Could Cellulose Fibers Be Used As Reinforcement Material for Composite 3D Printing?

The German Institute of Textile and Fiber Research recently launched a research project to develop an innovative 3D printing method for composite materials. The goal is to produce components reinforced with bio-based and sustainable fibers such as cellulose fibers. The project team has collaborated with machine manufacturer Arburg to develop a print head that can extrude continuous cellulose fibers embedded in a cellulose-based matrix. The project, funded by Germany’s Federal Ministry of Education and Research, would make it possible to draw on a material that is very abundant today and design more durable parts that take full advantage of composite 3D printing.

The research project is an example of how we can take inspiration from nature and combine it with additive manufacturing. In our case, we are talking about additive manufacturing with composites. Without perhaps knowing it, we are surrounded by composites: Wood, plants, spider silk, or even skin. These natural fibers offer very interesting properties, whether in terms of strength or even lightness. So why not use them for 3D printing?

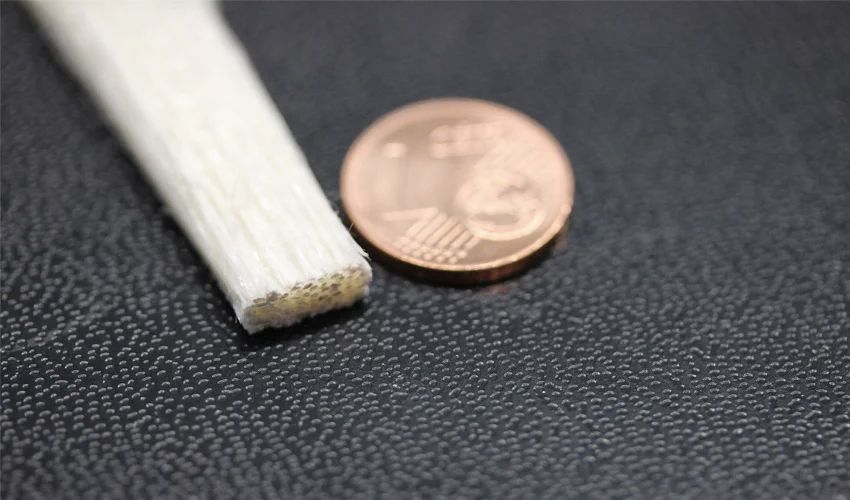

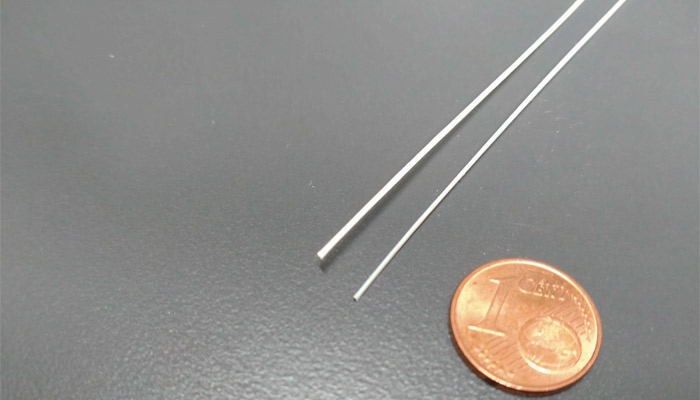

Cellulose fibers produced by pultrusion ( a portmanteau of pull and extrusion; as opposed to extrusion, which pushes the material, pultrusion pulls the material)

The biggest challenge is temperature management. This is because natural fibers – such as cellulose fibers – are very sensitive to high temperatures, which precludes the possibility of working with a PLA- or ABS-type plastic matrix, since the thermoplastic must be heated sufficiently to be applied layer by layer. So the team had to think of both a new matrix and a 3D printing process with the cellulose that would meet those temperature constraints.

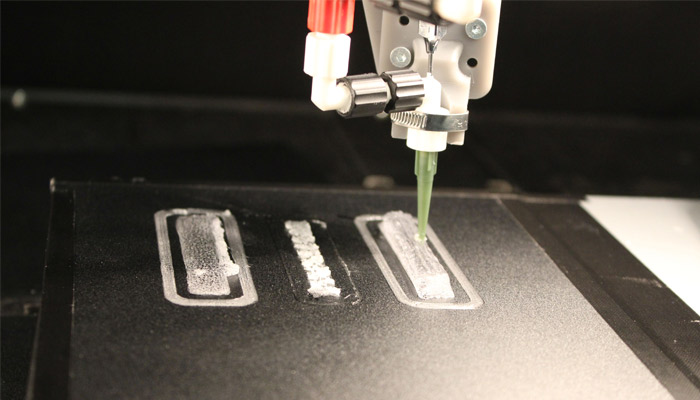

So it envisioned a cellulose-based matrix solution. The official press release provides the following explanation: “The cellulose fiber strand is first stabilized with a binder to be processed in the printer. The specially developed print head converts the binder into a matrix with which the continuous cellulose fibers are coated. Since the cellulose fibers and the matrix have similar chemical structures, the composite component is particularly stable.” Using a topological optimization solution, the team was also able to decide exactly where to place the continuous fibers, i.e. in the right direction in relation to the load applied to each part.

The developed 3D printing process

The mechanical properties, such as fracture strength, are exceptionally good. The solution-based and energy-saving manufacturing method developed by the research team can also be used in other processes for producing composite materials. It is particularly suitable for processing temperature-sensitive materials that are in high demand, such as natural or cellulose fibers.

Looking at the results obtained, the parts seem to have a very good breaking strength. This method of composite 3D printing could be especially interesting for working with more temperature-sensitive materials and would not be limited to natural fibers. More information can be found HERE.

What do you think about the use of cellulose in 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photos credit: DTF

It was very useful, thank you! I just got started with it, but I’m learning more about it every day! Thank you and keep doing fantastic!