Blood vessels 3D printed with sugar

At Rice University, in order to print complex 3D shapes, researchers use not polymers or metals but sugar! An ingredient that could have a particular impact on the medical sector and the understanding of our cells: indeed, with powdered sugar, the team explains that it was able to manufacture complex networks of branched blood vessels on which it managed to keep densely concentrated cells alive for two weeks. By mimicking the vascular networks, the researchers hope to provide oxygen and nutrients to multiple cells and thus provide long-term patient care.

The Rice University team has been studying blood vessels and tissue engineering for a number of years now. One of the biggest challenges is to design a large tissue structure that would be able to accommodate hundreds of millions of living cells. Ian Kinstlinger, a bioengineering student at Rice’s Brown School of Engineering, explains, “Providing sufficient oxygen and nutrients to all the cells in this large volume of tissue is a monumental challenge.” Nature is good at this, since the human body today has branching vessels, which are getting thinner and thinner, but more and more numerous, like the branches of a tree. This branching allows oxygen and nutrients to flow to cells throughout the body. Researchers have turned to additive manufacturing to replicate this mechanism.

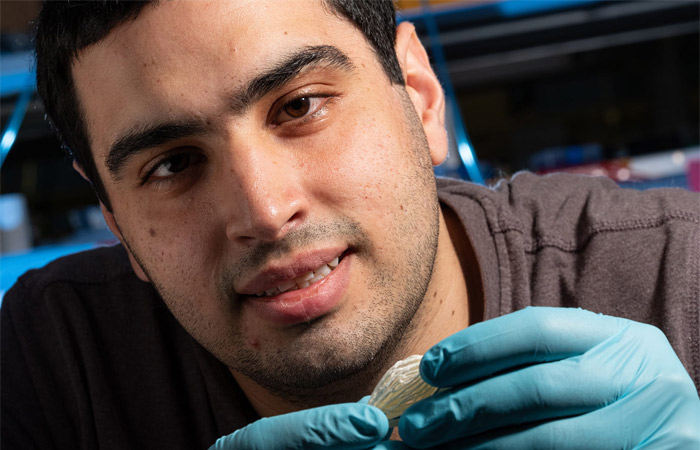

Ian Kinstlinger is responsible for several 3D printed blood vessels (photo credits: Jeff Fitlow/Rice University)

3D printed blood vessels using SLS technology

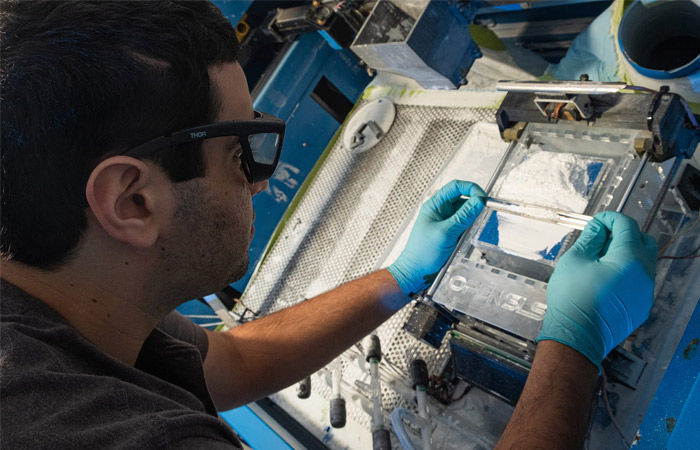

They first looked at a molten sugar extrusion process but realized that it could not create enough detail and complexity. So, they used a selective laser sintering process with a modified open-source laser cutter in the lab of Jordan Miller, an assistant professor of bioengineering at Rice University and a participant of the research. The technology would have allowed them to print sugar models on which they could build all sorts of combinations of cells and materials around them. The researchers actually poured a cell-laden gel into these structures, which serve as molds in the end.

Once the 3D printed sugar arrays are loaded, they are pumped with oxygen and nutrients. The vessels are able to power the cells for two weeks. For this test, the researchers used liver cells from the liver, which are particularly difficult to keep out of the body, thus reinforcing the success of the scientists’ research.

Using SLS technology (photo credits: Jeff Fitlow/Rice University)

Why sugar?

That’s probably a question everyone is asking. Ian Kinstlinger explains that sugar is long-lasting when dry and can dissolve quickly in water without damaging neighbouring cells, which makes it particularly interesting for printing blood vessel models. Several types of sugar would be mixed together to make the final printing material. Once the part is injected with the liquid gel, the sugar is dissolved and evacuated to leave a passage for nutrients and oxygen. Ian concludes: “A major advantage of this approach is the speed at which we can generate each tissue structure. We can create some of the largest tissue models ever demonstrated in less than five minutes.”

The researchers have also reportedly developed a custom algorithm to generate large, highly complex arrays and ensure they can be properly printed using the new technique. An algorithm designed in collaboration with the Nervous System design studio. You can find more information HERE.

What do you think about blood vessels being 3D printed with sugar? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!