Cartesian vs. Core XY, Delta & Polar: Comparing FDM Motion Systems

3D printers can produce a wide range of three-dimensional objects using various materials. Depending on the technology, this may involve curing a liquid resin with a light source (SLA, DLP, LCD) or sintering powdered material (SLS, LPBF). In extrusion-based processes, the material, in the form of filament or pellets, is melted and deposited layer by layer onto a build platform through a heated nozzle. But how exactly does the filament travel to its destination?

Well, there are several options. With commercially available 3D printers, this is referred to as motion systems. These motion systems determine how the print head or build platform moves in space and in all directions so that the print layers can be applied one after the other. In this article, we will look at the most common FDM printer motions, explain how they work and what their differences are. You will also find out why some motion systems are particularly popular and what advantages they offer.

The motion system of a 3D printer – also known as kinematics – defines how the material is deposited. It influences the components that move and the directions in which they move. As a rule, the material is applied to the build plate either by the extruder moving in the various axes or by the print bed itself. The motion system is crucial for positioning (for accurate and repeatable application of the material), printing speed and mechanical stability. Summarizing these parameters, the motion system plays a decisive role in the print quality.

Although the task of the different kinematic systems is the same, there are different ways in which these systems can be structured. On the one hand, there are Cartesian variants (including bedslinger) and their derivatives CoreXY and H-Bot. On the other hand, there are delta and polar systems. Robotic arms can also be considered as motion systems, as is the case with SCARA systems. To keep things simple, we will stick to the basic versions and compare Cartesian systems, CoreXY, Delta and Polar systems.

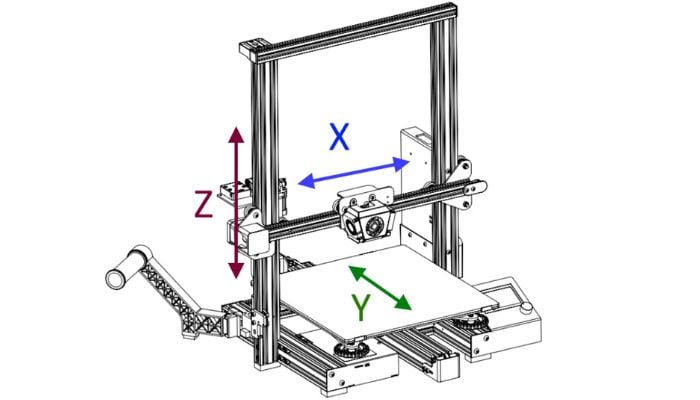

The three axes by a coordinate system. (Image: Creality)

How Do Different Motion Systems Work?

You are probably familiar with some models from the manufacturers Prusa, Creality and UltiMaker. All of these manufacturers are among the pioneers of FDM printers for end users. What they have in common is that they have a similar design and often have Cartesian drive systems. Cartesian means that the axes are arranged according to a coordinate system and are moved independently of each other by their own motor. The motor of axis X moves it, only then does the motor of axis Y intervene to move it, and so on. If it is a “bedslinger,” the build plate moves along the Y axis, the tool head along the X and Z directions. We find this design in the Prusa i3 MK3, for example, which is why this Cartesian motion system is also called “i3 style.” Creality also integrates this motion system into its Ender series.

However, it is also possible that the print bed only moves vertically, i.e. on the Z-axis. In this case, the tool head moves in the X and Y directions. UltiMaker implements this concept, whereby the printers often have a typical box shape, which gives this system the name “quadrap/UltiMaker style/box style.”

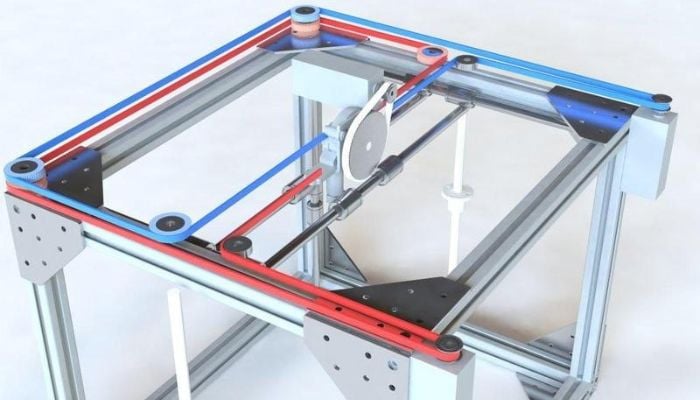

The Cartesian system (especially in UltiMaker or box style) should not be confused with the CoreXY motion system. With CoreXY printers, the print head moves in the X and Y directions, while the print bed only moves in the Z direction. The special feature: The motors for X and Y work together – they pull on the belts together to move the print head exactly where it needs to go. CoreXY printers are driven by two long toothed belts mounted on the print head. This provides more mechanical stability and a significantly higher speed than Cartesian systems. Examples of CoreXY drive systems are the 3D printers from Voron or the Bambu Lab X1.

The motors in the X and Y directions pull on the belts together. (Image: Pinterest)

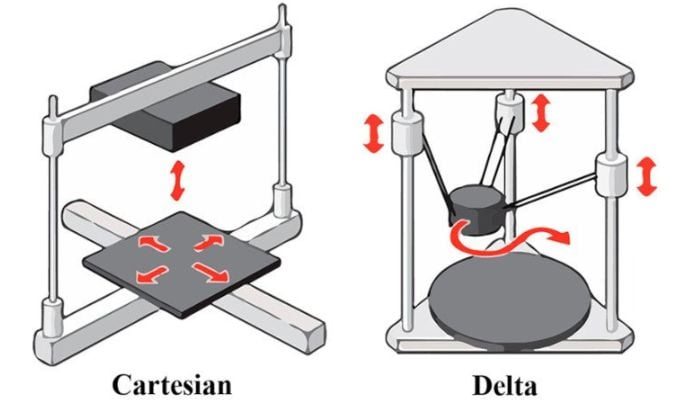

Delta 3D printers, on the other hand, are recognizable at first glance. The Delta design differs clearly from Cartesian or CoreXY systems. In contrast to these, the print bed in Delta models is completely rigid and round. This means that much less mass has to be moved, and the print head is driven by three motors, resulting in better stability and precision. The print head is attached to three Z-axes and is moved from there in all directions. Lifting the various Z-axes results in movement on the X- or Y-axis. This enables particularly good results to be achieved with round and tall objects.

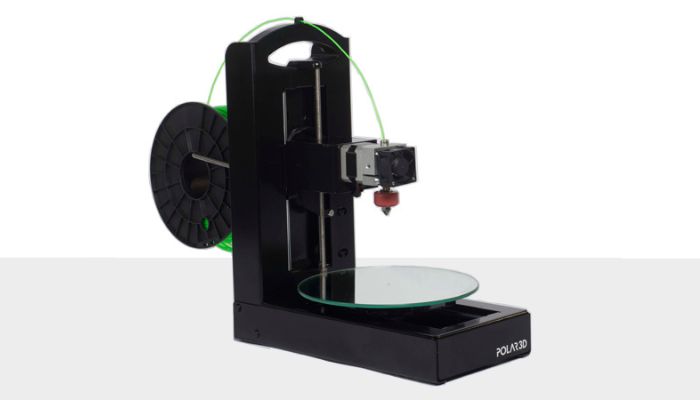

Polar Motion Systems are detached from Cartesian space. Although the Z-axis remains for up and down direction control, the Polar version has a rotating build plate and a radial arm that positions the print head. The print head is guided from the center outwards and back, so the movements are defined by radius and angle.

All motion systems offer advantages and limitations. Choosing the right motion system and, therefore, the right 3D printer depends heavily on what you want to achieve with your 3D prints.

Cartesian motion system and delta system in comparison. (Image: 3Dsourced)

Motion Systems in Detail: History, Popularity, User Experience, Price

The landscape of FDM motion systems has evolved significantly over the past decade, driven by technological innovation, user expectations and the constant pursuit of better speed, quality and reliability. Each system has its own advantages and disadvantages in terms of ease of use, performance and cost. The motion architecture not only influences the printing characteristics but also directly affects the price and complexity of a machine. So, let’s examine how the main motion systems have evolved, how they are used today and what you can expect in terms of user experience and price.

Bedsligner

Development and Popularity

Bedslinger-style Cartesian 3D printers were the early heroes of the hobbyist scene. Their simplicity and low barrier to entry made them ideal for hobbyists and educational environments. Machines like the Prusa Mendel and Creality Ender 3 laid the foundation for accessible 3D printing, and their design remains influential today. Due to their affordability, modularity and extensive community support, they remain the most common type in the consumer sector.

Bedslinger printers are generally the most affordable on the market. Entry-level models are available for as little as $175, while more sophisticated models are usually priced between $500 and $1000.

Popular bedslingers include the Prusa i3 MK4S, the Creality Ender 3 series and the Bambu Lab A1 Mini. (Image: Bambu Lab)

User Experience

These printers are easy to operate, maintain and modify. Their open design makes all components easily accessible and the mechanical setup is intuitive. Print quality is generally solid for hobbyist use, although high-speed printing can experience glitches due to the moving bed. Bedslingers are nevertheless reliable workhorses with predictable behavior and an extensive ecosystem of support and upgrades.

Box-Style Cartesian 3D Printers

Development and Popularity

As FDM became established in professional and industrial environments, box-style Cartesian printers ushered in the next level of reliability and print consistency. With their fully enclosed structure and fixed print bed, these machines are optimized for engineering materials and demanding applications. They are widely used in professional, prosumer and educational environments where stability, security and consistency are paramount.

For a prosumer-grade box-style machine, expect to pay between $600 and $1,500, while professional models can cost more than $2,500 and up to $6,000 or more, depending on build volume and industrial features.

UltiMaker uses a box-style Cartesian motion system for all of its 3D printers. Notable examples of this are the models in the S series, such as the S8. Creality also uses this system for its Ender 5. (Image: Elliot Saldukaite, 3Dnatives)

User Experience

Cartesian 3D printers in box format offer excellent print quality and thermal consistency, especially with materials such as ABS or PC. They are relatively easy to use, and setup can be a little more involved, but ongoing use is often smooth. Maintenance requires more care as access to internal parts can be limited. In summary, they are ideal for users who prioritize precision and uptime over manual adjustments.

CoreXY / H-Bot

Development and Popularity

CoreXY motion systems gained prominence as the 3D printing community began to demand faster speeds and higher print quality. By keeping the motors stationary and minimizing the moving mass, CoreXY systems achieve high acceleration and excellent surface accuracy. They were used early on in open source projects such as Voron and later became mainstream through commercial successes such as the Bambu Lab X1 series. CoreXY is now considered the motion system of choice for users seeking high performance without fully venturing into industrial territory.

CoreXY printers cover a broad spectrum. DIY kits cost between $500 and $1,600, depending on the quality of the components, while turnkey machines start at around $750 and can cost up to $1,500 or more.

Core XY (left) and H-Bot (right) 3D printers are becoming increasingly popular thanks to their compact size and ability to work accurately at high speeds. (Image: Elliot Saldukaite, 3Dnatives)

User Experience

Performance is excellent, but setup can be daunting, especially with DIY kits like the Voron 2.4, where belt adjustment, alignment and frame rigidity are critical. Once properly configured, these machines offer a premium printing experience with high throughput and fine detail. Maintenance is more involved, but is often required less frequently with a good initial setup. With commercial models such as the Bambu X1, the user experience is optimized and can compete with consumer plug-and-play machines.

Delta

Development and Popularity

Delta printers, with their three-tower geometry and elegant motion, initially promised speed and visual appeal. In theory, they offer fast, fluid motion with fewer moving parts. However, the complexity of motion planning, calibration issues, and declining precision at the edges of the build plate limited their popularity. Today, they are mainly found in niche enthusiast circles or among users seeking a large build volume at a reasonable price.

Despite their complexity, delta printers are relatively affordable, with prices ranging from $300 to $800 for most models, providing an accessible entry point for users curious about this unique motion architecture. More advanced solutions can cost up to $10,000.

Not many printers use delta kinematics, but Anycubic and FLSun have both launched printers with this technology in the past, and some more advanced solutions are also available, such as the Prusa Pro HT90 and printers from WASP. (Image: FLSUN)

User Experience

Delta printers are often more difficult to calibrate because all three belts and arms must be adjusted equally for optimal results. While they are visually appealing and fast, print errors are more significant than with Cartesian or CoreXY systems. Maintenance and upgrades are more complex, especially with firmware and automatic bed leveling systems.

Polar

Development and Popularity

Polar motion systems use a rotating print bed and a radial arm, allowing motion to be achieved via polar coordinates rather than linear X/Y motion. These printers attracted early attention thanks to their compact design, but struggled with software compatibility and performance reliability. Today, Polar printers have largely disappeared from the market or are used only for educational and research projects.

During their brief availability, devices like the Polar3D ranged in price from $400 to $700. However, these are now largely discontinued, reflecting their niche and experimental nature within the broader FDM ecosystem. Polar printers can be built from scratch, starting at around $300, with the price depending heavily on the components selected for the build.

Polar3D used to sell Polar 3D printers, but today there are no commercially available solutions, although Polar printers continue to exist as DIY kits and personal projects like Joshua Bird’s “core-RΘ.” (Image: Polar3D)

User Experience

These machines are difficult to operate due to their unusual motion patterns, lack of compatibility with slicers, and unusual mechanics. Precision is generally poor for rectangular or non-circular models, and software support is minimal. Maintenance is also hampered by the lack of standard parts. Polar printers should be viewed more as experimental gadgets than reliable production machines.

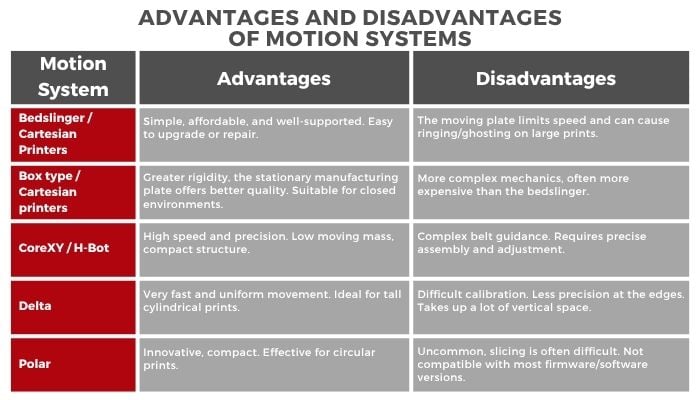

In conclusion, each FDM motion system has strengths and disadvantages. Their suitability depends largely on the specific application. Bedslingers remain the simplest and most cost-effective, while Cartesian box-style printers offer a more compact design. CoreXY delivers power and speed but requires precision during setup. Delta 3D printers offer aesthetics and height, but are complex. And Polar-style printers, while innovative, are best used for experimental or educational purposes. To summarize this comparison and provide a quick overview of the different motion systems, we have created a clear table:

Credit: 3Dnatives

Which of these motion systems do you use? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.