Can Blender Be Used for 3D printing?

Created in 1995, Blender is a complete 3D modeling software, very popular in the world of animation and video thanks to the many features it offers. The particularity of Blender is that it is 100% free, open source – which is why it is constantly being improved – which allows it benefits from a large community that regularly meets around the world to share best practices and user challenges. Based on polygonal modeling, it is not necessarily the most widely used solution in the additive manufacturing sector, but it does allow 3D models to be exported in formats adapted to the technology. Let’s take a closer look the main features of the Blender software!

The software brings together various functions grouped into a dozen or so families: modeling, animation, simulation, video editing, 3D rendering and more. It is geared more towards animation studios, artists and small teams working in video or film – in fact, several “Open Movies” have been made using Blender.

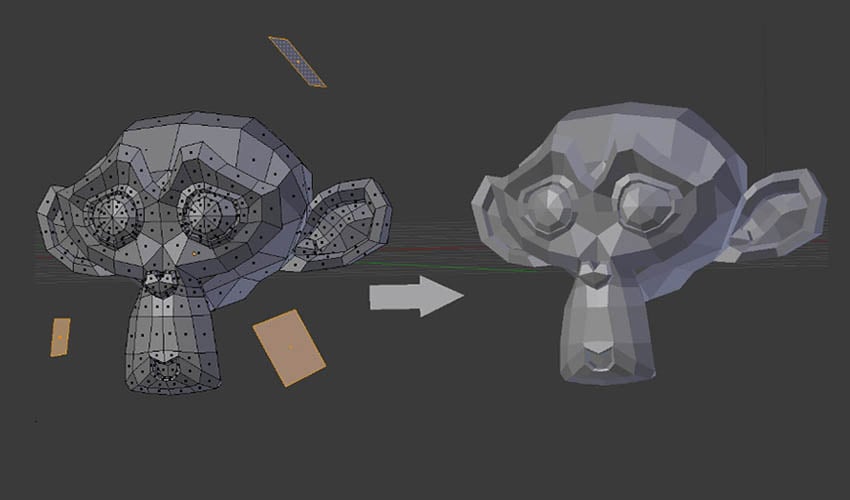

Blender is based on polygonal modeling

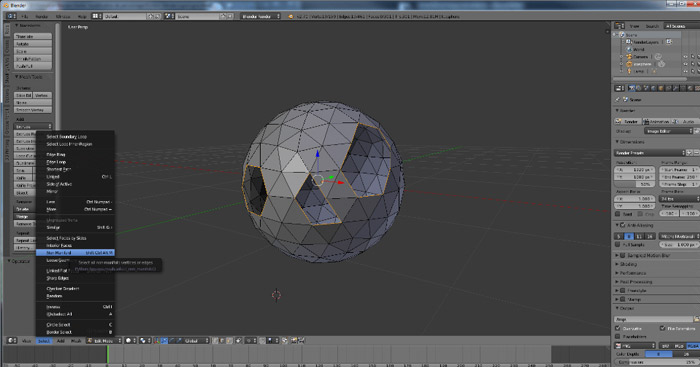

As you know, 3D software offers different modelling methods: surface, solid and organic. Here, Blender uses polygons to create a three-dimensional shape. The designed model is therefore composed of a multitude of polygons (or facets) that form what is called the mesh. This is the basis of the design.

Each polygon is composed of vertices, edges and faces. By assembling different polygons, a basic shape is obtained: for example, interlocking 6 polygons will form a cube. The next step is to deform basic shapes, and to join them together to design basic objects: nine deformed cubes will become a chair, for example. The user can then play with the edges and move points to progressively add complexity to the model.

Software Features in Blender for 3D Printing

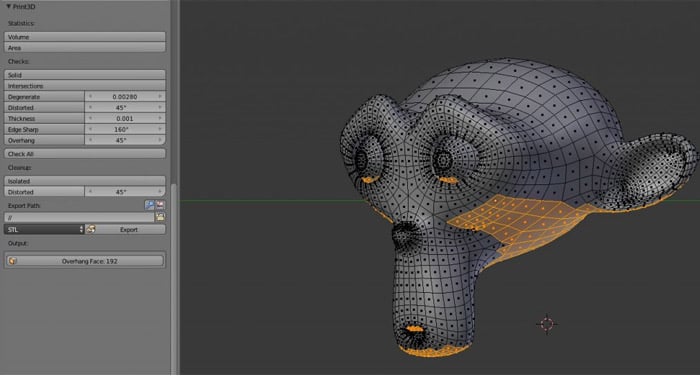

Although Blender has supported 3D printing modeling since 2002, version 2.67 has enhanced the functionality of 3D printing models. Of particular interest is the 3D Printing ToolBox. In particular, it allows you to analyze your mesh to identify certain errors that could cause your printing to fail. For example, this toolbox can check the minimum thickness of your walls or the geometry of overhangs.

The software also offers export formats for additive manufacturing, such as STL and OBJ files. Even if, at first glance, the software doesn’t appear to be the most attractive solution for 3D printing, it is nonetheless appreciated. Dutch artist Dolf Veenvliet, for example, uses Blender to design his 3D-printed sculptures.

The ‘3D printing toolbox’ enables you to check your model before 3D printing

Blender is not the most popular 3D software for 3D printing enthusiasts, but it does have the merit of being free, open-source and regularly improved by its community. We recommend more accessible software for beginners, such as TinkerCAD, and Fusion 360 for the more experienced.

New Version 4.0

The latest version of Blender, 4.0, was released on November 14, 2023. Although it introduces some general new features, these are not specifically designed for modeling for 3D printing. One of its new features is the addition of light linking, a long-awaited function that allows lights to be adjusted so that they do not affect all elements.

On the whole, these new features bring improvements, but their benefits are more pronounced in video and animation than in the creation of models for 3D printing. Blender remains compatible with Mac, Windows and Linux operating systems, and can be downloaded for free HERE.

Do you use Blender? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

I use blender to make all my 3d prints. The only downside is the ambiguity of the units. I’ve never been able to tell what size it will be until I load the model into my slicer would be nice if there was a fix for this.

Aparently there is, I am looking to use blender for 3D designs and all that is needed is to change the default size units from Metres to MM (Milimeters and your done. Hope this helps

I actually design all my models in blender. It works well enough for what I’m doing. Which is not printing art, but mostly very basic shapes for small speaker grills and the like to go on my electronics projects.

I have never ever faced issues with accuracy. In fact, I don’t even know where they’d come from since I can design an accurate model, so why shouldn’t it print accurately.

The main reason to use blender for me was that I knew it already, though. I’ve made (or tried to make) photorealistic scenes in it for years and just didn’t want to learn a new software.

Wow this article reads like you just discovered 3d modelling exists. Of course blender can be used for 3d printing. It has sculpting and regular modelling tools. It all comes down to the skill of the artist. The alternatives you mentioned are for CAD designing not standard 3d modelling. It’s like comparing forks to spoons.

I use Blender for 3d printing miniatures, characters, and action figures. The workflow of using primitives- booleans- remesh- sculpt- remesh- decimate is great for creating organic models to print.

Ive been trying to use blender for a 3d print project. Somewhat new to blender and very new to 3d printing in general. Blender is a bit painful to work with in few respects. Imagine trying to create an object like a bottle. It has curves and an inner/outer surface. Most tutorials sugest creating the outline and then either the spin tool or the screw modifier. Both options can generate a bottle like model. Ive also tried using a cylinder and extruding upward along a path. The model looks fine with all 3 methods. Then you try to bisect it and everything goes wrong. Its not a solid shape and bisecting reaveals all manner of artifacts. I want to basically split it down the center to create 2 parts. Then I want to add some pegs so the parts fit together. Once again Im relatively new to blender and a pro might bang this out in a few minutes. But for me Ill definitely try the above alternatives. This article describes the pitfalls of surface based modeling vs solid modeling and is the exact issue Im hitting. I have no confidence if I print my blender model it will work. Then again this will be my second 3d print ever. Thanks for the article.

Blender’s versatility as a 3D modeling software is truly impressive, especially considering it’s free and open-source. While it’s primarily geared towards animation and video creation, its polygonal modeling approach offers an intuitive way to design objects, even if it might not provide the highest dimensional accuracy for 3D printing. The addition of the “3D Printing ToolBox” feature is particularly useful for those looking to use Blender for additive manufacturing, as it helps identify potential printing errors. For beginners and those specifically focused on 3D printing, alternatives like TinkerCAD or Fusion 360 might be more straightforward, but Blender is undeniably a powerful tool in the right hands.