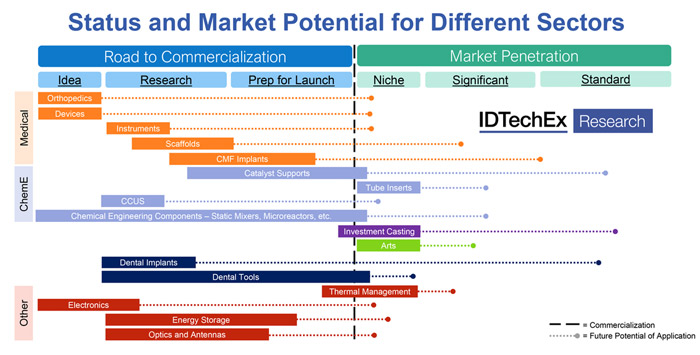

Finally, in terms of applications, the report shows that ceramic 3D printing processes are mainly used in R&D and for rapid prototyping applications. However, sectors such as aerospace, defense, dental and chemical engineering are also interested in the production of small series parts. As shown in the diagram below, there are many opportunities with a promising start to commercialization. The study highlights the room for growth in R&D sales, with a large number of research institutes and universities working to advance the technology in innovative applications (medical, energy storage, carbon capture, etc.).

Photo Credits: IDTechEx

One thing is certain: the market is growing, regardless of the sector. The next few years should be particularly interesting for the industry. If you would like to learn more you can find the report HERE.

*Thumbnail Photo Credits: Formlabs

Do you use ceramic 3D printing? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!