Bioprinting Under Pressure: 3D Printing Lung Models to Study the Effect of Extreme Environments

When pilots and astronauts go into flight, their bodies are pushed into environments far more extreme than anything experienced on the ground. To better understand how humans respond under these intense conditions, researchers at Texas A&M University, supported by the U.S. Air Force Office of Scientific Research, are turning to 3D bioprinting with living lung cells. Their goal is twofold: to enhance safety in aviation and spaceflight, and to accelerate the study and treatment of respiratory diseases.

Recreating Extreme Conditions

To accurately model how lung cells respond to harsh environments, the Texas A&M team needed highly controlled bioprinting parameters to ensure the cells remained viable. “Even small adjustments in the bioprinting process can dramatically affect cell viability and proliferation,” College of Arts and Sciences professor Dr. Hongmin Qin explained. “By fine-tuning these parameters, we are laying the groundwork for future breakthroughs in tissue engineering.”

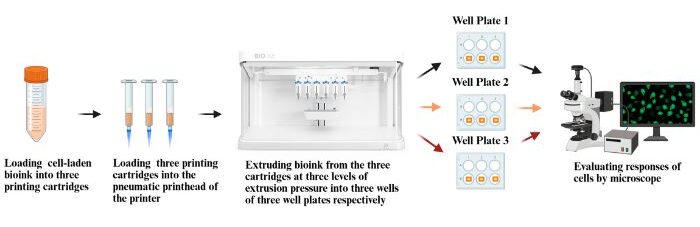

The researchers simulated extreme conditions through a series of targeted experiments. For one study, published in Biomimetics, the team varied extrusion pressure during printing. They found that higher pressures led to greater cell death. In another study, published in Bioengineering, they exposed the 3D printed samples to different temperatures up to 55 degrees Celsius. They observed that higher heat increased oxidative stress and reduced cell survival. “The pressure and temperature findings highlight the need for precise techniques to preserve the viability of lung cells in 3D-bioprinted samples, and demonstrate how the cells respond to environmental stressors,” Qin noted.

The team also created an optimized bioink formulation: a 4:1 collagen-to-alginate mixture that maintained an impressive 85% cell viability for six days, offering a promising foundation for future research.

3D Printed Lung Model Applications Beyond Aerospace

In addition to addressing national defense priorities, this project creates broad opportunities for medical research. By producing lifelike, 3D printed lung cell cultures, the team has created a platform for studying respiratory diseases such as chronic obstructive pulmonary disease and for accelerating drug-screening efforts. Looking ahead, the group sees using the same approach to produce bioengineered tissues on demand.

Overview of the experimental design demonstrating the effects of extrusion pressure. (Image Credits: Taieba Tuba Rahman et al).

This work parallels advances elsewhere. Earlier this year, researchers at McMaster University in Ontario developed a bioink that reproduces the elasticity and stretchability of lung tissue, making it well-suited for modeling conditions like COPD and pulmonary fibrosis as well as toxicity and drug-response testing. Also this year, the Science & Technology Division of the U.S. Department of Homeland Security, together with Wake Forest Institute for Regenerative Medicine, used 3D printed lung tissue to analyze the effects of toxic fumes on human health. Together, these projects underscore that biomimetic 3D models are becoming practical platforms for diagnostics, toxicology, and therapeutic development. To learn more, read the article from Texas A&M here.

What do you think of the study? Let us know in a comment below or on our LinkedIn and Facebook pages. Plus, sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Image Credit: Deposit Photos