Bluecare, Fabulous’ New Powder Dedicated to the Food Sector

Since 2014, Fabulous, co-founded by the Coulet brothers, has been supporting French companies from a variety of industries in integrating additive manufacturing. In 2020, however, it undertook a strategic shift by initiating a new complementary activity of powder materials development for the 3D printing sector. Now, it is introducing BLUECARE, a new powder for the food sector.

With its experience in industrializing technology and following the company’s technical reinforcement, Fabulous now offers an initial range of materials that meet the sector’s new needs and that are compatible with industrial polymer powder bed technologies (LS, SLS, HSS, IRS). And according to co-founder Arnault Coulet, the company is bringing something new to the table: “Fabulous, an expert in 3D polymer materials and applfideications, is now bringing premium innovation to a market that is turning to production and is waiting for dedicated materials that meet their applications.”

The Fabulous team (photo credits: Fabulous)

BLUECARE, 1st material in the “Safety and Security” range

Whether in the Food, Defense or Health sectors, the demands for 3D printing materials are increasingly specific. The “Safety and Security” range was created to meet this promising market. For the time being, this new range, designed by Fabulous, is composed of three products and aims to provide powders that were previously unavailable on the market. With high added values and functionalities, and mainly intended for production, these materials offer very specific properties, applications and certifications.

Fabulous’ flagship material meets the requirements of international food industry regulations. Named BLUECARE, it is unique in the AM market as it holds to EU n° 10/2011 certifications. It can therefore be brought into contact with food and alcohol, and has mechanical and tribological properties that are particularly suited to this market. Fabulous’ co-founder explains: “BLUECARE is a unique powder material on the additive manufacturing market, which meets the functionalities and certifications specific to the food industry.

As its name indicates, this powder allows for mass production of blue colored plastic parts. As no food is blue, this choice is not insignificant and is one that would be well understood in the food industry: the blue color allows the optical identification of the presence or absence of plastic in food (foreign body detection). Like a food conveyor hinge or a suction nozzle on a bottling line, BLUECARE powder can be used to produce various applications in the food industry, including final parts in permanent contact with food.

BLUECARE is currently marketed in Europe at a price of €66/kg and has a continuous refresh rate of around 50% (1 part for 1 part). Partner customers already started producing parts using BLUECARE in January 2021: this is the case of the IDPRINT 3D printing service in France, and the OCEANZ printing service, based in the Netherlands.

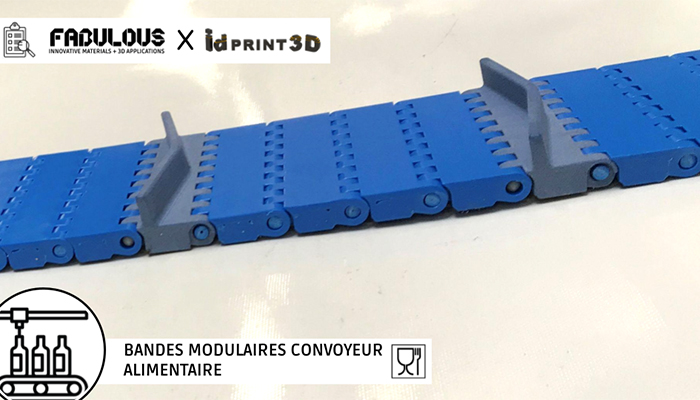

Application of BLUECARE powder by the company IDPRINT 3D (photo credits: Fabulous)

The first applications of Bluecare

In the case of IDPRINT 3D, BLUECARE powder was used to design 30 cm wide modular food conveyor belts. A success according to Mr. Panchot, manager of IDPRINT 3D, who believes that the material is perfectly adapted to his needs: “BLUECARE is the ideal material for additive manufacturing of parts for food conveyors, avoiding the manufacture of a mold that is too expensive for the number of parts to be made.”

At OceanZ, Fabulous’ material was used to manufacture food nozzles. “This nozzle is in direct contact with the confectionery. The confectionery contains sugar, so we need to avoid an abrasive effect on the nozzle. The BLUECARE material is one of the purest raw materials currently available for production. In addition, the material can be easily cleaned with cleaning agents after the production process. 3D printing with this material therefore opens doors for the food industry,” says Frank Elbersen, sales engineer at the Dutch company.

Nozzles made by OceanZ from BLUECARE powder (photo credits: Fabulous)

The “Safety and Security” range also includes TPU from 65 to 85 ShoreA, including a TPU certified for skin contact meaning it can be used as a medical grade material, thus ideal for the prosthesis, orthesis and orthopedics markets. Finally, a last TPU favoring the “rebound effect” completes Fabulous’ range. It is intended for the production of soles and shoes for the footwear sector.

Developments in line with the market

In its logic of responding to market needs, Fabulous has also decided to launch a new type of powder packaging dedicated to users of desktop SLS machines. “It will be more compact and better adapted to their needs,” explains Arnault Coulet. And the developer and supplier of materials does not intend to stop there. To enrich its “Safety and Security” range, other powder materials are already planned: a polymer-metal composite and a grade powder for the medical sector should be available by the end of 2021. In addition, Fabulous offers custom material formulation development services (from 600 kg) for companies seeking a material that is exactly right for their application.

In order to accelerate its development, both in terms of R&D and sales – the French company has the American market in its sights with FDA certifications in progress – Fabulous recently raised funds from private investors. These funds will enable the company “to provide solutions to industry, to accelerate the development of 3D printing with materials that really meet the application needs of end-users” concludes Arnault Coulet.To find out more about Fabulous, visit its website HERE.

BLUECARE is marketed in Europe at a price of 66 €/kg (photo credits: Fabulous)

What do you think of BLUECARE? Let us know in a comment below or on our Linkedin, Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.