How the Breton Genesi Ecosystem Is Transforming Industries Through Large Additive Manufacturing Combined with AI

When thinking about the benefits of additive manufacturing, some of the most cited are the ability to create complex geometries, produce prototypes in a short amount of time and customize production batches. However, that does not mean there are not still issues with additive technologies. Something that is especially clear once AM is scaled up.

When it comes to large-format additive manufacturing (LFAM) or large additive manufacturing (LAM), large-scale industrial adoption is still challenging, notably due to difficulties with precise management of the extrusion process. What does this mean? Well, the stability of parameters such as speed, extrusion rate and temperature is fundamental to ensuring reliable results. However, market solutions can overlook the fluid dynamics and thermal management of the deposited material, instead leaving these choices to the operator. Furthermore, preparing models for LAM can be complex and require intense research. This is where Breton comes in.

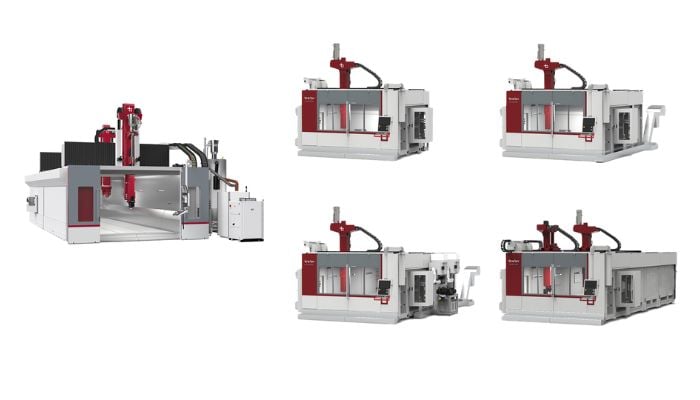

The Breton Genesi line

The company is aiming to transform thermoplastic LAM to help users to unlock its true potential, allowing them to truly benefit from advantages like reduced printing times and costs due to the printing of large volumes of material. As such, drawing on its extensive experience in extrusion technologies, Breton has developed a new range of large 3D printers, named Genesi. But what exactly sets them apart?

A Closer Look at the Breton Genesi range

As mentioned, the Breton Genesi product range is dedicated to Large Additive Manufacturing (LAM) with thermoplastics. Moreover, the range has been designed to be a true ecosystem, integrating machine learning algorithms and advanced AI to help optimize AM processes. The company’s goal? To help others to transform their business models through 3D printing.

Indeed, what sets the Breton Genesi range apart is undoubtedly its focus on predictive manufacturing. More specifically, the process is based on machine learning, providing predefined printing parameters and allowing customers to characterize new materials in collaboration with Breton. The solution is then able to automatically adapt different variables to ensure optimal printing.

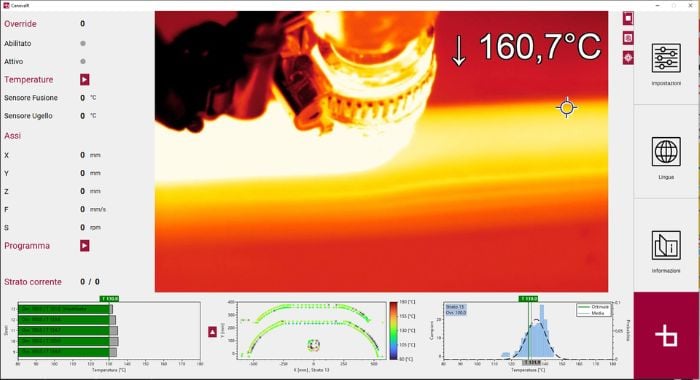

Breton CANOVA software

Additionally, during printing, a “reinforced learning” system monitors the process and adjusts subsequent layers to maintain consistent fusion. AI is then used to process data from each printing to continuously improve predictive algorithms. More specifically, the Breton CANOVA post-processing software manages the extruder parameters through an exclusive AI algorithm, simplifying the operator’s work and guaranteeing repeatable results based on previous tests: users just need to select printer model and the material from the database.

Breton Genesi is available in “Pure Additive” and hybrid versions, with the latter integrating high-speed milling. The stroke configuration is customizable. The hybrid version allows the obtention of “ready to use” parts by combining “near net shape” printing with finishing via milling. And to ensure process quality, each Breton Genesi 3D printer is equipped with a heated build plate and uses thermal cameras to control the adhesion temperature of the layers. This comprehensive control system contributes significantly to the reliability of the 3D printer.

The Breton Genesi boasts a comprehensive control system

In terms of materials, all the solutions in the Breton Genesi range are compatible with polymers and composites, making them suitable for sectors like aerospace, maritime, automotive, mold & die, energy and general engineering. The maximum extrusion capacity of the Breton Genesi E1 and E2 models is 90 kg/h, while the larger E3/E4 models can reach up to 200 kg of material per hour, with a maximum part height of 2.5 meters. Breton Genesi 3D printers are supplied with a Siemens Sinumerik One numerical control, and installation times for the E1/E2 variants are only five days.

Superior Sustainability and Material Efficiency for Different Industries

Predictive manufacturing in the Breton Genesi solutions has another benefit. The effectiveness of the technology allows users to save up to 60% of material during printing. This not only saves costs but also improves sustainability.

This can be seen through a variety of applications. For example, Northern Light Composites, a startup in the field of sustainable composite materials for pleasure boating, turned to the Breton Genesi to create molds for the prototype of the EcoFoiler, the world’s first fully recycled foiling hull. The collaboration allowed for high standards of precision and quality while making the hull with advanced thermoplastic materials.

Another case is Kis, the fully 3D printed kitchen island, the result of a successful collaboration among partners using an open innovation approach. Using recycled materials and a predictive control system based on artificial intelligence, Breton Genesi reduces waste and energy consumption, ensuring efficient and environmentally friendly production.

Gabriele Corletto, Business Development Manager of Breton confirmed “Large format 3D printing enables the rapid production of prototypes or fully customized objects without significant upfront investment. In some industries, the time and cost benefits are already evident, such as aerospace, automotive and marine. Others still need to be explored and require innovative companies willing to take on the challenge.

Parts made with the Breton Genesi

It should be noted as well, that beyond selling machines, Breton also offers a 3D printing service, making its machines and expertise available to companies who want to try AM, become a Breton Authorized Additive Manufacturing Center or need to 3D print any large-scale pieces in thermoplastic material.

What do you think of the Breton Genesi 3D printers and their applications? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.