CADvision and ETEC Talk About How Additive Has Become a Must-Have Tool and How They Are Advancing Industrial Polymer 3D Printing

As additive manufacturing continues to industrialize and advance, partnerships and collaborations become ever more important. Take the case of CADvision and ETEC, part of Desktop Metal. The two have worked and grown together for nearly seven years and are committed to helping to advance polymer additive manufacturing for industrial applications.

We spoke to the CEO of CADvision and the Head of Polymers in EMEA at Desktop Metal, to learn more about the partnership between the companies and how they are promoting and accelerating DLP 3D printing in Europe.

Manuel Delgado (left) and Julien Markarian (right)

3DN: Tell us a little about yourself and your connection to 3D printing?

JM: I am Julien Markarian, the CEO of CADvision. CADvision is a distributer located in France that has developed its skills in the integration of additive manufacturing in the industrial, education/research and medical sectors over the last 25 years.

MD: I am Manuel Delgado, RSM and Head of Polymers in EMEA at Desktop Metal. I have nine years of experience of in additive manufacturing in the polymer industry covering different materials, equipment technologies and holding various leadership positions.

3DN: What are the capabilities of ETEC’s industrial polymer machines? What kind of applications can you have for customers?

JM: ETEC polymer machines are the most advanced available on the market. Thanks to industrial partnerships, ETEC machines are compatible with very advanced material that can be used on platforms that offer high scalability and repeatability. ETEC is currently the only company that can offer systems that are really built for production, with great build volumes and high accuracy.

Different solutions from ETEC used by CADvision at their facility in Valence

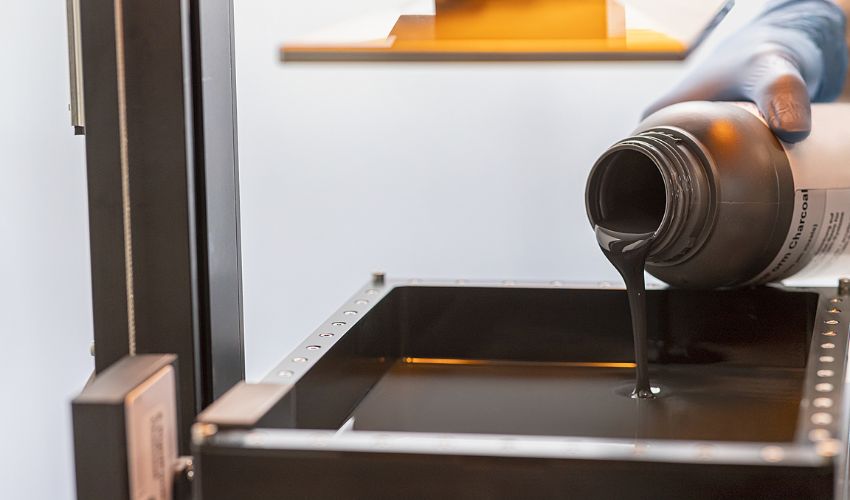

ETEC polymer machines have key differentiators against any other player on the polymer market. Among those, the variety of industrial-compatible resins and the quality of their management, and the growing capacity of the systems (for example with the latest Xtreme 8K, which offers an unprecedented build volume) are opening for real vast applications in all industrial markets.

3DN: What role does material selection play? What are the benefits of using ETEC for CADvision?

JM: Material selection is key for making additive manufacturing successful, especially for DLP. CADvision’s role, as integrator for its customers, is, among other things, to educate on this selection, and keep up to date on alternatives and benefits of using this or that material. ETEC is by far the most open technology for materials, and the portfolio is constantly enlarging.

MD: Material capabilities are a decisive factor in the enablement of any given application. ETEC has optimised its offering by adding top-class industrial materials to its portfolio, cooperating with the world’s best material suppliers and growing our own material development capabilities, developing unique breakthrough solutions such as FreeFoam®, the first true 3D printable foam.

Through ETEC and its solutions and materials, it is possible for CADvision to make parts that are suitable for industrial applications

3DN: Could you tell us more about ETEC and CADvision?

JM: CADvision’s mission is to assist its customers in the setup of additive manufacturing as a tool for improving the production flexibility. Additive manufacturing is becoming a must-have on top of more traditional approaches as it allows shortcuts and novel design in more and more projects or existing productions.

AM adoption requires very highly skilled assistance to get acceleration, potential users not always being aware of all the potential of it to make it viable in their factories. identification and ROI estimation on each potential project is key, and it is probably what slows down adoption. Being supported by a qualified partner is therefore the key to success.

MD: Founded in 2002, ETEC is a world leader in polymer 3D Printing technology and original creator of the world’s first DLP printer. Our mission is to make 3D printing of end-use polymer parts accessible at scale to all engineers, designers and manufacturers using cost-competitive, high-speed and exceptional-quality 3D printing.

Parts on the Xtreme 8K 3D printer

3DN: How long have you had this partnership? What have been the benefits?

JM: The DM/CADvision partnership started in 2017 with DM metal solutions. Fast adoption of the first released system (Studio) allowed CADvision to acquire strong experience in this new growing market. CADvision then enjoyed the successive acquisitions made by the group, including EnvisionTEC which was the foundation for the new ETEC line.

CADvision chose ETEC and Desktop Metal as one of its main partners because they are at the leading edge of additive manufacturing systems in a large field of applications. Before the last decade, CADvision was mainly focusing on distributing 3D printers for the prototyping applications in R&D centers. The partnership with Desktop Metal was key to switching from this small potential market to the real additive manufacturing market, which is much larger, though harder to master.

3DN: Why DLP? What are the advantages or difficulties of using DLP compared to other AM processes?

The Pro XL from ETEC

JM: DLP is the ideal technology for opening large opportunities in additive manufacturing for resin-based parts that are compatible with industrial applications. DLP is a very complementary approach to plastic deposition as it brings different materials and allows for high-quality parts compatible with industrial use.

MD: DLP offers a unique set of advantages in the polymer 3D printing world: surface quality, high feature details and repeatability, but as a unique feature of DLP: high throughput and scalability compared to other polymer technologies. As a downside, like other resin-based technologies, it requires a post processing workflow, which is right now in a quick process of modernisation with automatic and semi-automatic solutions

3DN: Any last words for the reader?

JM: Choosing ETEC/Desktop Metal and CADvision is a guarantee for the customers to make the additive manufacturing integration successful, and by consequence see its use progress in the company wherever it makes sense. You can learn more about us HERE.

DM: ETEC currently offers the most comprehensive equipment solutions and material offering for the industrial user. In addition to that, we have recently announced our Co-Location Production & Knowledge Transfer, enabling users worldwide to successfully adopt DLP technologies at scale, working hand in hand with our team of experts at our facilities. You can learn more about ETEC HERE.

What do you think of the partnership between CADvision and ETEC? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.