Bosch Advanced Ceramics on Industry Hurdles, Additive Solutions and the Future of Ceramic Additive Manufacturing

As the industrial additive manufacturing (AM) landscape continues to grow and evolve, one of the biggest revelations in recent years has been ceramic additive manufacturing. Technical ceramics offer unparalleled properties, from extreme heat resistance to exceptional corrosion protection. When combined with the design flexibility and precision of additive technologies, this material is becoming a true game-changer for industries ranging from medical and aerospace to semiconductors and beyond.

We spoke with Malte Hartmann, Development Engineer at Bosch Advanced Ceramics (BAC), part of the Bosch Group. BAC is a contract manufacturer specialized in industrial ceramic AM with a clear mission: to make the technology a benchmark for scalable, series production and high-performance applications. But what projects is BAC working on? What challenges do their customers face, and how can AM provide the answer? Don’t miss the full interview!

3DN: Can you introduce yourself and your connection to 3D printing?

Malte Hartmann

My name is Malte Hartmann. I have been operating in the field of ceramic 3D printing for about 10 years now. My educational background is in chemistry and materials technology. I first encountered additive manufacturing (AM) at the research group of Prof. Jürgen Stampfl of the Vienna University of Technology, who later became my doctorate supervisor. My dissertation focused on the chemical and technological optimization of lithography-based additive manufacturing for dental ceramics. After a brief post-doctoral period at the Friedrich-Alexander University Erlangen-Nuremberg, I made a deliberate transition to industry to pursue my goal of bringing ceramic AM to large-scale production.

3DN: What is the mission of Bosch Advanced Ceramics and your role in the company?

Many people regard 3D printing as a suitable tool to create prototypes, but we have the vision of bringing ceramic additive manufacturing to large-scale series. In this context we serve as a contract manufacturer, who focuses solely on AM. Seated in a Bosch production plant in the south of Bavaria with a long history of ceramic production by injection molding, we built on that profound knowledge to bring additive manufacturing from research to industrial production.

My role revolves around the scalability of additive manufacturing. Everyone who has worked with that technology knows that it’s not just “plug and play.” Before and after the printing itself, there are several steps to consider, e.g. print job preparation, cleaning off excess material and of course thermal processing. Streamlining the value chain, automating the process and finding scalable solutions are a few of my main tasks.

3DN: What additive manufacturing technologies and ceramic materials do you use?

From the start, we have been working exclusively with vat photopolymerization (VPP)-based processes. We are constantly scanning the market for upcoming alternatives, but up to now VPP best suits our requirements in terms of surface roughness, density, feature resolution and mechanical strength.

As the historic ceramic production in the Bosch Plant Blaichach was based on dense oxide ceramics, building on that expertise allowed us to quickly establish several materials of that group, e.g. alumina, zirconia, zirconia toughened alumina (ZTA) and alumina toughened zirconia (ATZ). Given the right business case, we are open to expanding that portfolio.

3DN: Are clients mainly seeking serial production or prototyping? How is demand evolving?

Demand for ceramic AM is steadily increasing, driven by our strategic focus on series production for our customers. While every project naturally commences with a prototyping phase, our objective is always to transition these prototypes into qualified series production – encompassing both smaller and larger volumes. We have deliberately shifted our focus from using AM as an internal prototyping tool for ceramic injection molding to directly addressing our clients’ AM serial production needs. This approach leverages AM’s inherent flexibility as a tool-free production method, allowing us to seamlessly scale and adapt production once all parameters for a specific component are established.

3DN: What are the main challenges your clients face when they come to you?

The challenges of our customers are quite diverse. The majority typically approach us with two primary technical challenges. Firstly, they face limitations in material performance for their applications. This often manifests as a need for properties like higher temperature resistance, enhanced wear resistance or superior chemical inertness. Secondly, they require complex geometries or integrated functionalities that are simply unachievable through conventional manufacturing. This could involve highly intricate internal structures, lightweight designs or the consolidation of multiple components into a single part.

3DN: How do you help solve these problems?

Our approach begins with an in-depth technical consultation to precisely understand the client’s pain points and requirements. The earlier we are included in the design and thought process, the more efficient the cooperation and the better the result.

This initial phase is crucial, as it allows us to collaboratively refine designs for AM, optimizing for both performance and manufacturability. We then leverage our advanced VPP (Vat Photopolymerization) technology, which excels in producing parts with exceptional detail, accuracy and surface finish from a range of high-performance ceramic materials.

BAC helped a client to replace complex, multi-component assemblies – such as an electronic carrier plate with intricate channels – with a single 3D-printed ceramic part, achieving both enhanced performance and significant design simplification.

For the clients who lack familiarity with the full potential of ceramic AM, we engage in a collaborative process to identify and evaluate potential applications, often helping them discover entirely new pathways.

We support them with regards to ceramic AM’s capabilities through collaborative proof-of-concept projects, demonstrating the technology’s performance and reliability firsthand. If they have cost concerns, we guide them to consider the Total Cost of Ownership (TCO). While the upfront part cost might seem higher, the long-term benefits – such as extended lifespan, reduced weight or simplified assembly – often lead to significant overall savings and superior performance that conventional parts simply cannot deliver. Our commitment is to provide a comprehensive solution that not only meets their immediate technical needs but also offers a sustainable, value-driven pathway forward.

3DN: Can you share a challenging use case where ceramic AM enabled a breakthrough solution?

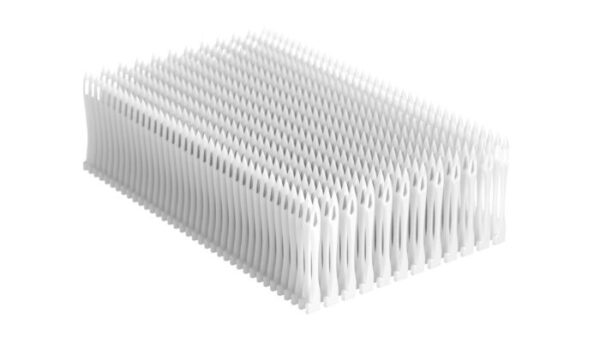

The textile industry traditionally uses many pieces made from technical ceramics. A use case which shows the transformative potential of ceramic AM is the production of precision ceramic needles for advanced textile manufacturing.

The challenge involved the need for highly wear-resistant, precise and geometrically complex components for Tailored Fiber Placement (TFP) processes, which involve the precise handling of abrasive fibers like glass or carbon. Conventional manufacturing methods struggled to achieve the required dimensional accuracy, surface quality and material properties simultaneously, especially at high volumes.

Our solution utilized ceramic AM to produce complex ceramic needles made from alumina (99.8% purity). One of the most significant breakthroughs here is the ability to efficiently produce these intricate parts in series. A single build platform allows for the simultaneous fabrication of 444 identical, complex needles. Each needle is approximately 22.3 mm long, with a precise eye that widens from 1 mm to 1.5 mm, and requires a tolerance of ±0.025 mm.

The application of alumina provided crucial material advantages. Their exceptionally high wear resistance ensures significantly extended tool life when processing abrasive fibers, reducing downtime and maintenance. Furthermore, the low density of ceramics contributes to a reduced component weight, enabling faster and more dynamic movements within the textile machinery without compromising stability. Coupled with their high rigidity, ceramic needles prevent deflection during operation, ensuring unparalleled precision in fiber placement.

This example highlights not only our capability in the series production of highly complex ceramic components but also how ceramic AM directly addresses critical performance bottlenecks in demanding industrial applications.

3DN: In your experience, which industries benefit the most from ceramic AM? What applications and materials stand out?

During my time at Bosch Advanced Ceramics, I have had hundreds of technical talks with customers from various kinds of industries. From my perspective, any industry that needs technical ceramics can potentially benefit from ceramic AM. This can be due to several reasons. AM can enable complex designs like no other production method and therefore increase efficiency of a certain product. Looking at assemblies, AM can produce single parts, which traditionally had to be produced individually. This reduces assembly costs. Especially industries with a “high diversity, low spread” product portfolio, like the medical sector, can strongly benefit, as tooling costs do not apply to AM.

Key industries that stand to gain the most from ceramic AM include semiconductors, medical devices, aerospace, chemical processing, renewable energy and high-performance industrial machinery. In semiconductors, ceramic AM allows for components with high purity, chemical resistance and electrical resistance for components like wafer chucks, gas showerheads or intricate fluidic manifolds.

In medical devices, AM supports biocompatible, sterilizable and ergonomically optimized parts. Ceramic AM also excels in fabricating miniaturized parts for diagnostic equipment or specialized tools.

If we look at aerospace applications, they benefit from lightweight, heat-resistant components, while sectors like chemical processing and energy leverage AM for corrosion and wear-resistant parts in extreme environments. Finally, industrial machinery and metrology gain access to custom, high-precision, long-lasting components.

Across all these sectors, the primary benefits of ceramic AM include enhanced design freedom, improved performance in demanding conditions and greater cost-efficiency through part consolidation and longer service life.

3DN: How do you see the future of ceramic additive manufacturing?

Many experts believe that AM will find its niche among established production technologies, but we believe that AM’s inherent connection to a digital workflow and the industry’s need for faster development cycles, will lead to a far more significant position of AM. Combining outstanding material properties with unmatched design freedom and digital agility makes it a cornerstone technology for future high performance applications, and we are excited to explore these possibilities.

3DN: Any last words for our readers?

I’m happy for anyone sharing their enthusiasm for this exciting technology and the possibilities it opens. The maker scene has always been a strong influence on the development of AM technology due to its vast creativity. Thank you for your effort and attention. To learn more about BAC, click HERE.

What od you think of industrial ceramic AM? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Bosch Advanced Ceramics